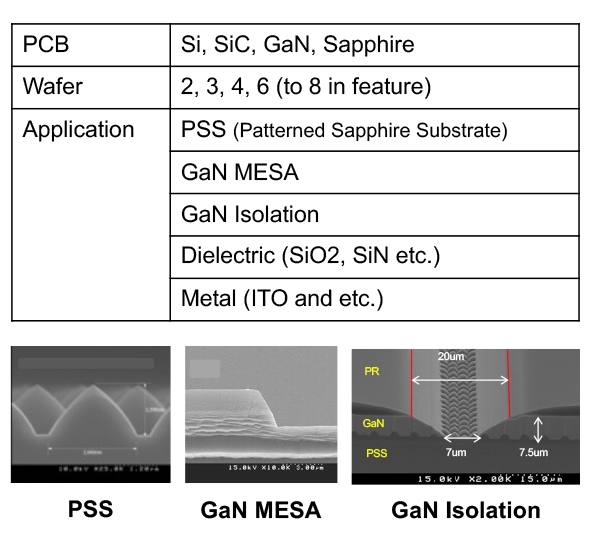

APX300 is a fully automated batch processing dry etching equipment that can simultaneously process multiple wafers of 6 inches or less and is capable of simultaneous processing of seven ø4" wafers and three ø6" wafers.

Features

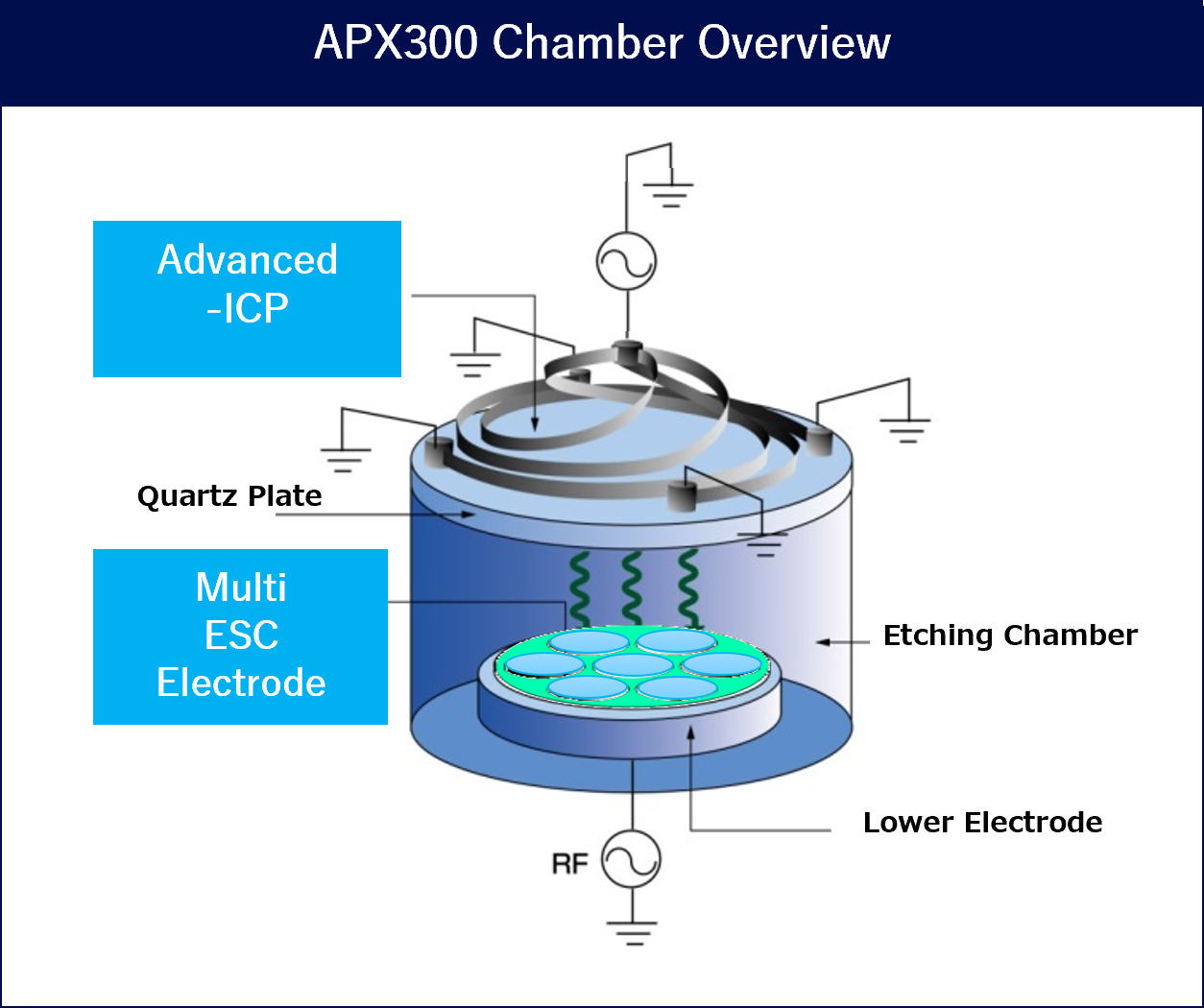

- High-accuracy and high-uniformity processing is possible using an original ICP plasma source

- An original batch ESC electrode is used to pick up individual PCB to realize high-accuracy high-speed etching processing at the single wafer processing level.

- Numerous achievements in the processing of compound materials, PCB materials, and insulating films

- Housing the device in one box contributes to increased area productivity

(Machine dimensions W 1350 mm x D 2230 mm x H 2000 mm)

Application

- Applicable to LT/LN PCB etching of SAW devices and etching process of protective film

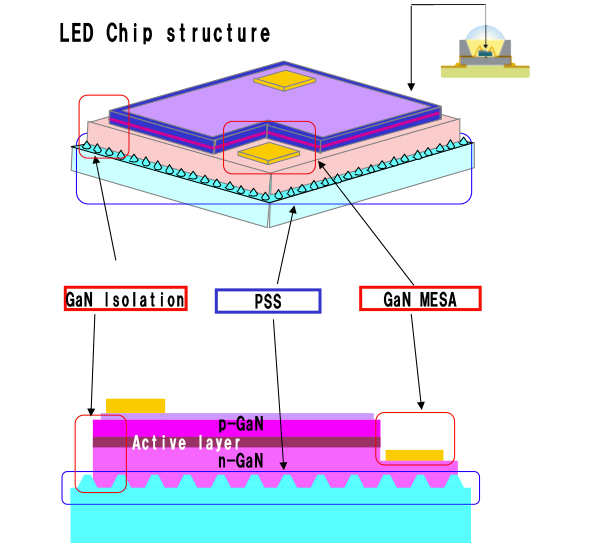

- High-speed processing of LED thin film contributes to high productivity in the etching process

- The PCB surface can be etched into shapes such as trapezoids and cones (PSS processing)

Key features and functions

- Advanced ICP realizes high accuracy & high productivity

- Multi number of wafers can be etched at once by by a unique batch ESC electrode,and and high-precision high-speed etching at the level of single-wafer processing is realized.

- Many achievements in the machining of compound materials, substrate materials, and insulating films

- Contributing to improved areal productivity through one-box equipment configuration

(Equipment dimensions W1350 mmx D2230 mmx H2000 mm)

The APX300 is a fully automatic batch dry etching system capable of processing wafers up to 6 inches in size. It can process 7 x 4 inch wafers and 3 x 6 inch wafers simultaneously, helping customers reduce production costs in the etching of PSS, GaN, insulating films, etc.

Demand for devices is expected to increase, especially in growing markets such as power semiconductors, optical and RF communications, RF modules, and MEMS. our company's batch processing technology will help improve production efficiency and reduce costs in these fields.

Advanced-MSC plasma source:

・High-efficiency coils with low inductance enable high-density,

high-uniformity, large-area plasma generation

・Wide discharge area can be maintained

•Multi-ESC Electrode:

・High cooling efficiency and high reproducibility are realized

by the ESC electrode that can directly adsorb each substrate

・Achieves high-speed machining and wide process window

About Dry Etcher

Examples of LED and power devices, and communication devices and MEMS and sensors

Information on current seminars and exhibitions is compiled and posted here. Information on past seminars and exhibitions is also available.