Key features and functions

- High productivity through support for model changeover and various types of automation during production

- Real-time monitoring of equipment status optimizes maintenance timing and expands production time

- Various functions for high-quality printing and stable printing that responds to 5M* changes to reduce defect losses

* 5M: The variable elements of a production site: huMan, Machine, Material, Method, and Measurement

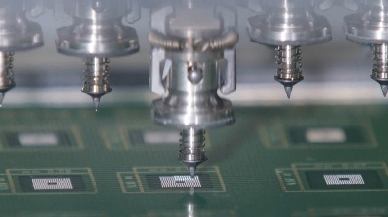

Automation of model changeover and other operations during production, together with appropriately timed maintenance based on equipment condition monitoring, contributes to increased production time. In addition, various functions to realize high quality printing, stable printing by responding to 5M changes, and M2M (Machine to Machine) with solder inspection equipment reduce defect losses.

High Productivity

High productivity can be achieved by switching models and responding to various types of automation during production.

High Printing Quality

Various functions for high quality printing and stable printing corresponding to 5M changes reduce defective losses.。

Solder transfer (option)

Solder on the mask is automatically collected after the end of production, and then the collected solder is automatically fed into the mask of the next model. The solder can be automatically transferred to the next model without losing the solder shape.

Automatic replacement of bottom receiving pin (option)

When switching models, the bottom receiving pin are automatically collected and placed.

Mask changer (option)

A magazine capable of stocking up to 10 masks is mounted at the rear of the equipment. After production is finished, masks are automatically stored in the magazine, and masks to be used in the next model are set in the equipment.

Automatic solder supply in a pot with hole (option)

Solder is automatically supplied through hole on the underside of the solder pot. Combined with a residual amount detection sensor, the solder on the mask can be maintained at the proper amount.

Paper-free wiping unit (option)

Cleaning without using cleaning paper or solvents. Paper and solvent can be reduced.

APC-5M (option)

Real-time monitoring of equipment condition. Optimize maintenance timing and expand production time.

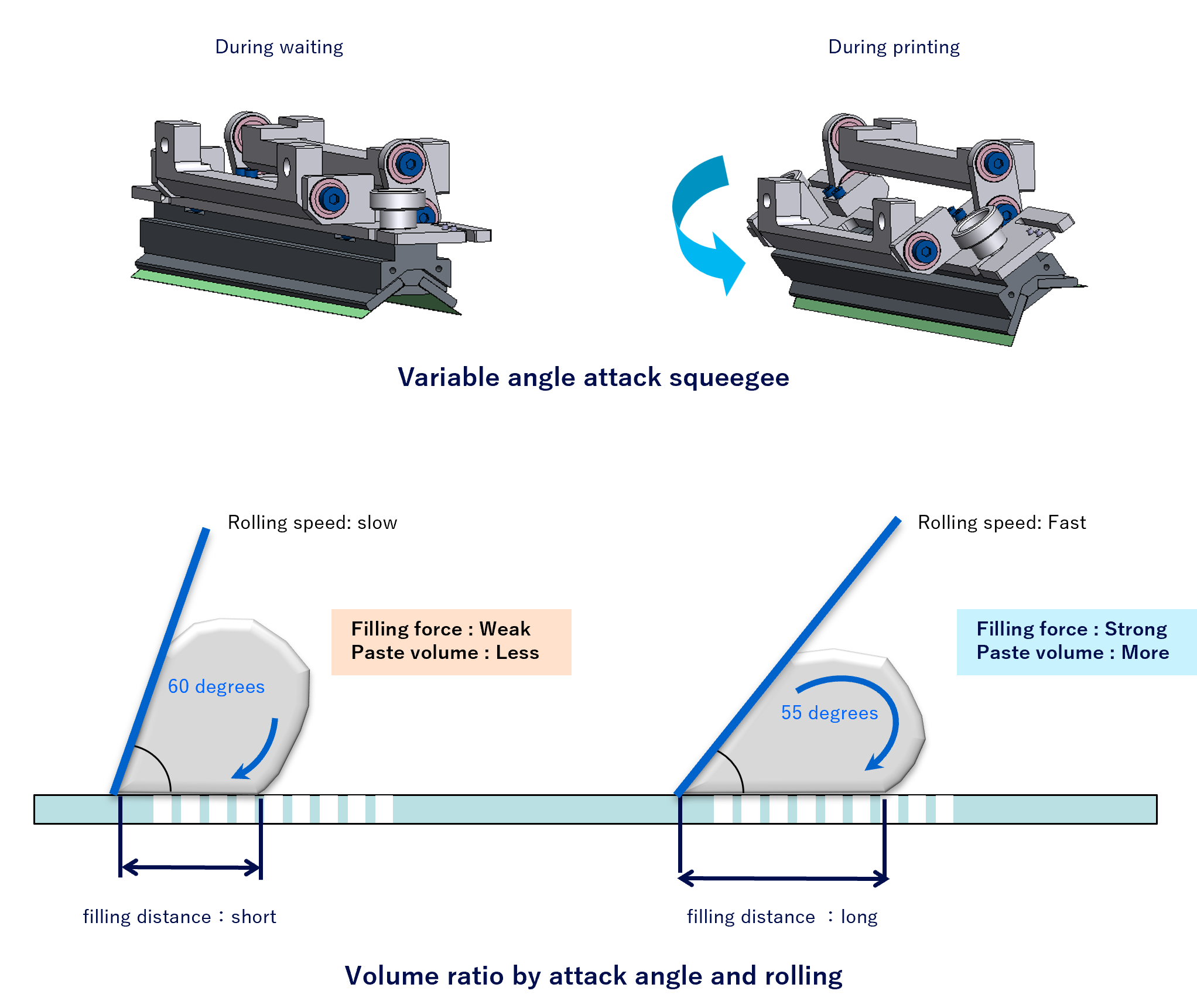

Variable angle attack squeegee (option)

The angle of attack can be set from 45° to 70° in 1-degree increments; in conjunction with the APC-FB (volume) function, the angle of attack is automatically changed.

Pre-bend High Filling Squeegee (option)

This metal squeegee has improved filling performance by bending the tip of the blade. It is as easy to handle as a normal metal squeegee.

Matching materials (option)

Mask, squeegee, lower receiving block, and solder are collated to prevent material setting errors. Stops the equipment in the event of a miscompare or unmatching.

Solder viscosity feedback (option)

The viscosity of solder on the mask is measured and controlled to maintain the proper viscosity.

Mask Tension Feedback (option)

Measure mask tension before printing and change plate separation operation.

Solvent Discharge Feedback (option)

Monitors the amount of solvent discharged during wet cleaning and keeps the amount discharged at the correct level.

Printing condition optimization control ( APC-5M ) (option)

Based on the SPI results, the printing pressure, squeegee speed, and plate separation speed are changed to achieve and maintain the optimum printing condition (volume).

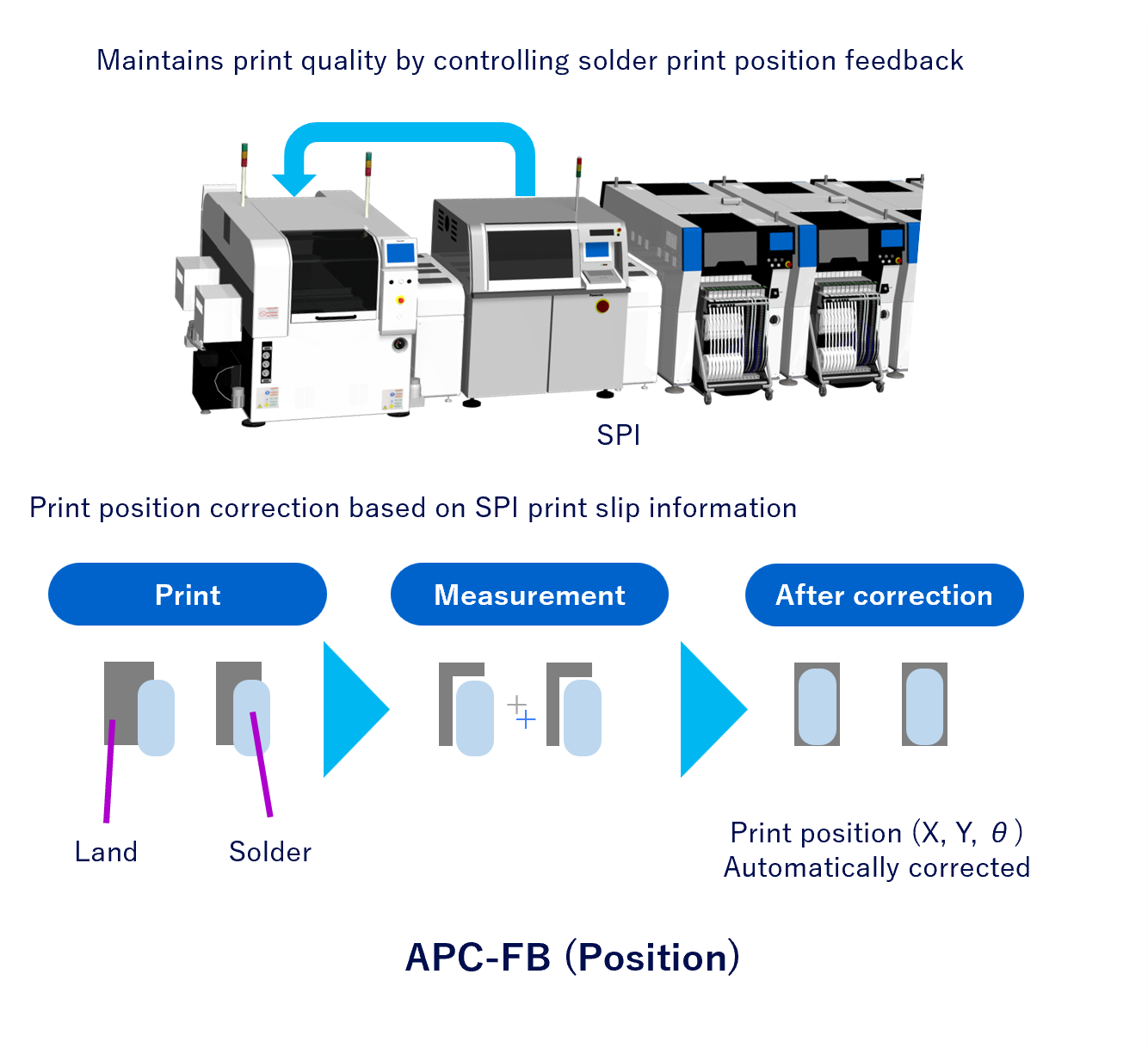

APC-FB (Position) (option)

Automatically corrects print position and volume based on SPI results. Two options are available: position correction and volume correction.

APC-FB ( volume ) controls volume by changing squeegee angle, thus smoothly leading to and maintaining optimal printing conditions.

*Variable angle attack squeegee (optional) is required.

*1 When "Paperfree wiping unit," "Automatic replacement of bottom receiving pin," or "Attack angle variable squeegee" is selected, the maximum substrate width differs. Refer to the "Specifications" for details.

*2 The substrate replacement time depends on the equipment of the preceding and subsequent processes, the substrate size, the use of the upper substrate presser, etc.

*3 Refer to the "Specifications" for mask specifications.

*The contents above are standard specifications. Please contact us for details as it may differ depending on usage conditions.

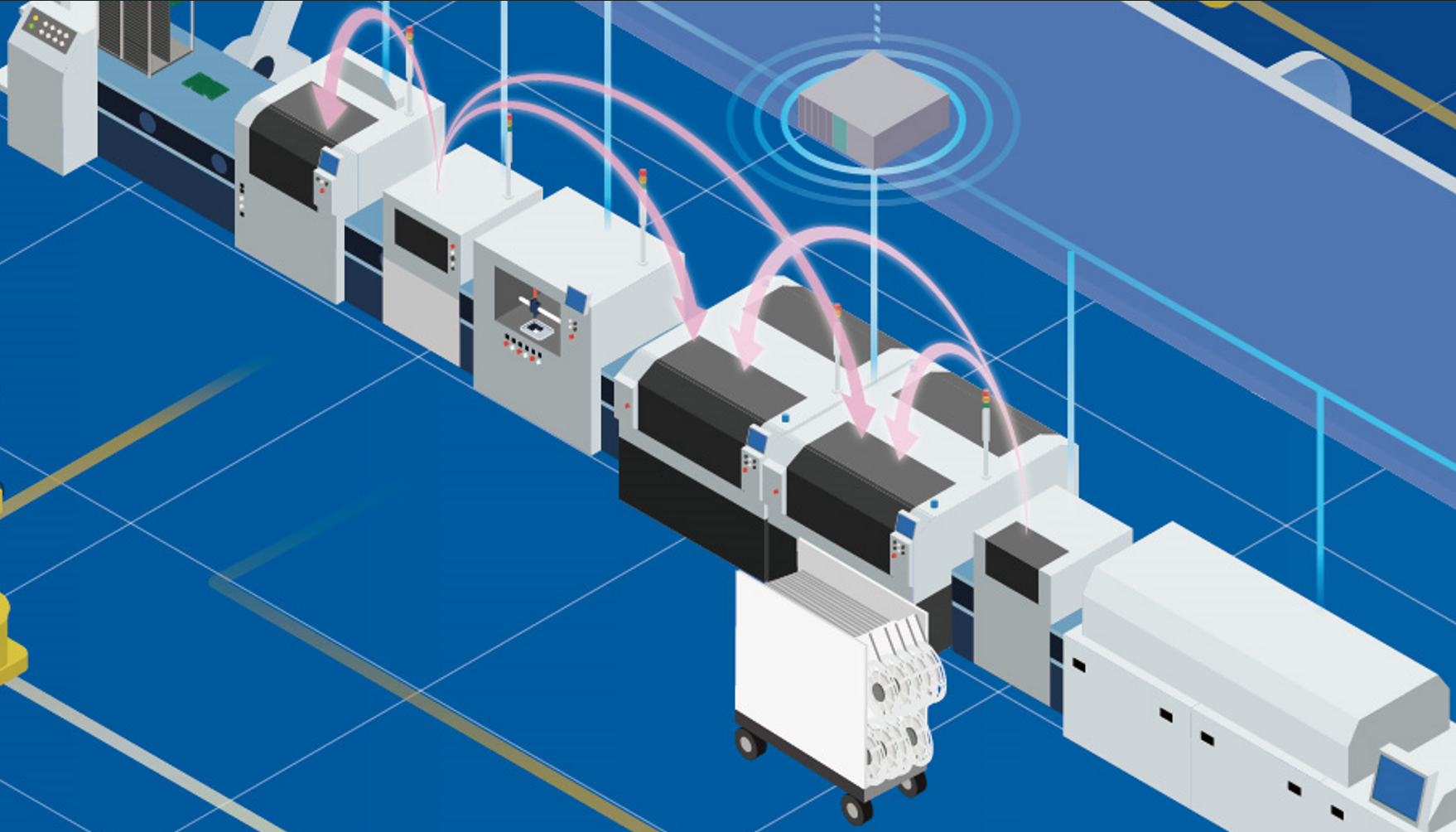

Installed MES software

PanaCIM-EE Gen2

Support is provided for improvement in QCD in each task related to mounting, through centralized management of the entire mounting floor.

Integrated line management system

iLNB

Optimization of the entire production line by “connecting” Panasonic machines, non-Panasonic machines, and higher-level systems.

Process control

APC-5M

Real-time monitoring of 5M variations in the core unit to achieve predictive maintenance that performs maintenance at timing that does not affect operation.

Information on current seminars and exhibitions is compiled and posted here. Information on past seminars and exhibitions is also available.

Line simulation

Tact simulation can be performed according to the mounted components and supply form.

Mounting feasibility study (nozzle selection)

We propose the optimum nozzle for the mounted components

Maintenance solution

To ensure that our mounting machines can be reliably used by our customers for many years after delivery, we not only maintain the machines, but also continue to support our customers throughout the life span of the machines, reducing production loss, stabilizing operation and improving work efficiency.