Key features and functions

- Narrow gap insertion is possible to realize high-density mounting, and capacity for large and heavy components is expanded

- New servo system extends the maximum tact travel distance and improves productivity by approximately 8% *

* within the maximum tact (0.14 s) compared to RL132

- Exclusive system solution for AI machines

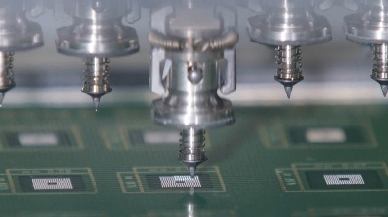

The 4P chuck allows insertion with the right and left edges as reference, and the 360 ° anvil rotation for narrow gap insertion, and the new insertion chuck and feeder increase the capability to handle large and heavy parts. In addition, the new servo system improves productivity in this high-speed radial part insertion machine.

High productivity

New servo system extends the maximum tact travel distance and improves productivity.

Versatility

Versatility enhancement due to narrow adjacent insertion and large and heavy components.

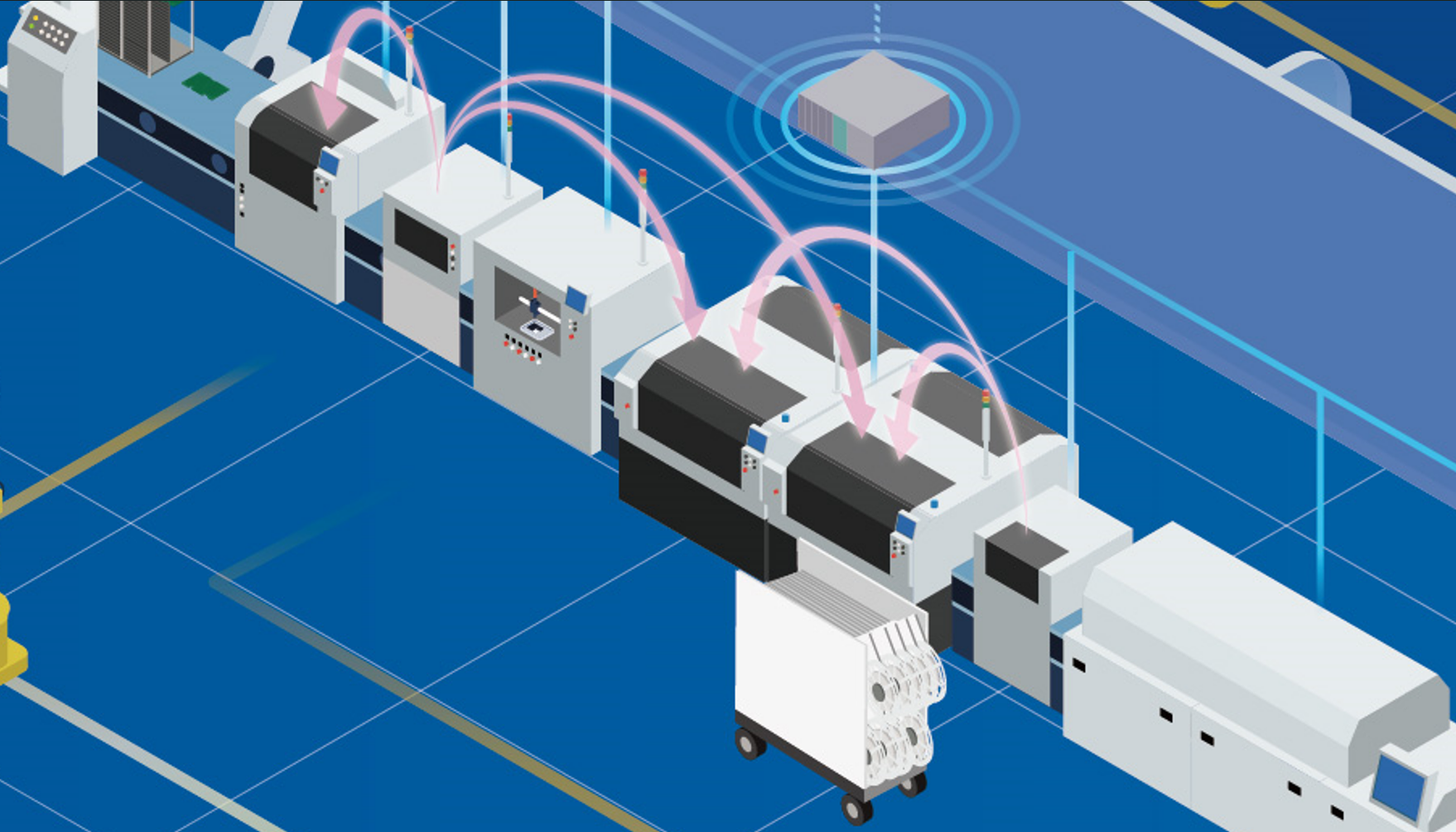

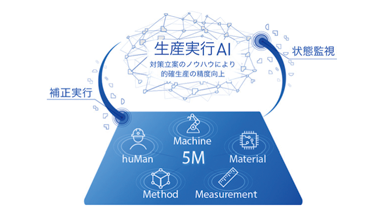

Exclusive system solution for AI machines

Reduce man-hours and improve O.E.E by linking software and facilities.

the maximum movement of the X-Y table within the highest tact time , 0.14 s , has been improved from 36 mm in RL132 to 40 mm. This is up to 8 % performance improvement compared to RL132.

( The highest tact time requires specific X-Y table movement , insertion angle , feeding conditions , and component size. Refer RL133 specification book for details.)

The 4 pitch specification has become the standard specification for the RL133. As a result, components with a wide range of 2.5 mm, 5.0 mm, 7.5 mm and 10 mm can be used. (RL132:3 pitch specification, 4 pitch specification are optional)

" Right and left edge reference chucking technology ( the first in the industry ) " and 360 °circular insertion enable high-density insertion , which was previously impossible at high insertion speed.

※ Based on Panasonic investigation by Jan 2025

”左右エッジ基準 チャック技術 ( 業界初※ ) ”と、360 ゜全範囲回転挿入により、従来高速挿入が不可能だった高密度挿入を実現します。

※ 2025年1月パナソニック調べ

RL133 supports large and heavy components by new insersion chuck and feeder.

Component height:max. 26 mm , Component diameter : max. 13 mm ( Option : 16 mm ), Taping weight:max 300 g / m ( Option :310 g / m )

新挿入チャックと新フィーダーにより大型・重量部品に対応します。

高さ:最大 26 mm 、 直径 : 最大 13 mm ( オプション : 16 mm )、テーピング重量:最大 300 g / m ( オプション :310 g / m )

The offline editor of the AR-DCE (Model No. NM-EJS4B) data creation system is a software that generates insertion machine data by performing model sorting and optimization considering line balance from CSV data easily using a personal computer. You can easily create, edit, and optimize insertion machine data offline without disrupting machine operations.

The connectivity options of the AR-DCE (Model No. NM-EJS4B) data generation system enable automated facility data extraction and storage, real-time data analysis and automation, and remote machine stop and interlock. These features reduce operator effort and improve operational efficiency. Analyzed data also helps identify process improvement points and improve O.E.E.

Odd-form Component Insertion Machine

NPM-VF

Automation of odd-form components insertion process. Various configurations of head tools and machine feeder configurations to adapt to different types of components.

High Speed Axial Lead Component Insertion Machine

AV132

Sequential component supply system with high-speed insertion at 0.12 sec/component and compact design.

High Density Radial Lead Component Insertion Machine

RG131/RG131-S

High-speed insertion of large-size components at 0.25 sec/component. In addition to 2-pitch, 3-pitch or 4-pitch specifications are selectable. Supports large-size PCBs as an option.

High Speed Radial Lead Component Insertion Machine

RL132

Achieves high productivity through high-speed insertion at 0.14 sec/component. Realizes various operation modes with the 2-part component supply system.

Information on current seminars and exhibitions is posted here. Information on past seminars and exhibitions is also available.