Issue

In the production of module products for automotive productts, high-mix low-volume production has been increasing and becoming more complicated in recent years. The creation of production plans required know-how and skills, and was time-consuming.

Solution

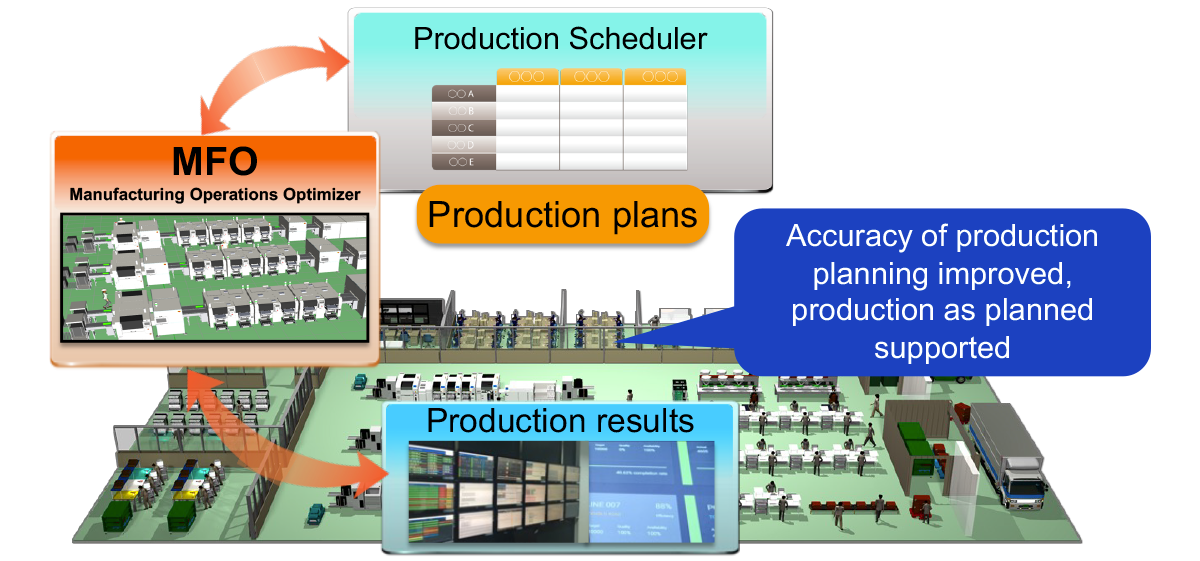

By introducing MFO, the creation of complicated production plans for the SMT floor could be automated, and the time required for production planning was also greatly reduced.

“We have automated production planning using MFO in Japan and will expand it to 11 overseas factories in the future. We would like to establish a system that management people can also constantly monitor the KPIs on a global basis.”

Background

Increased high-mix low-volume production, complicated production planning

"In recent years, the high-mix low-volume production has been increasing in the production of modules for automotive use. The production planning process has become more and more complex, and it takes a lot of time and requires know-how to create a production plan. In addition, there were many model changes, which resulted in long downtime, and production volumes were not increasing." (Mr. Miura)

Reason for introduction

To reduce production planning time

"In the case of high-mix low-volume production, there are inevitably many model changes. In particular, Alps Alpine uses a dual-lane line for mounting, which requires know-how and time to create production plans. We decided to introduce MFO after consulting with Panasonic in order to eliminate the need for human resources to create production plans." (Mr. Miura)

To improve the accuracy of production planning

"Making production plan and simulation is a very difficult and time-consuming process. With MFO, we can simulate automatically and accurately, which is why we decided to introduce MFO at our factory." (Mr. Sasaki)

Effects

Reduced production planning time and improved accuracy

“Before using MFO, it used to take me roughly half a day to do simulations and calculations, but with MFO I can now do the planning in less than five minutes. Although it is necessary to register the data in advance, we have been able to save huge amount of time and create highly accurate production plans." (Mr. Sasaki)

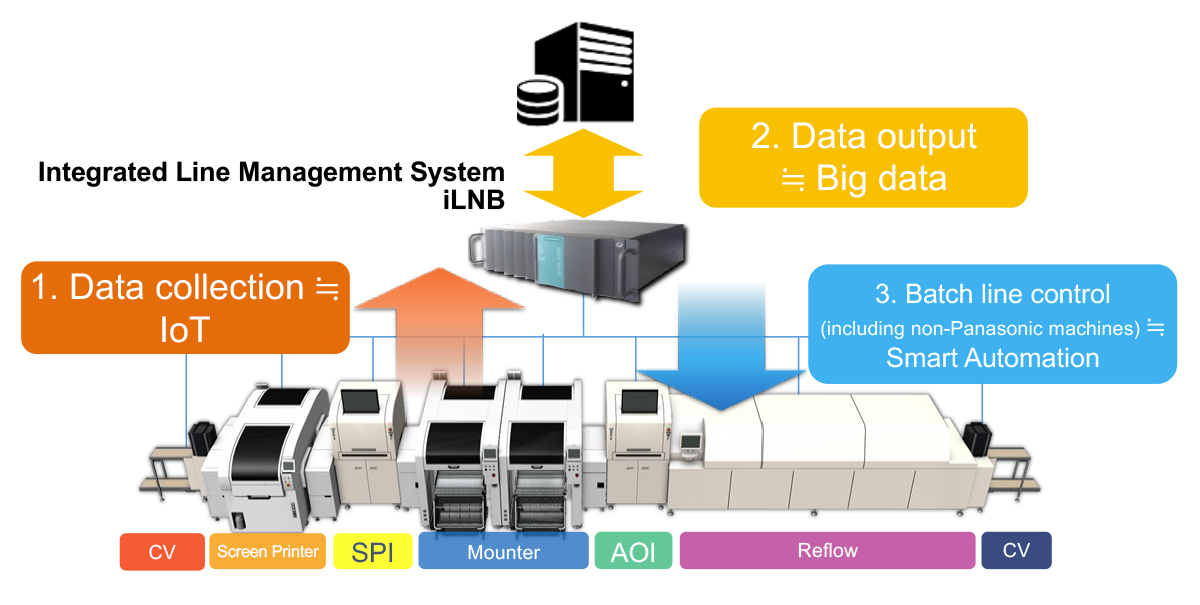

As for hardware, the latest screen printer and mounting machines are intruduced. Various SMT softwares are also being utilized to realize "automotive quality" and "labor-saving".

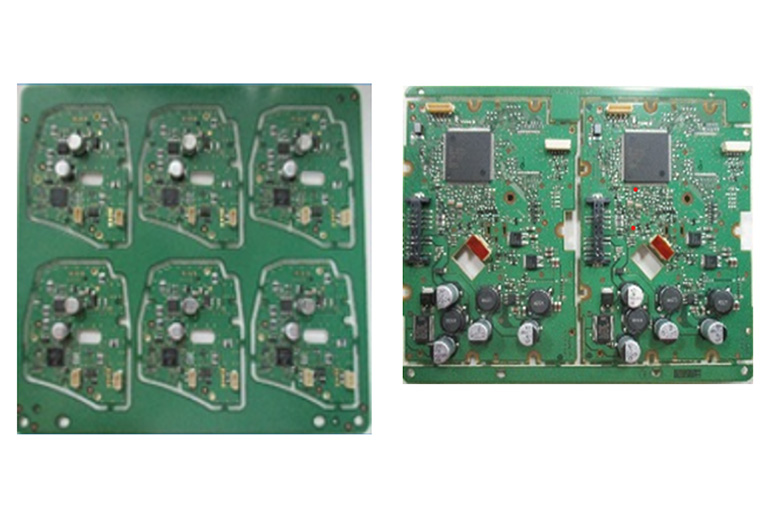

Modules for automotive use are mounting a wide variety of components to meet end-user's request. Also need to realize efficient high-mix low-volume production.

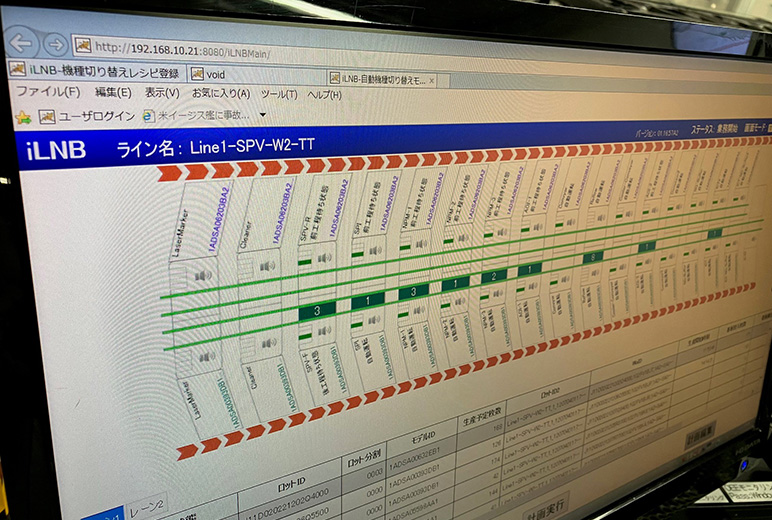

Introduced iLNB software to collectively control and manage the line by connecting with other companies' equipment. Frequent model changes were automated, significantly reduced setup time.

Case study video

Voice of customers

EV trend is a big opportunity, and ability to handle various components are important

“EV trend is progressing, and the number of electronic components used in cockpits is also increasing. Together with Panasonic, we are working to increase the responsiveness of parts and further promote automation and manpower saving through systems. Panasonic's "Autonomous Factory" concept is based on the same philosophy as ours, and we would like to continue to do our efforts while engaging in friendly competition through co-creation activities..”

<br />Assistant Manager,Domestic Automotive Manufacturing Dept

<br /><span class="small">*The organization/post was at the time of the interview.</span>

Realize "Automotive Quality" by creating system that does not rely on human

“MFO aims to optimize SMT floor, and we would like to improve MFO together with Panasonic. As for quality, it is very difficult to manage all the work that depend on 'people,' so we would like to create a system that facility side will ultimately manage everything ultimately.”

<br />Domestic Automotive Manufacturing Dept.

<br /><span class="small">*The organization/post was at the time of the interview.</span>

ALPS ALPINE CO., LTD. (Japan)

Furukawa Plant 2 is the largest manufacturing site in Japan, which began operations in 2019. It is equipped with environmentally friendly geothermal air conditioning and solar power generation, and is also a manufacturing site for automotive modules. As a mother plant that globally deploys production technologies cultivated in Japan, we are making improvements to enhance quality on a daily basis.

Click here for an estimation about Panasonic products.

Manufacturing Operations Optimizer (MFO)

The collected SMT floor information and parameters and PCB data are used to automatically formulate optimal production plans.

Integrated Line Management System iLNB

By “connecting” not only Panasonic‘s facilities but also other companies' facilities, we can optimize production for the entire SMT line.

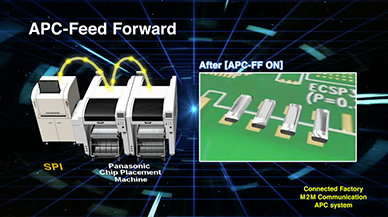

APC (Advanced Process Control) System

By connecting mounting machines and screen printers with an inspection machines, components can be mounted correctly at the targeted position.

Screen Printer SPV-DC

Enables high-efficiency dual lane production in a compact size, providing optimum functions for your production style.

Production Modular NPM-W2

A high production and high quality mounting model with improved productivity, model changeability, and component compatibility in variate production.

ALPS ALPINE CO., LTD. (Japan)

Manufacturing Operations Optimizer (MFO)

Automated planning of complicated high-mix low-volume production plans for SMT floors.

Improved productivity by automating production planning work that used to be personal.

Introduction: From 2020 Location: Miyagi prefecture, Japan