- Need to achieve miniaturization of module

- Need to achieve high speed at low cost

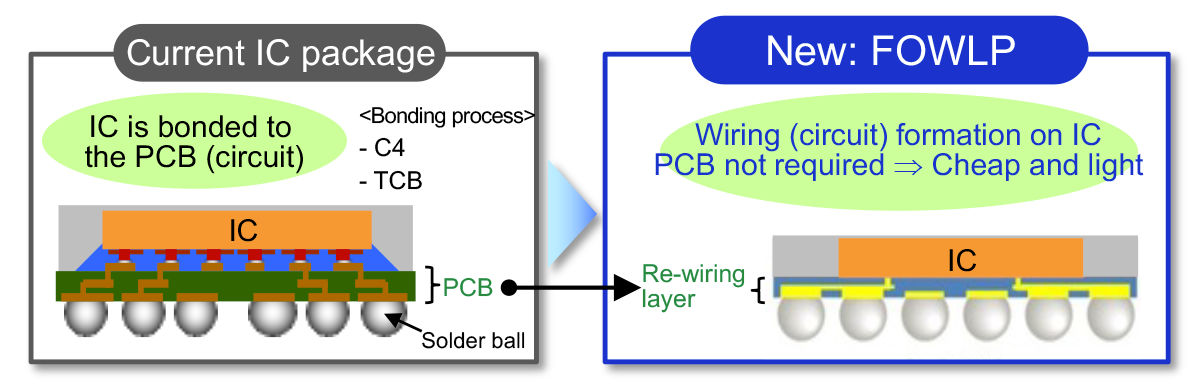

Compared to the method of bonding ICs on the PCB, FOWLP allows thinner designs by inserting a rewiring layer in the PCB layer.

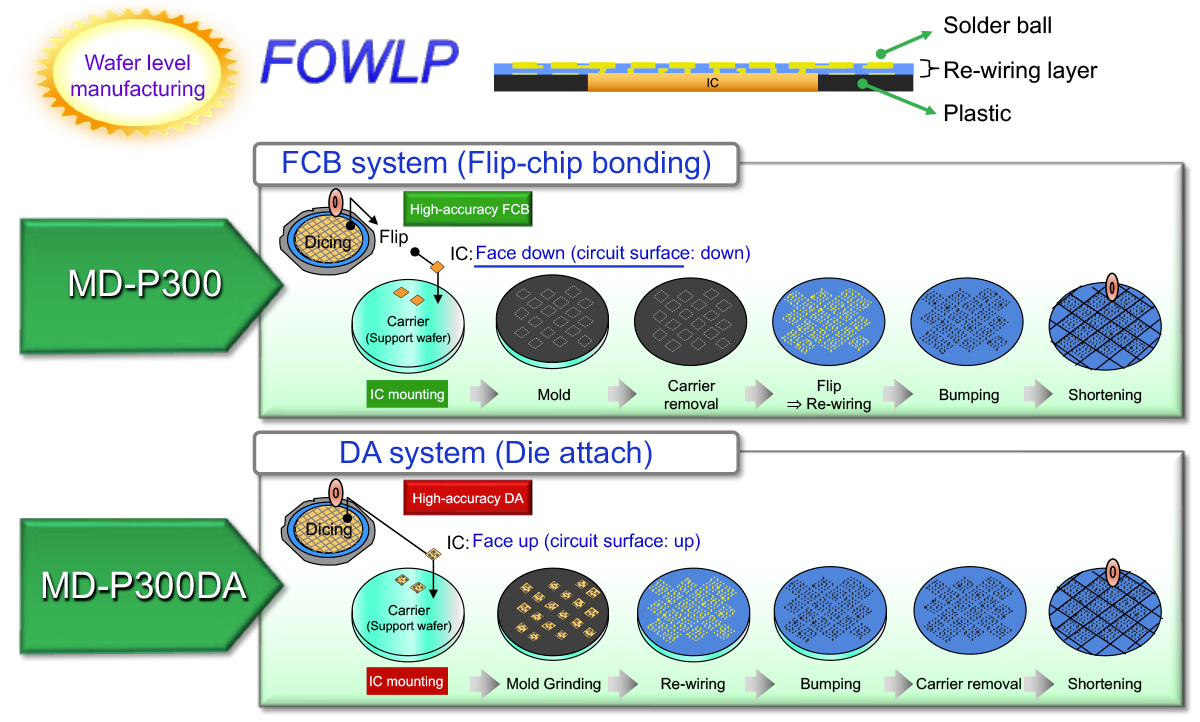

Bonder proposals in FOWLP

Flip-chip bonding method and die attach method are available.

Flip-chip Bonder

MD-P300

Supports φ300 mm wafer supply. Realizes high-speed and high-accuracy flip-chip bonding applicable to COW bonding too.

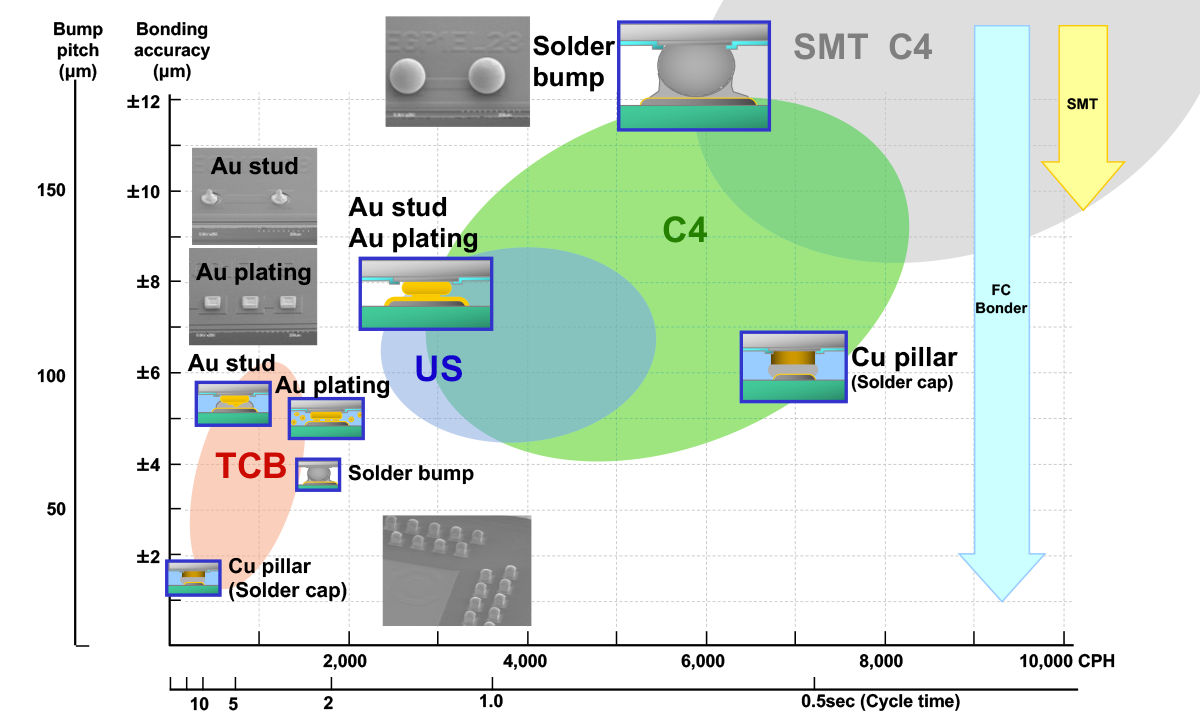

Flip-chip bonding (Ultrasonic bonding)

In flip-chip bonding, which achieves miniaturization, Panasonic has especially honed its ultrasonic (US) bonding technology. The MD-P200US2 specially designed for the production of small devices (SAW-F, TCXO, etc.), contributes to customers’ production with its unique US monitoring function and the fastest bonding speed in the industry.

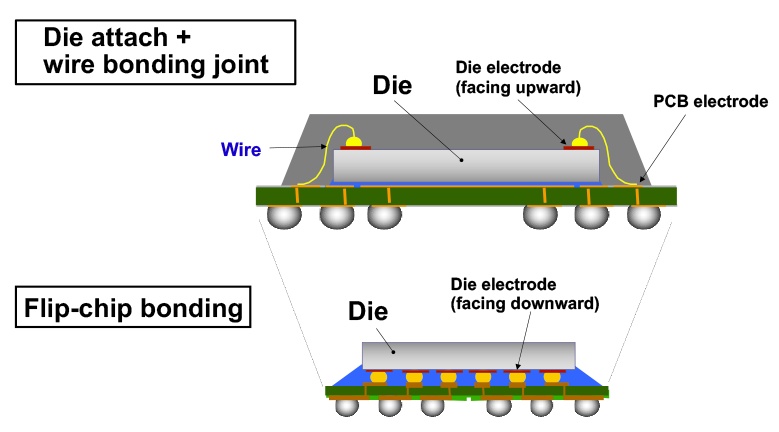

▲Difference in bonding methods

▲Bonding accuracy and productivity when ultrasonic (US) bonding is used

Die Bonder

MD-P200

Bonding device that is compatible with various bonding processes for state-of-the-art device assembly.

Flip-chip Bonder

MD-P200US2

Specialized ultrasonic flip-chip machine. Uses proprietary US tool and achieves a consistent quality.

Supports various bonding processes

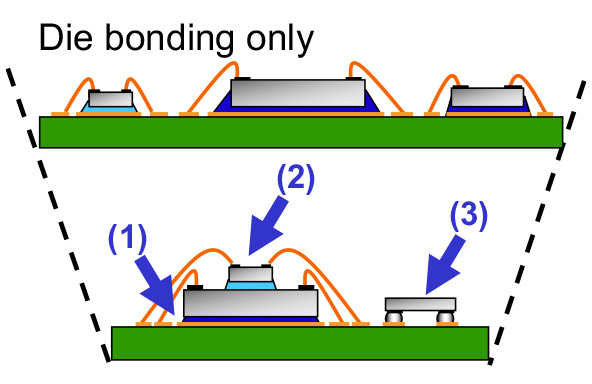

Compared to die bonding alone, this method achieves miniaturization, higher speed, and lower cost by supporting a variety of processes.

(1) Supports high-accuracy multi-die bonding

- Multi-die bonding of microchip dies in close adjacency on narrow pads contributes to module miniaturization

- Miniaturization contributes to cost reduction (base material, Au)

Die: Min 0.25 mm, Max 12 brands

Accuracy: DA; 15 μm/3σ

(2) Supports stack bonding

- Continuous stack bonding contributes to miniaturization of modules and lower cost by reducing intermediate heat treatment

- Miniaturization contributes to cost reduction (base material, Au)

Epoxy: Automatic switching of 2 brands

(3) Supports flip-chip bonding

- Contributes to miniaturization by less wire space

- Contributes to speeding up of processing by reducing wire length

- Contributes to cost reduction (Au→solder) by

C4 bonding

Accuracy: FC; ±7 μm/3σ

Die Bonder

MD-P200

Bonding device that is compatible with various bonding processes for state-of-the-art device assembly.