Campaign bands

Background colour

White

Section intro title

Do you face any of these problems?

Anchor link ID

PlazmaCleaner-01

Band body

- Need to improve bonding reliability of wire bonding

- Need to improve adhesion of underfill

- Need to improve flip-chip performance, solder bump performance, and die attach performance by cleaning/modifying wafers

- Need to improve the quality of solder bumps by removing resin residue on the wafer bump top

- Need to improve pad quality by removing plastic residue in via holes (desmear)

Background colour

Grey

Section intro title

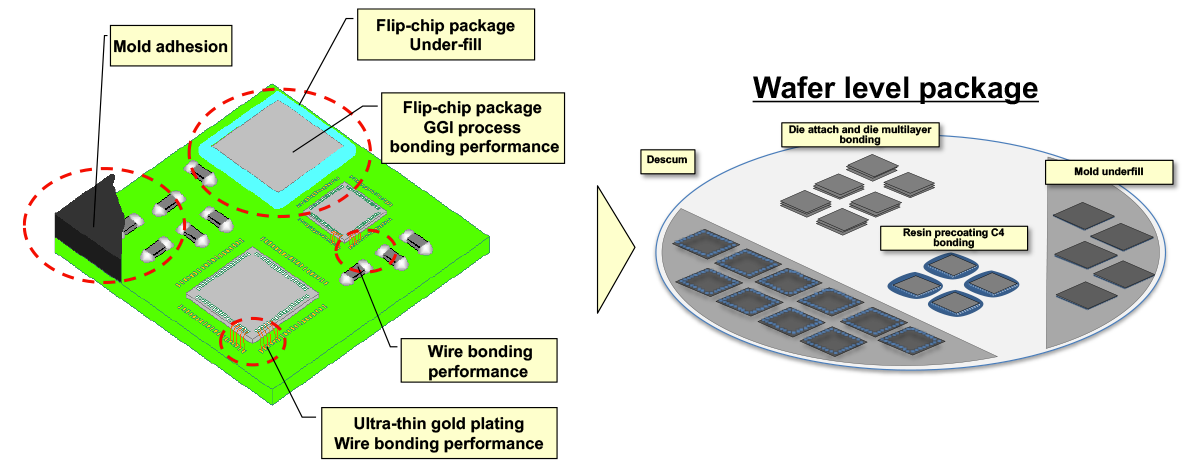

Our plasma cleaner contributes to quality improvement of various processes

Anchor link ID

PlazmaCleaner-02

Band body

▲Case studies of plasma application in packaging process

Media

Media

Background colour

White

Section intro title

Target machinery and target packages

Anchor link ID

PlazmaCleaner-03

Wysiwyg body

| Classification | PCB/Wafer application | PCB application |

| Model |

PSX307A |

PSX307 |

|---|---|---|

| Exterior | Contributing to wafer level manufacturing of up to 300 mm by taking advantage of high output, high productivity and damage-free treatment |

Contributing to device manufacturing processes by achieving high output, high productivity, and damage-free processing |

| Features |

|

|

Background colour

Grey

Section intro title

Solutions

Anchor link ID

PlazmaCleaner-04

Band body

Plasma cleaner application case studies for each process

Band intro title

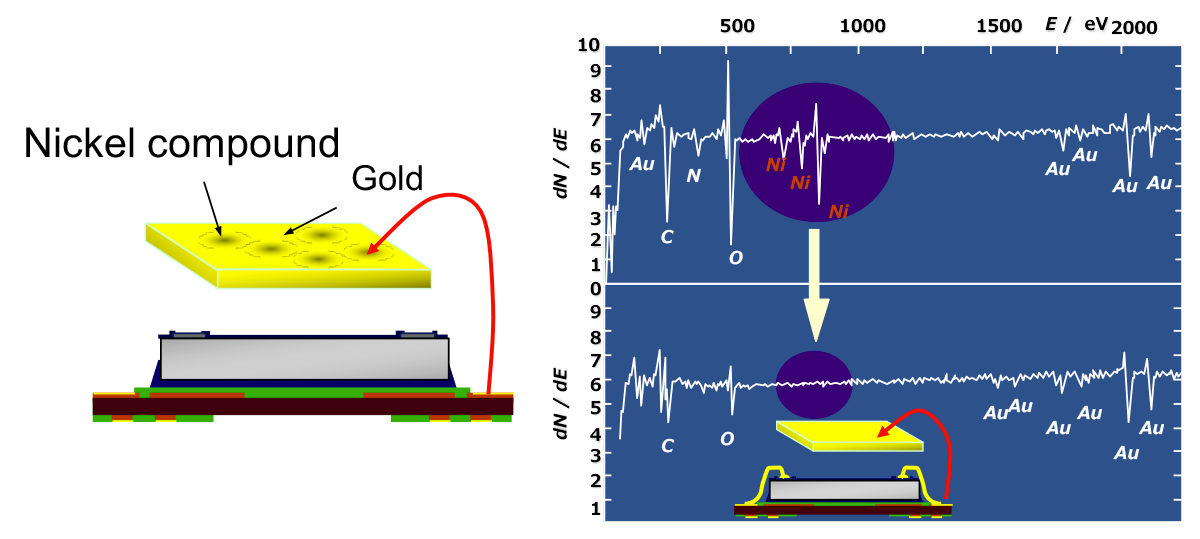

1) Ensures wire bonding can be performed on an ultra-thin gold-plated electrode for consistent quality

Media

Media

Band intro title

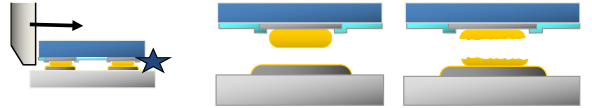

2) Ensures consistent bonding quality and improves bump retention in flip-chip, Au-Au and Au-Cu bonding by approximately three times

Media (max. 2)

Media

Media

Band intro title

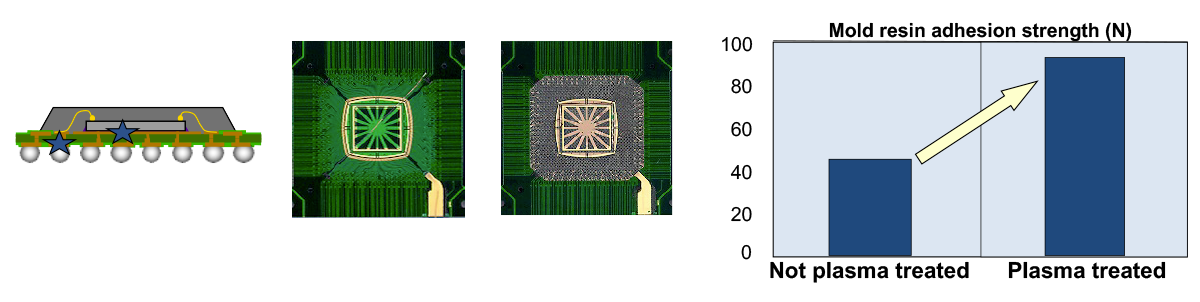

3) Approximately doubles mold resin adhesion strength, eliminates delamination and improves reliability

Media

Media

Band intro title

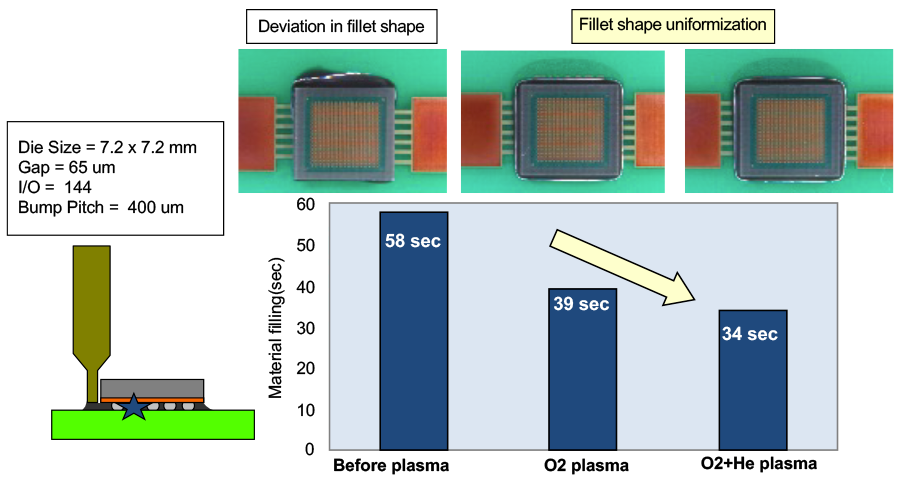

4) Reduces filling time by 40% and improves productivity. Ensures uniformity of fillet shape and improves void-free quality

Media

Media

Band intro title

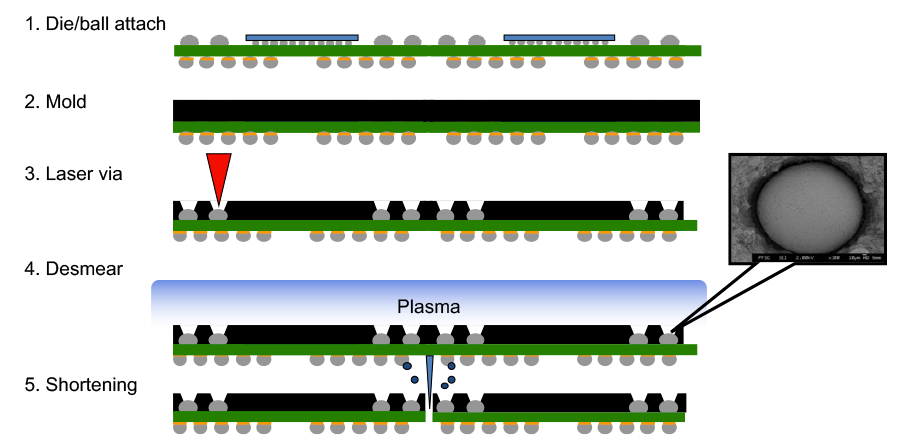

5) Remove the smear after laser via and improves PoP bonding

Media

Media

Band intro title

Related products

Column items

Column body

Media

Media

Column body

Media

Media

Background colour

White

Section intro title

Inquiries

Anchor link ID

PlazmaCleaner-05

Wysiwyg body

Campaign description

Do you face any of these problems? Our plasma cleaner contributes to quality improvement of various processes.

URL alias

/products-services_fa/solutions/device-related/plazma-cleaner

Use WYSIWYG header

On

Campaign header WYSIWYG

Plasma Cleaner [Solution]

Automate carousel?

Off

Display in-page navigation

Off