Campaign bands

Background colour

White

Section intro title

Do you face any of these problems?

Anchor link ID

PlazmaDicer-01

Band body

- Need to eliminate damage and chipping

- Need to achieve high productivity by batch treatment with plasma

- Need to suppress the occurrence of dust/particle that causes lower yields

- Need to design chip shapes freely

Background colour

Grey

Section intro title

Plasma dicer realizes high productivity by damage-less and clean dicing.

Anchor link ID

PlazmaDicer-02

Column items

Column body

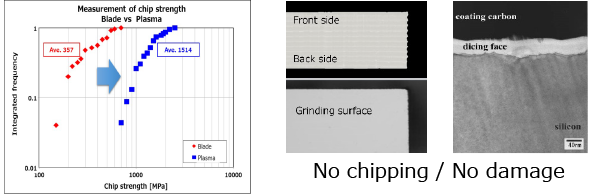

- Damage-free, chip-free and improved die strength of chip

- Thin wafer (≦50 μm) can be separated into pieces with low damage

- Capability that helps to separate into pieces with low device damage

Media

Media

Column title

1. No damage and no chipping

Column body

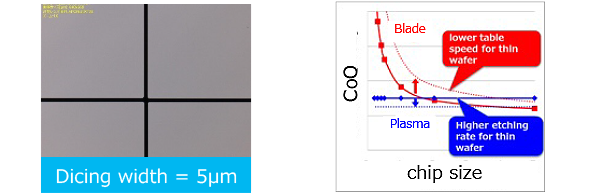

- Batch process treatment and high Si processing speed

- Narrow dicing widths (≦5 µm) and narrow kerf margins achieved by chipping or cracking allowing for more chips per wafer

Media

Media

Column title

2. High productivity and low CoO

Column body

- Chemical reaction processing by plasma etching, a clean process free from mechanical damages that generates mechanical dust, vibration and water pressure

- Capability to improve yield

- Potential to reduce the number of inspections and inspection points

Media

Media

Column title

3. Dust-free and particle-less

Column body

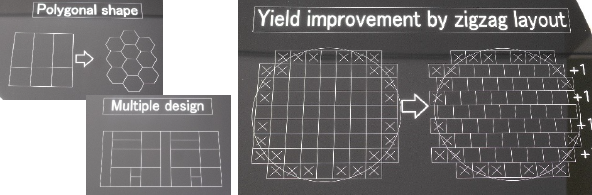

- No restrictions of chip shapes and layouts other than a grid

Media

Media

Column title

4. Various chip shape and layout support

Background colour

White

Section intro title

Target machinery and target packages

Anchor link ID

PlazmaDicer-03

Wysiwyg body

| Model |

APX300-DM |

|---|---|

| Exterior | Realizes damage free, takes more chips and improves productivity with the plasma dicing technology |

| Features |

|

| Target wafer |

Background colour

Grey

Section intro title

Solutions

Anchor link ID

PlazmaDicer-04

Band intro title

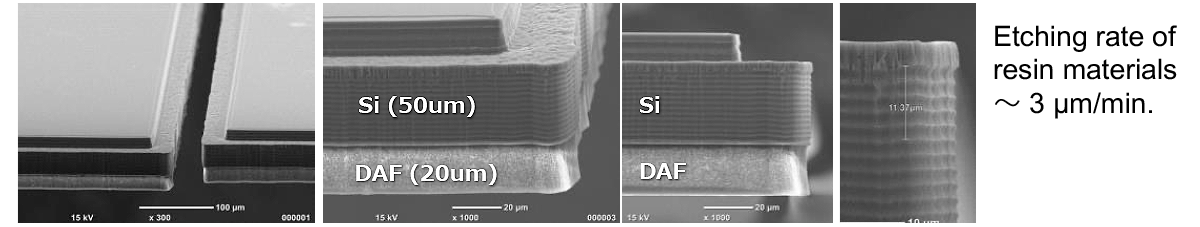

Plasma dicing of plastic materials like DAF

Band body

▲Process case study

Media

Media

Band intro title

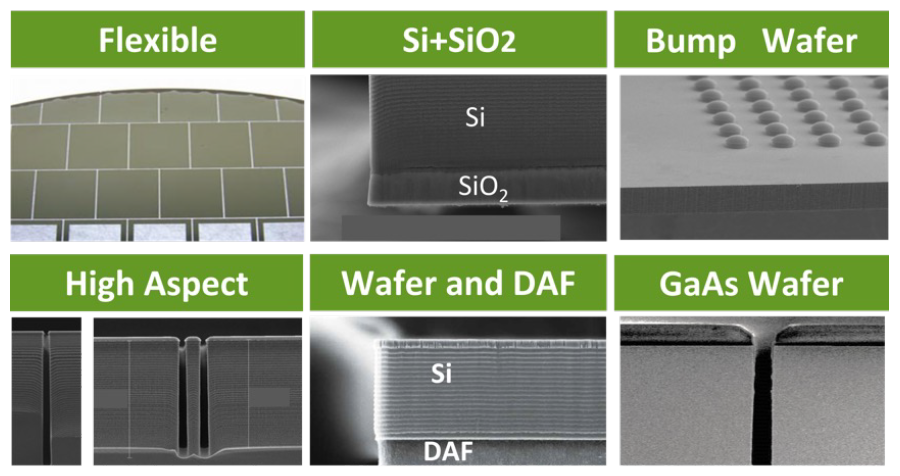

Plasma dicing of laminated wafer such as insulated film and WoW structure

Media

Media

Band intro title

Various other case studies of processing

Media

Media

Band intro title

Related products

Column items

Column body

Plasma Dicer

APX300-DM

Reduces damages, takes more chips and increases productivity with the next generation plasma dicing technology.

Media

Media

Background colour

White

Section intro title

Inquiries

Anchor link ID

PlazmaDicer-05

Wysiwyg body

URL alias

/products-services_fa/solutions/device-related/plazma-dicer

Use WYSIWYG header

On

Campaign header WYSIWYG

Plasma Dicer [Solution]

Automate carousel?

Off