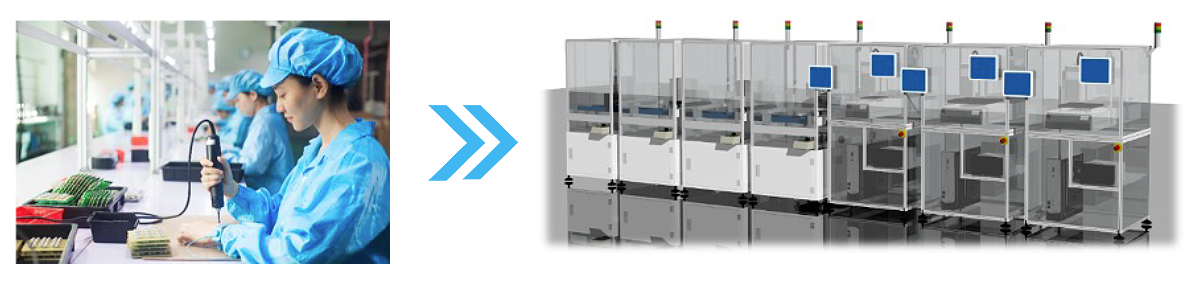

- Labor shortage in factory

- Unstable product quality due to manual work

- Manual work makes it difficult to track the production status

- Unable to establish a low-cost production process

We will introduce examples of automation solutions that replace manual labor with automated equipment in the mounting process and related areas.

* The solutions introduced here are produced by partner companies and are often available only in limited regions. Please contact us for details.

▲Automation

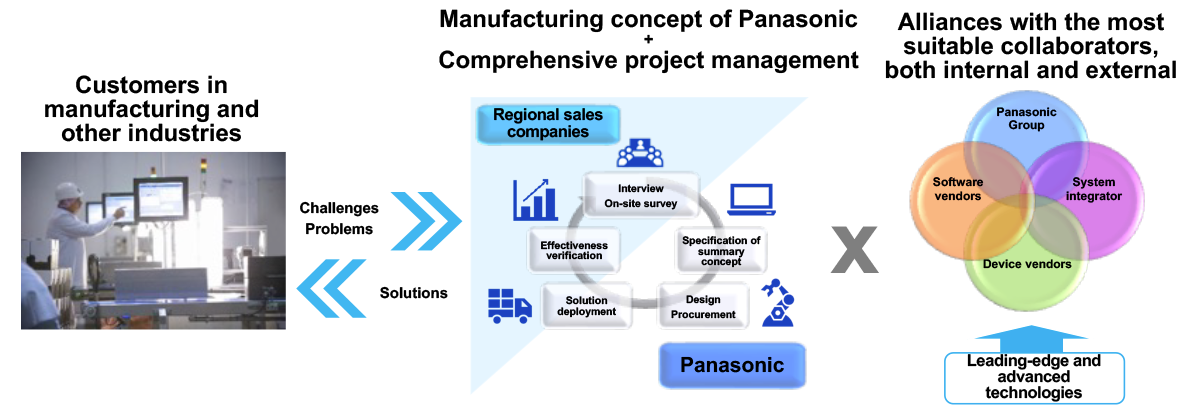

Panasonic’s role

We function as a production engineering solution provider.

Made by a collaborating partner

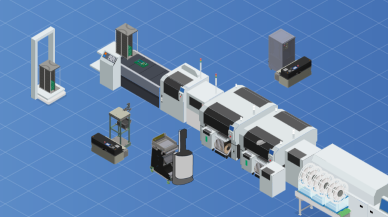

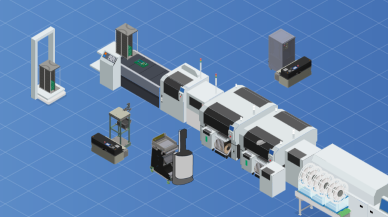

Using AMR/AGV, we propose a multi-transport solution for various objects such as feeder trucks, reel parts, and boards.

Made by a collaborating partner

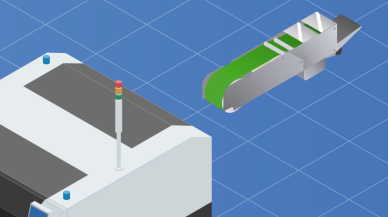

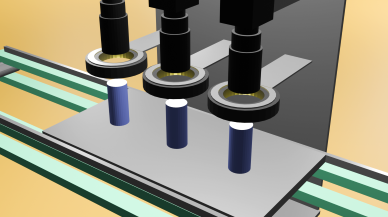

Enables supply of DIMM connectors /DIMM sockets to mounting machines.

Made by a collaborating partner

Device capable of automated supply of large-size components (DIMM connectors), placed alongside the mounting machines.

Made by a collaborating partner

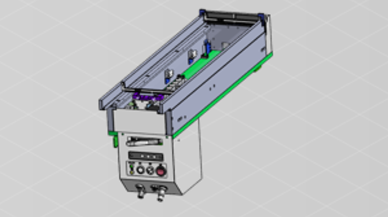

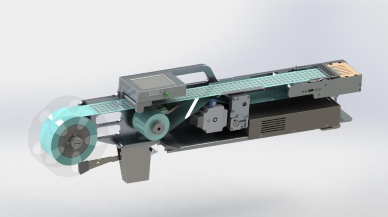

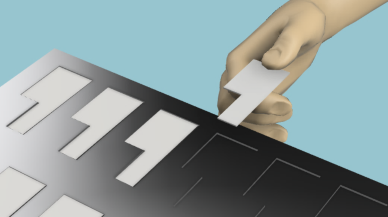

This feeder can supply plate-like workpieces such as metal plates and resin plates to the mounting machine.

Made by a collaborating partner

This feeder enables labeling work using the mounting machine.

Made by a collaborating partner

Do you have a request for a feeder that meets your needs? Please contact us and we will consider the design.

Made by a collaborating partner

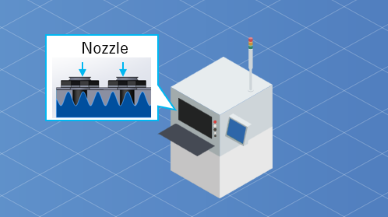

This single device performs nozzle cleaning and finish inspection as part of the maintenance of mounting machine nozzles.

Made by a collaborating partner

This is an example of high-precision odd-form component insertion using a SCARA robot that is capable of working alongside humans.

Made by a collaborating partner

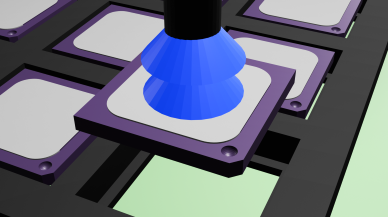

Automate the removal of IC chips from trays, placing them in testers, and visual inspection.

Made by a collaborating partner

The use of mounting machine enables automation of pick and place of non-electronic components such as metal plates and individual boards.

We will introduce examples of automation solutions that replace manual labor with automated equipment in assembly, inspection, and packaging processes.

* The solutions introduced here are produced by partner companies and are often available only in limited regions. Please contact us for details.

Made by a collaborating partner

Using AMR/AGV, we propose a multi-transport solution for various objects such as assembled parts, finished substrates, and packed products.

Made by a collaborating partner

This is an example of component picking, product handling, and transfer between processes in a transceiver assembly line.

Made by a collaborating partner

This is an example of PCB inverting, screw tightening, and fitting operation in a transceiver assembly line.

Made by a collaborating partner

Automates visual inspection using image recognition equipment. We can also propose AI inspection for customers who have already implemented image recognition but are having problems with poor detection accuracy.

Made by a collaborating partner

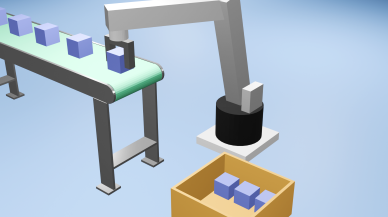

Automates the loading of workpieces into the packaging machine, packing of workpieces after packaging, and palletizing/de-palletizing of finished products.

Consult in detail about automation needs and issues

Discuss the target factory together

Provide the most suitable automation solution for the customer's factory

Propose new equipment development plan according to needs

Equipment import and installation

Panasonic provides overall support including after-sales service