In the PCB industry, mounting is mainly categorized into module mounting and motherboard mounting. With electronic components becoming smaller and thinner, the needs of module mounting are increasing, and mass production of 0201 components and high density with a spacing of 50 μm is required.

In terms of mobile compact terminals, such as smartphones and wearable terminals, the trend of system-in-package is further accelerating due to the increase in the number of components required to support higher functionality. Micro components and high density are required.

微小部品の実装には、印刷工程では高アスペクト比への印刷対応、装着工程では狭隣接実装が必要となり、更にはソフトウェアを活用した現場の状況に対応して補正を行うプロセスコントロールが重要になります。

私たちはハードウェアの設備単体だけでなく、ソフトウェアも含めたトータルソリューションをご提案いたします。

- 微小部品に関する印刷難易度と狭隣接実装

- 予測されるお困りごととソリューション

- 高アスペクト比に対する高充填印刷ソリューション

- 高精度・高生産実装機 NPM-GH

- 印刷・実装共に各種補正を行うプロセスコントロール

資料のダウンロードには会員登録が必要です。

会員登録後は弊社Webサイト上の資料を全て閲覧できます。

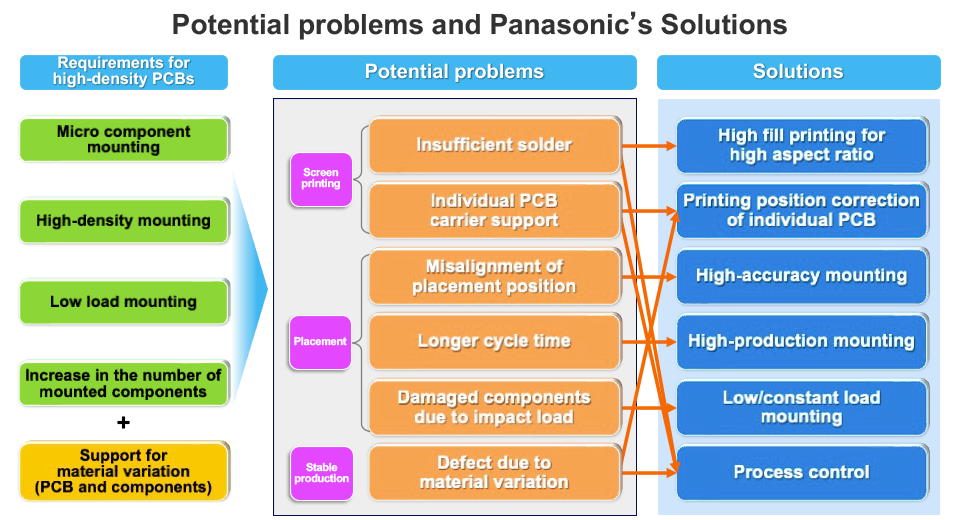

There are various requirements and a wide range of problems when mounting high-density PCBs.

We propose various solutions for these problems from the perspective of screen printing, placement, and stable production and help achieve high-quality and high-accuracy mounting.

Process solution for high-accuracy mounting

Components will become smaller in size with the progress in miniaturization, thinning and higher functionality progress. We provide process solutions to any difficulties you may experience when assembling 0201 components with a 50 μm spacing.

Proposal of a cutting-edge mounting system that achieves highly efficient production for the most difficult SMT PCBs

We introduce Panasonic's cutting-edge mounting systems, the NPM-X series and SPV-DC, especially for PCBs with a high level of difficulty in the smartphone/ICT, package and LED display industries.

Realization of chip downsizing and OEE maximization

We introduce NPM-GP/L, which realizes stabilization of printing quality of miniature and narrow adjacent parts and reduction of non-operating loss including cost reduction.

State-of-the-art mounting head technology that achieves high production, high-quality and high-accuracy mounting

We introduce the features of the high-speed head, general-purpose head, and multi-function head that Panasonic developed based on trends of products and electronic components in the market.

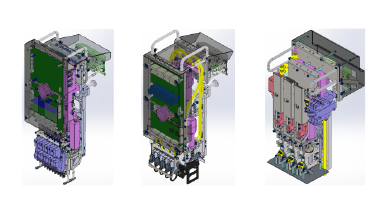

Modular Placement Machine

NPM-GH

This edge device achieves industry-leading productivity and mounting quality for Autonomous Factory. Proposes control of irregularities in the 5Ms and elimination of skill-dependent work.

Screen Printer

NPM-GP/L

Optimizes the screen printing process. Equipped with automation functions, also capable of high-accuracy screen printing.

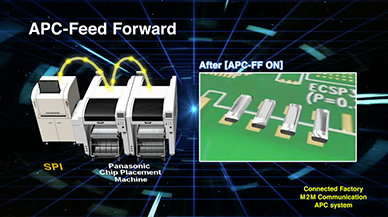

APC System

By connecting the visual inspection equipment and the placement machine after mounting, ensuring the mounting accuracy and identifying the causes for variation is possible.