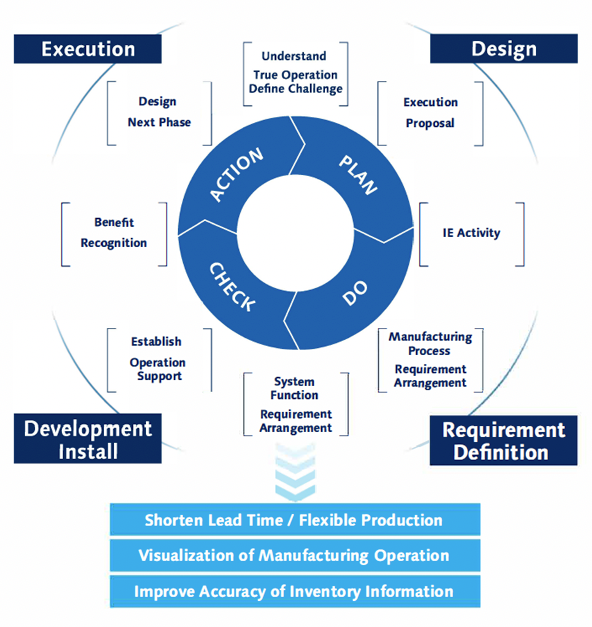

MOM refers to the management of manufacturing operations.

It aims to optimize overall factory operations and improve production efficiency by using various tools (hardware and software) for manufacturing operations from the warehousing of raw materials to the dispatching of finished goods.

The MOM System uses the following software tools to optimize factory operations and improve production efficiency

Production Scheduler

Asprova

Plans process that can be executed in a short period, taking into account worksite constraints.

Contributes to short manufacturing lead times, reduced in-process inventory, more accurate delivery responses and shorter planning cycles

Electronic Reporting Tool

i-Reporter

A paperless solution that contributes to cost reduction, operational efficiency and improved quality of operations by solving problems in hand-written reports

Visualization Tool

MotionBoard

Contributes to good-quality production through centralized management of items (feeders, nozzles and tools) used in SMD component mounting machines for circuit mounted PCBs

Simplified factory diagnosis

We identify issues at the worksite by listening to the opinions of the operators and understanding the flow from the warehousing of raw materials to the start of manufacturing, the final process, and the shipment of goods. In parallel, we confirm the information flow by interviewing production management, planning and IT workflows. Then, based on the identified issues and the causes, we propose ways to reduce waste and maximize time efficiency, etc. from a third-party perspective. Afterward, we develop targets with our customers and establish a starting point for improvement. We may use IT systems as a tool for improvement, or we may conduct activities of establishing operation standards at the worksite.

▲Simplified factory diagnosis in progress