Campaign bands

Wysiwyg body

Column items

Column subtitle

Solder printing defect

Column body

Achieving stable solder printing

Media

Media

Column subtitle

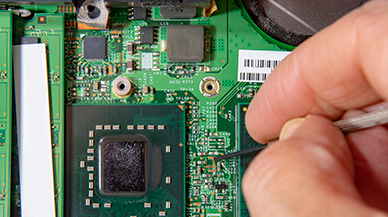

Electronic component mounting defect

Column body

Continue to improve and maintain mounting accuracy

Media

Media

Column subtitle

Improve mounting reliability

Column body

Electronic materials for mounting

Media

Media

Background colour

Grey

Section intro title

Solder printing quality improvement solutions

Anchor link ID

Quality-01

Band body

Achieving stable solder printing

Column items

Column subtitle

Pre-bent high fill squeegee

Column body

- Metal squeegee improves solder refill performance

- Refillability exceeds urethane squeegees

- Easy installation and high durability with no skill required

Media

Media

Column subtitle

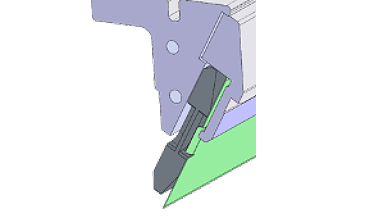

Solder leak prevention block

Column body

- Prevents lateral solder leakage on metal masks

- Simple structure for easy installation and cleaning

- No need to adjust the gap with the metal mask thanks to the movable guide

Media

Media

Column subtitle

Automatic solder feed

Column body

- Monitors solder amount and automatically feeds solder

- Enables long-term, continuous stable printing

- Reduces solder waste

Media

Media

Column subtitle

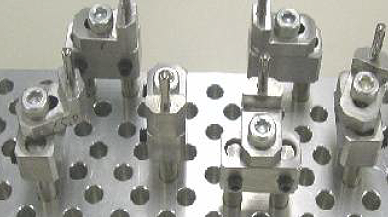

Universal PCB support pins

Column body

- Enables granular adjustment of support pin position

- Allows printing simply standing on a conventional PCB support unit

- No need for a dedicated support block for each PCB

Media

Media

Background colour

White

Section intro title

Solutions for electronic component mounting failure

Anchor link ID

Quality-02

Band body

Continue to improve and maintain mounting accuracy

Column items

Column subtitle

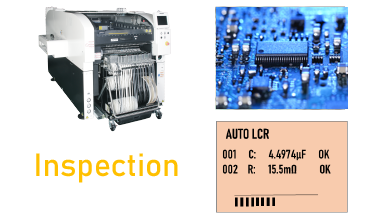

LCR checker

Column body

- Automatic constant checking before mounting

- Prevents incorrect mounting due to check mistakes because workers do not intervene

- Reduces constant check man-hours

Media

Media

Column subtitle

L/R mis-set check guide

Column body

- Useful for preventing component reels from being set incorrectly

- Easy to check for left/right reel mis-hangs, and prevents incorrect mounting

Media

Media

Column subtitle

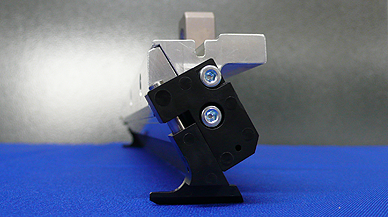

Pickup feeder modification kit

Column body

- Useful when the component pickup position is unstable due to large pocket size

- Stabilizes component orientation during component pickup

Media

Media

Column subtitle

Dust reduction HEPA filter

Column body

- Prevents dust and dirt from entering machine

Reduces mounting defects and ensures quality - Especially useful in improving mounting misalignment and missing components

- Also limits machine problems caused by dust adhesion on the inside of nozzles and sliding parts

Media

Media

Column subtitle

Soft tray pallets with flanges

Column body

- Prevents tray lifting and deformation when using soft trays

- Limits pickup mistakes and stabilizes component orientation

Media

Media

Column subtitle

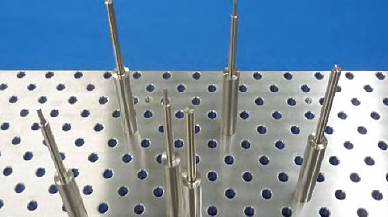

PCB support pins for small spaces

Column body

- Allows for flexible arrangements in accordance with space

- Limits PCB warpage and mounts components flatly

Media

Media

Column subtitle

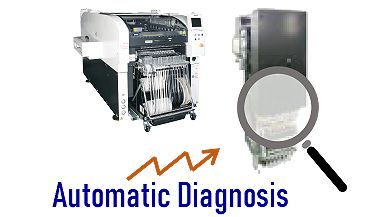

NPM head diagnosis

Column body

- Mounting machine performs automatic head diagnosis by itself

- Enables preventive maintenance through trend management

- Reduces the impact of head performance degradation on mounting quality

Media

Media

Column subtitle

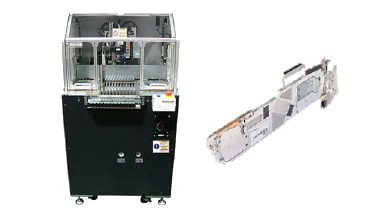

Feeder maintenance unit

Column body

- Provides automatic inspection, adjustment, and calibration of malfunctioning feeders

- Enables stable mounting thanks to the ability to monitor feeder status

- Reduces man-hours through automation and the need for skilled workers

Media

Media

Column subtitle

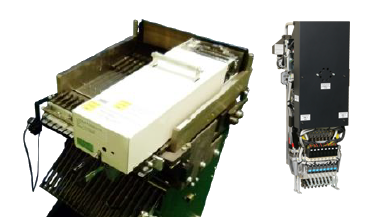

Head maintenance unit

Column body

- Automatic nozzle holder attachment and detachment, cleaning, and inspection

- Routine maintenance of placement heads can be performed without the need for skilled workers

- Reduces man-hours due to short work time

Media

Media

Column subtitle

Nozzle cleaning tool

Column body

- Quick and reliable cleaning of nozzles

- No knowledge nor high investment required

- Small size enables installation and storage anywhere

Media

Media

Column subtitle

Nozzle storage case

Column body

- Protects against scratches and damage caused by nozzle collisions

- Damage to nozzles can lead directly to machine problems, and the expansion and contraction membrane guards against such damage

Media

Media

Background colour

Grey

Section intro title

Inquiries

Wysiwyg body

Campaign description

Support Items to Improve Quality

Proposals by Problems and Solutions

Proposals by Problems and Solutions

URL alias

/products-services_fa/solutions/problem/quality/item

Use WYSIWYG header

On

Campaign header WYSIWYG

Support Items to Improve Quality

Proposals by Problems and Solutions

Automate carousel?

Off

Display in-page navigation

Off