As PCBs become more diverse, each industry demands a variety of component mounting needs, such as thin and large PCBs, and small component and high-density mounting.Panasonic offers solutions that support various PCBs, as well as solutions that achieve high quality and productivity.

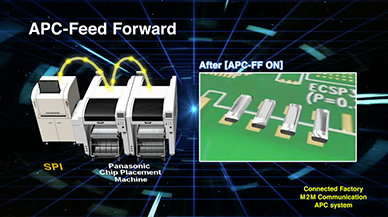

APC System (APC-FF/APC-MFB2)

The placement position is corrected in cooperation with other companies' inspection equipment to maintain mounting quality for printing and mounting displacement caused by PCB expansion and contraction.

Manufacturing Operation Optimizer MFO

Resource information such as production conditions, number of workers, and multiple line configurations, as well as production performance information, are reflected in the production plan created by the production scheduler. Automatically generates production planning and implementation programs with less changeover and high production efficiency.

その他のソリューションについては、ダウンロード資料をご覧ください。

各機能に対応可能な製品について詳しくは当社までお問合せください。

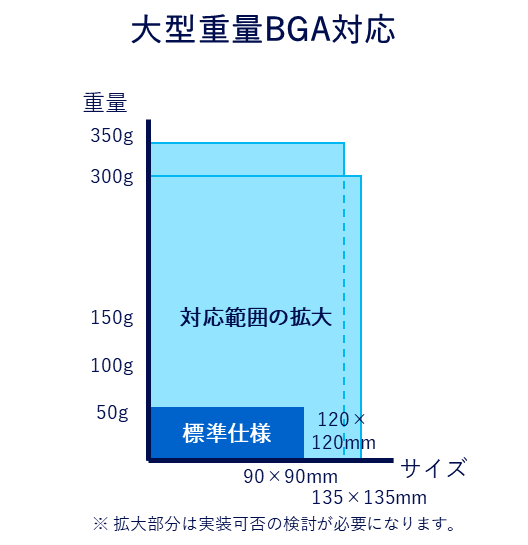

大型部品対応

BGAのサイズと重量の大型化が進んでいます。パナソニックでは最大サイズで□135㎜・300gまで対応しています。

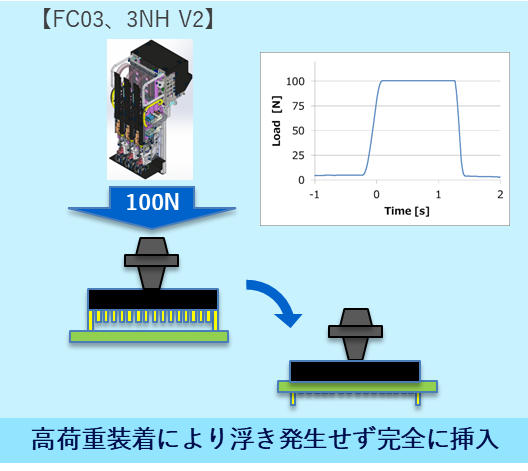

最大100Nの荷重実装

100N荷重実装により、多ピンのコネクターを手挿入工程から実装機による自動化を実現し、実装品質を向上させます。

Top/Side Clamper

In addition to the conventional side clamper, a top clamper is adopted to hold the PCB from the top. This strengthens the solution to PCB warpage and further improves print quality.

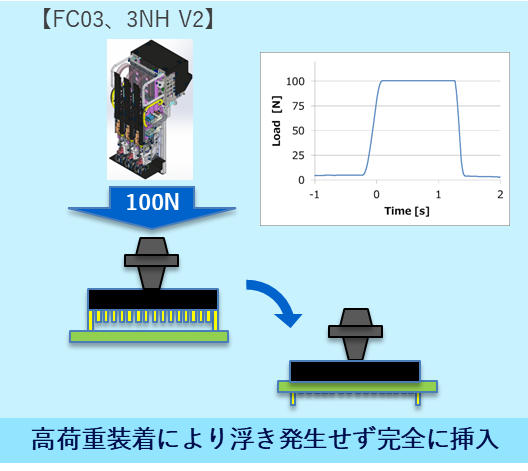

最大100Nの荷重実装

100N荷重実装により、多ピンのコネクターを手挿入工程から実装機による自動化を実現し、実装品質を向上させます。

その他のソリューションについては、ダウンロード資料をご覧ください。

各機能に対応可能な製品について詳しくは当社までお問合せください。

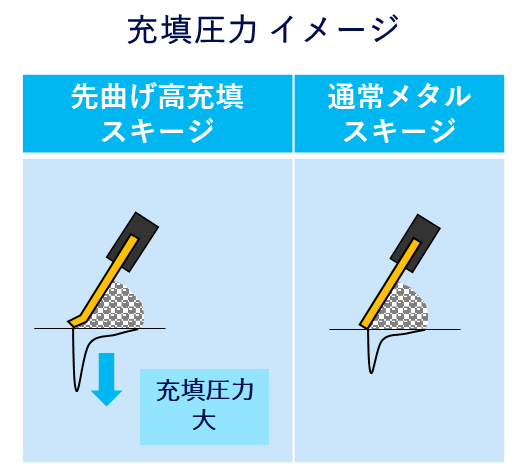

先曲げ高充填スキージ

微小部品と大型部品が混載される基板へのクリームはんだ印刷では、メタルマスクの開口通りの体積確保が重要です。先曲げ高充填スキージは、先端の曲がっている部分で充填圧力を高め、体積率を向上させると共にばらつきも抑制できます。

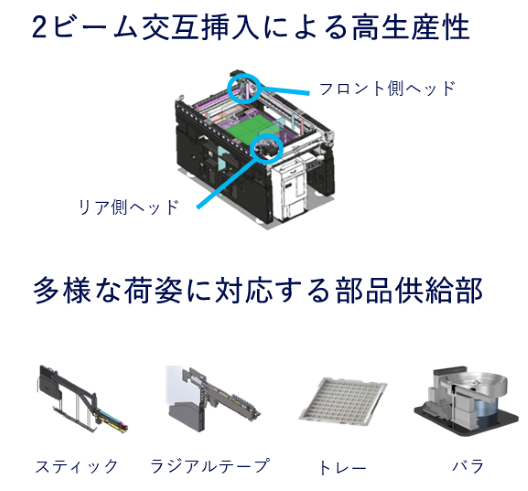

挿入機 NPM-VF

NPM-VFは異形部品・大型部品の挿入・装着をインラインで行なう事ができます。ヘッド構成2ビームにより、最高タクト0.65秒の高生産性を実現します。

Height sensor

The entire PCB height (warpage) can be measured, the mounting height can be corrected, and placement can be performed. If the measurement result exceeds the allowable value, a warning is issued before starting placement.

General-purpose cell line

This line eliminates balance loss in the production of multiple models with different placement points on the front and back of the PCB, and achieves high-efficiency operation. For example, utilizing dual lanes, balance loss is eliminated by optimal allocation of the number of heads even when there is a difference in the number of placement points on the front and back of a mixed flow line.

その他のソリューションについては、ダウンロード資料をご覧ください。

各機能に対応可能な製品について詳しくは当社までお問合せください。

For other solutions, please see the downloadable documents. Please contact us for more information on products compatible with each function.

Download

Screen Printer

NPM-GP/L

Optimizes the screen printing process. Equipped with automation functions, also capable of high-accuracy screen printing.

Modular Placement Machine

NPM-GH

This edge device achieves industry-leading productivity and mounting quality for Autonomous Factory. Proposes control of irregularities in the 5Ms and elimination of skill-dependent work.

Modular Placement Machine

NPM-GW

The basic performance has been improved by renewing the core units, such as the mounting head and recognition camera. It now supports a wide range of parts and PCBs.

Manufacturing Operations Optimizer

MFO

The “Next Innovation" in mounting production lines.

Automatic planning of optimal production based on collected worksite information, parameters, and mounting PCB data

APC System

Connecting a mounting machine or printers to inspection equipment enables components to be placed correctly in the target position