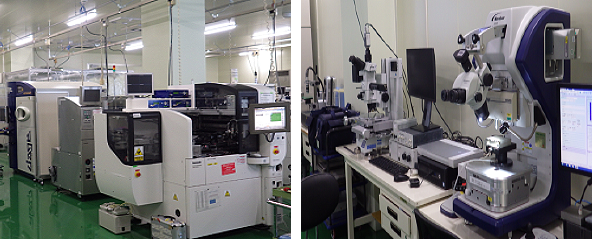

The Kadoma site has a plasma dicing demonstration center, a dry etching demonstration area, and a plasma cleaning demonstration area.

We have the necessary devices for evaluation, and inspection devices for demonstration to obtain accurate results, and we accept demonstration requests from customers.

Kadoma site [Plasma dicing demonstration center]

Support details:

Demonstrations of plasma dicing for silicon wafers with a diameter of 200 mm or 300 mm

(Wafers with a size of 200 mm or less are also supported)

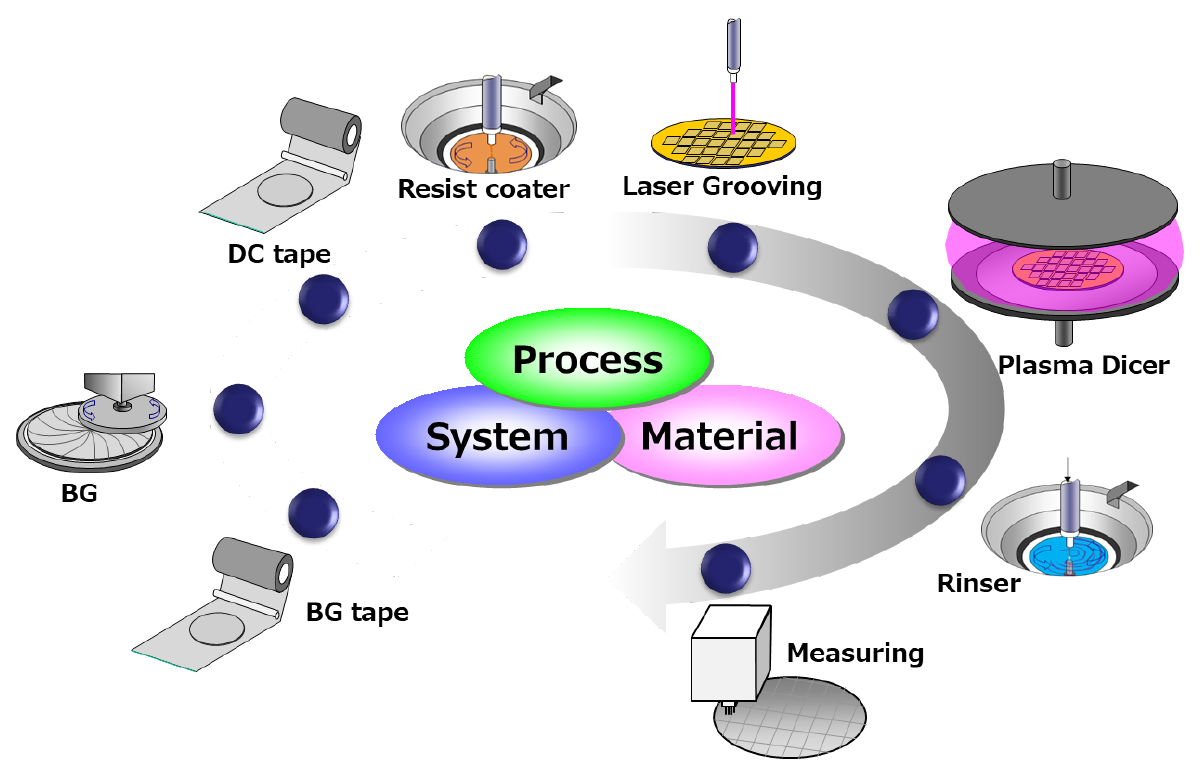

Main devices:

- Plasma Dicer APX300-DM

- Peripheral processing devices

- Back grinder:

Thins wafers to a specified thickness - Lithography:

Applies a protective layer of plasma irradiation to the wafer to determine the dicing position - Laser patterning:

Forms dicing lines

- Back grinder:

- Inspection devices

Measurement of processing steps and film thickness, electron microscopy, etc.

We have all the necessary devices for processes before and after plasma dicing to provide a one-stop demonstration service.

Kadoma site [Plasma cleaning demonstration area]

Support details:

Effectiveness of plasma cleaning PCBs and wafers

Main devices:

- Plasma Cleaner PSX307S, PSX307M, PSX307A

- Inspection devices

Water droplet contact angle measurement, surface elemental analysis, film thickness measurement, electron microscopy, etc.

Minoshima site [Die and flip-chip bonding demonstration area]

Support details:

Die bonding and flip-chip demonstrations

Main devices:

- Die Bonder MD-P200DA

- Flip Chip Bonder MD-P200US2, MD-P300

- Inspection devices

Transmission X-ray device, die shear tester, metallographic microscope, etc.

2-7 Matsubacho, Kadoma City, Osaka 571-0056

4-1-62 Minoshima, Hakata-ku, Fukuoka City, Fukuoka 812-8531

For details, please contact one of our sales companies or sales representative.

Alternatively, please use the Inquiry Form at the bottom of this page to contact us.

![Kadoma site [Dry etching demonstration area]](/sites/default/files/2022-03/fa-campaign-showroom-kadoma-04.png)