Please contact us with any problem that you are facing, from products to entire lines and floors. We will offer proposals to meet your needs.

Online verifications and demonstrations are available at the Fukuoka Technical Center.

Please take advantage of this service.

Organization name and position are at the time of filming.

Proposal of highly functional and efficient production using a production line that imitates the customer’s production site

1. Device/smartphone line

- Micro component mounting (0201 components onward)

- Densified mounting

- High-quality manufacturing (M2M link system)

- Improved productivity (automatic changeover using iLNB)

2. Automotive/industrial device line

- Large/tall component mounting

- High-quality manufacturing (M2M link system)

- Improved productivity (automatic changeover using iLNB)

- Traceability

Our staff will work with you to solve problems (printing to reflow, mounting analysis, and production technical support)

- Verification and demonstration using demonstration/customer PCBs, components, and bonding materials

(Printing, pickup, recognition, placement, reflow, and bonding quality) - Optimization of printing conditions

- Optimization of pickup and placement conditions

- Takt verification

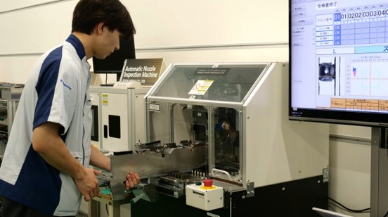

- Automation and labor-saving

- Void observation using an X-ray inspection device

- Confirmation of printing accuracy, solder volume, and solder shape of printed solder by inspection machine. And evaluation of normal distribution.

- Various seminars on mounting methods, printing methods, etc.

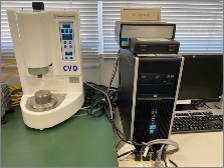

Various equipments are available for visualization of solder/component conditions and changes in printing, mounting, and joining.

[Printing] Spiral solder viscometer

[Printing] Micro spiral viscometer

[Printing] Solder agitator

[Printing] Rheometer

[Printing] Mask tension gauge

[Printing] Shape analysis laser microscope

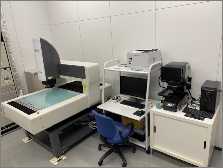

[Mounting] High-precision image measurement system

[Mounting] Mounting accuracy and load measuring instrument

[Printing/Mounting] High-speed microscope

[Printing/Mounting] High-definition 3D printer

[Joining] Reflow simulator

[Joining] Automatic grinder with individual loading method

Digital microscope

3D Shape measuring machine

Laser elemental analyzer

Online verifications and demonstrations

Online verifications and demonstrations that use the Internet are provided. Although you cannot touch the actual machines, you can communicate interactively with us by asking and answering questions, so you can understand more about the product than simply looking at a catalog or video. It is also possible to connect to multiple locations at the same time from within the company. It is easy to participate even from afar and less time consuming, so please take advantage of this service!

The center reproduces the SMT site in the image of the customer's SMT floor, with not only our products but also machines and devices from alliance partners. We offer concrete proposals to solve problems in each area.

In this area, aiming for intelligent human decision making, visualization of the mounting floor and resource-aware production simulation of the entire mounting area directs efficient production execution. Also, solutions for manpower saving, such as remote operation, are introduced.

In this area, in addition to checking actual equipment when selecting equipment, Panasonic mounting equipment, inspection machines, and reflow furnaces are also connected to the line, allowing production verification using actual materials. In addition, automation functions aimed at automating human work are introduced.

This area manages the receiving and shipping of materials needed for production and performs picking operations based on instructions from the materials management system.

In this area, the picked parts are linked to the production plan and set on the feeder/bulk change carts according to the navigation system instructions.

In this area, we introduce automatic maintenance equipment for mounting heads, nozzles, and feeders, which are the key to producing good products. We propose the construction of a system for manufacturing with good heads, good feeders, and good nozzles.

A variety of products is always on display in this area. We provide total system solutions by combining the most appropriate solutions and products while listening to your needs.

- PCB: Demonstration PCB (devices, smartphones, vehicles, and computers)

- Component: 0201 to large odd-form components for vehicles

- Bonding materials: Solder and adhesive

- Other: Various idea products, etc.

We introduce a variety of useful functions in a layout that is reminiscent of a customer’s production factory (manufacturing area).

| Printers | Screen Printer NPM-GPL |

Screen Printer SPV-DC |

Screen Printer SPG2 |

|---|

| Solder inspection devices | Koh Young(Meister S:5um) CKD (VP6000LD-V: 15 μm, VP6000M-V: 8 μm) PARMI (SIGMAX: 5 μm) |

|---|---|

| Component visual inspection devices | SAKI(3Di-LD3:8μm) PARMI(Xceed:7μm) |

| X-ray inspection devices | OMRON (VT-X750: CT type, 6 μm variable) |

| Reflow oven | Senju Metal (SNR-840GT) |

| Other | Malcom (High-temperature Observation Oven) Nikon (NEXIV Video Measuring Systems) Keyence (Various microscopes) |

4-1-62 Minoshima, Hakata-ku, Fukuoka City, Fukuoka 812-8531