Compared to semi-automatic welding, TIG welding requires more skill because changes in the distance between the tungsten tip and base metal have a significant impact on welding results (bead width and penetration). In addition, ensuring welding quality has become an issue at many worksites in recent years due to a decrease in the number of skilled personnel.

■Bead width is not stable.

■Burn-through occurs frequently.

■Difficult to recruit welding personnel.

Welding method: DC TIG welding (Welding power source: 300BZ3)

Base metal: SUS304, Plate thickness: 2.0 mm

Pulse current: 90 A/20 A, Pulse frequency: 3 Hz, Pulse width: 50%

・Robots can perform high-quality, uniform and stable welding without the shaking that occurs with human hands. High-speed welding is also possible by optimizing conditions.

・High-speed welding is also possible by optimizing conditions.

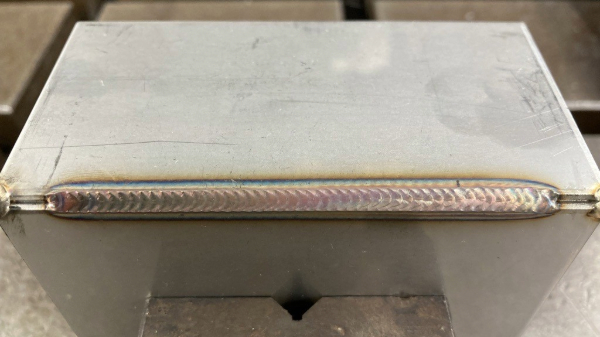

Welding method: Robot DC TIG welding (Welding power source: 300BZ3) Base metal: SUS304, Plate thickness: 2.0 mm, Welding speed: 0.3 m/min Pulse current: 90 A/20 A, Pulse frequency: 3 Hz, Pulse width: 50%

Welding Power Source Separate Robot "GIII"

High quality welding in combination with full digital welding

Panasonic has established a system to support customers all over the world. Customers expanding production from Japan to overseas factories can also use our equipment with peace of mind.

Website dedicated page for members of Panasonic Shoyokai. You can download the application form to join the membership website P-Web.