Welding speed can be improved significantly with the Super Active welding method.

■Need to reduce cycle time without changing welding appearance.

Welding method: MTS-CO2 (Standard)

Base metal: Mild steel, Plate thickness: 2.3 mm, Wire diameter: ϕ1.2 mm.

Welding current: 170 A, Welding speed: 50 cm/min

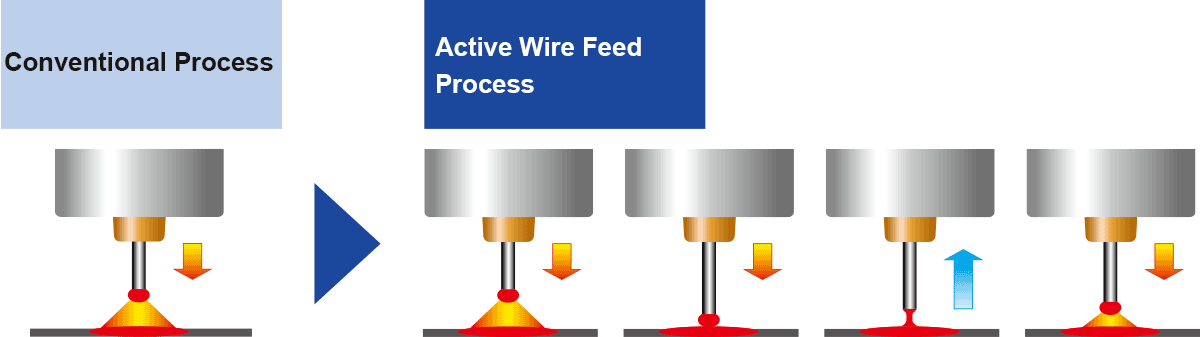

What is the Super Active Wire Feed Process?

High-precision feed control where the welding wire is fed continuously with a back and forth motion. Spatter reduction by stable short-arc cycle.

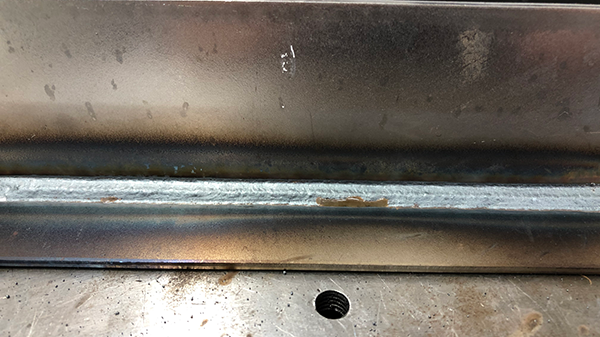

Bead is smooth even when welding speed is more than doubled.

Welding method: Super Active welding method (TAWERS CO2)

Base metal: Mild steel, Plate thickness: 2.3 mm, Wire diameter: ϕ1.2 mm.

Welding current: 300 A, Welding speed: 120 cm/min

Welding Power Source Integrated Robots "TAWERS"

The robot itself has direct full control of the welding waveform and can handle a variety of welding styles with the addition of applications.

We will also introduce various concrete examples of TAWERS.

Panasonic has established a system to support customers all over the world. Customers expanding production from Japan to overseas factories can also use our equipment with peace of mind.

Website dedicated page for members of Panasonic Shoyokai. You can download the application form to join the membership website P-Web.