Key features and functions

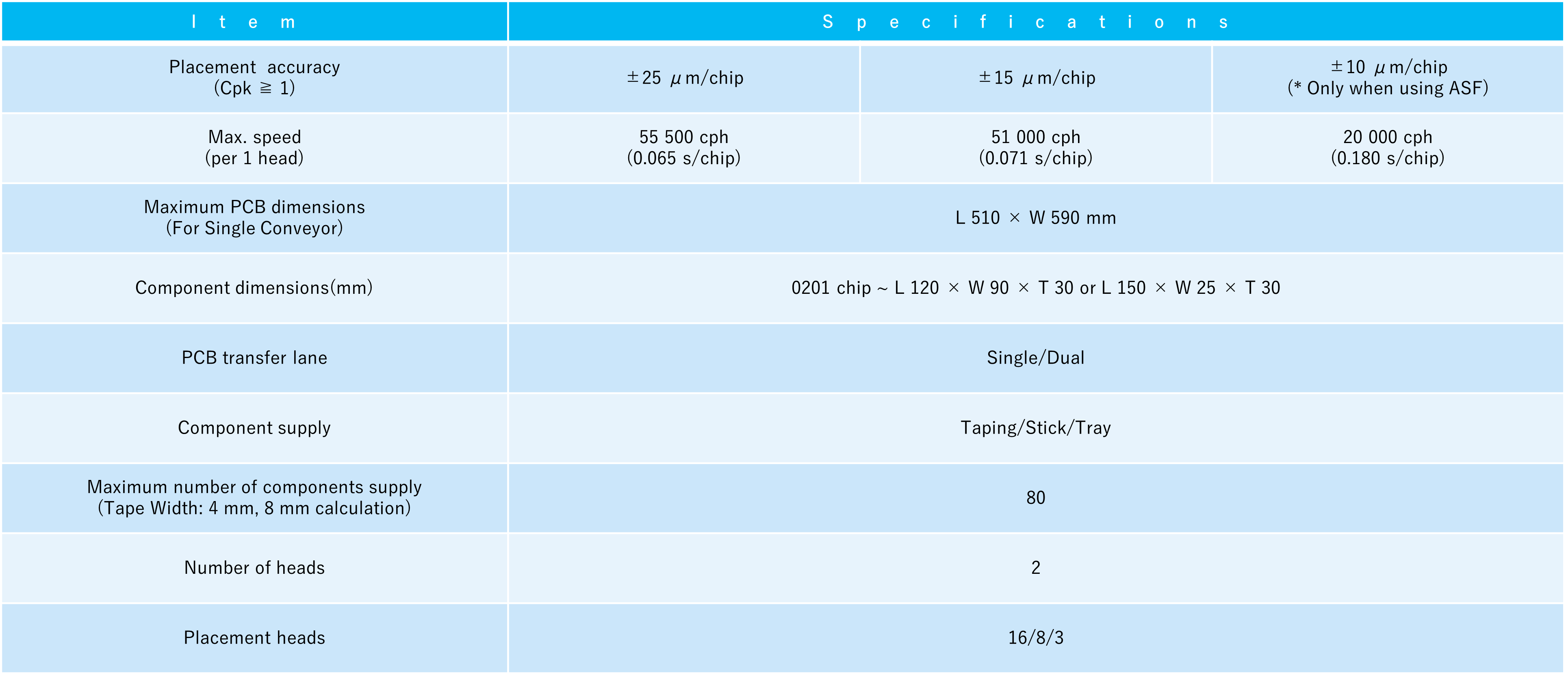

- High accuracy mounting ±10 μm for modular placement machine

- Achieves high productivity while supporting a wide range of components

- 5M process control “APC-5M” for good production and stable operation

- Various skill-less and manpower-saving features including Auto Setting Feeder

* 5M: The variable elements of a production site: huMan, Machine, Material, Method, and Measurement

This modular mounter achieves both high productivity and high accuracy by improving the basic performance of key units such as the placement head and recognition camera. It is compatible with a wide range of components and a variety of supply units layouts. It also supports a variety of automation and labor-saving functions, including the Auto Setting Feeder (ASF), which automates components supply work, to flexibly meet the demands of each mounting site.

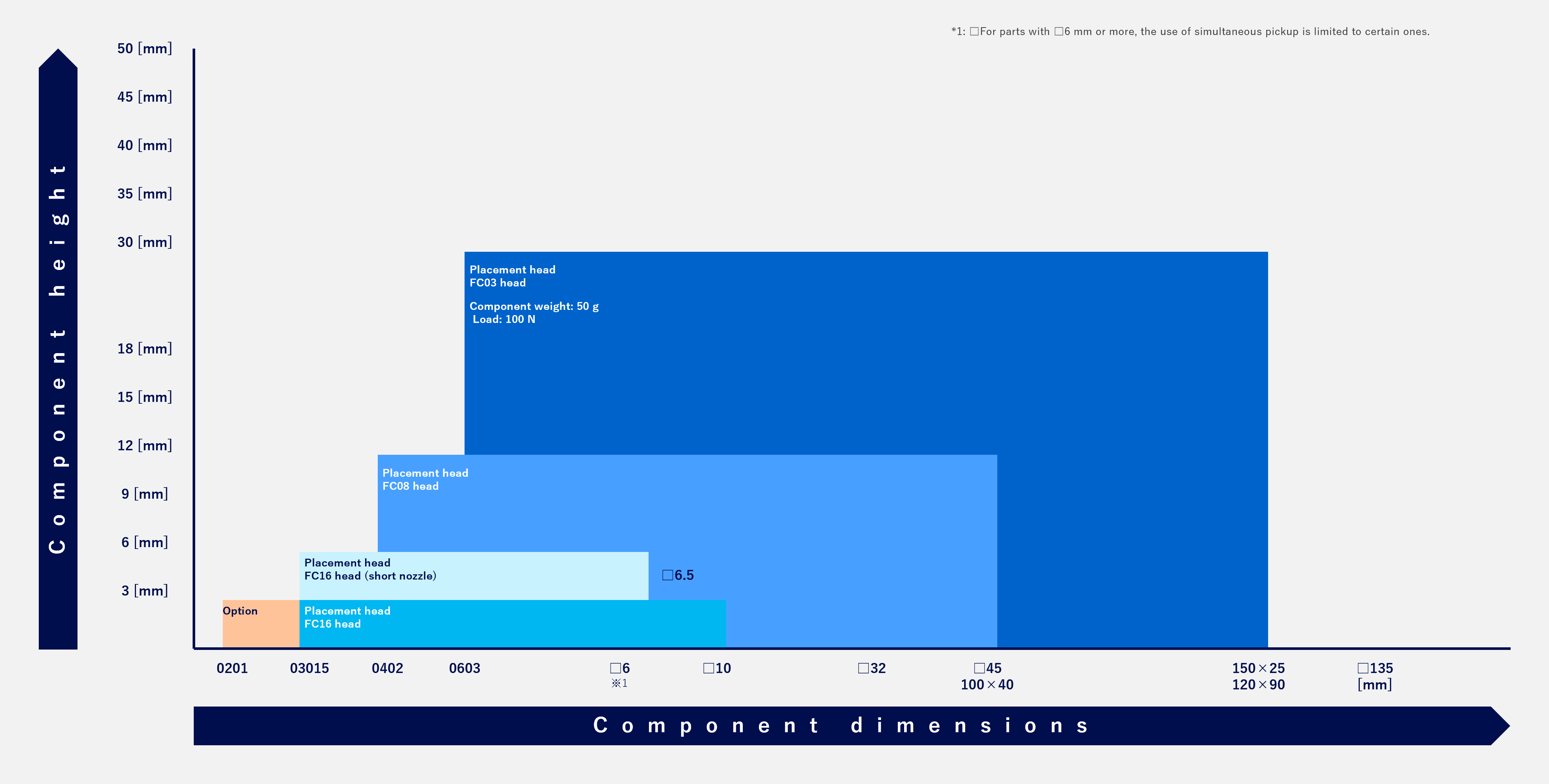

Support for a wide variety of components

Supporting wide variety of components, from micro to large.

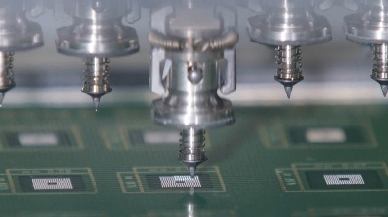

High quality mounting

Mounting with high quality even when small components and high-accuracy mounting are required such as in the device industry.

Maximize O.E.E by minimizing various losses

Minimizing various losses at production sites, maximizes O.E.E (Overall Equipment Effectiveness), and improves productivity.

Enhance skill-less and labor-saving

Reducing human-dependent work, which is one of the causes of loss and quality degradation, and reducing dependence on specific workers by making them skill-less.

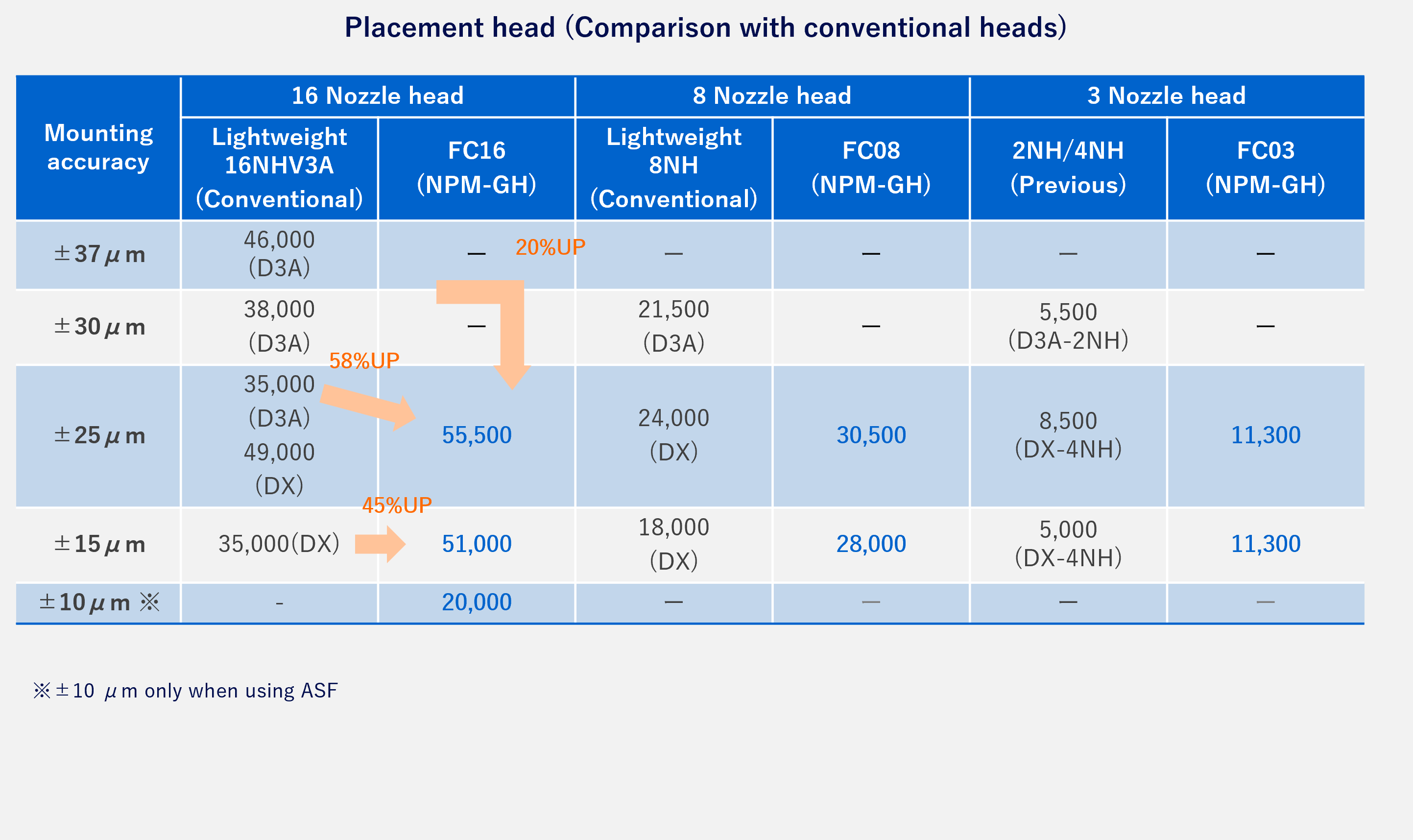

High accuracy mode 1 (± 15 μm)/2 (± 10 μm)

Supports mounting at ±10 μm *, the high level of accuracy as a modular placememt machine.When compared with catalog speed (CPH), ±25 μm is approximately 10% better than the conventional our NPM-WX.

※ASF (Auto Setting Feeder) is required for the FC16 head. Please contact us for details.

Placement head (new design)

Flexible head configuration for 0201 parts to large and tall components. Production can be performed with high productivity. When compared with the catalog speed (CPH), the NPM-GW is approximately 58% better than our conventional model at ±25μm condition.

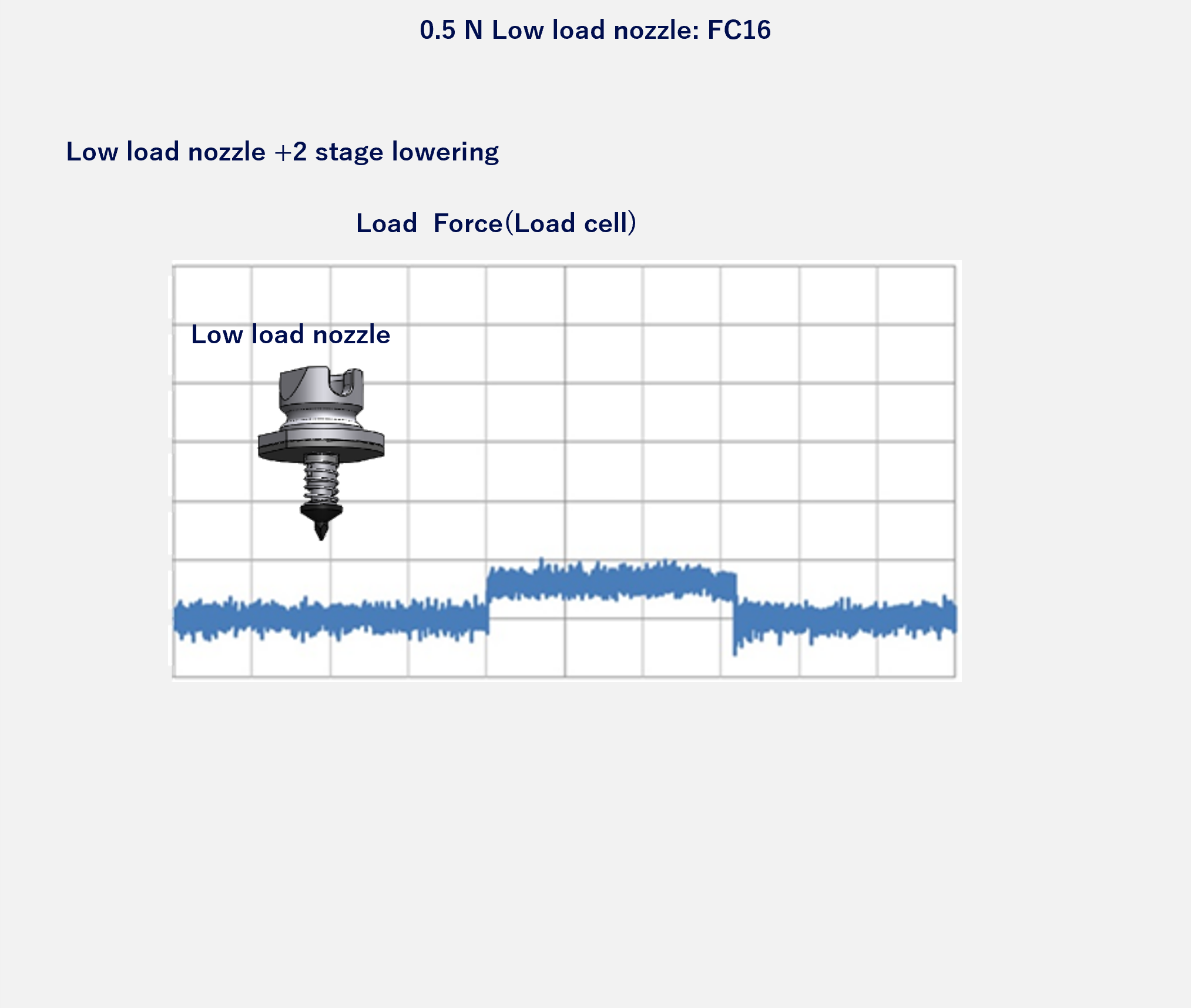

Low load mounting (1.0 N, 0.5 N)

Load applied to components is controlled on a components-by-components basis, load applied to mounting is controlled on a components-by-components basis, and damage to components can be reduced. In addition, mounting can be performed following warpage on the PCB. 1.0 N constant load control, 0.5 N constant load control, and 0.5 N low load nozzle enable optimum mounting of microcomponents.

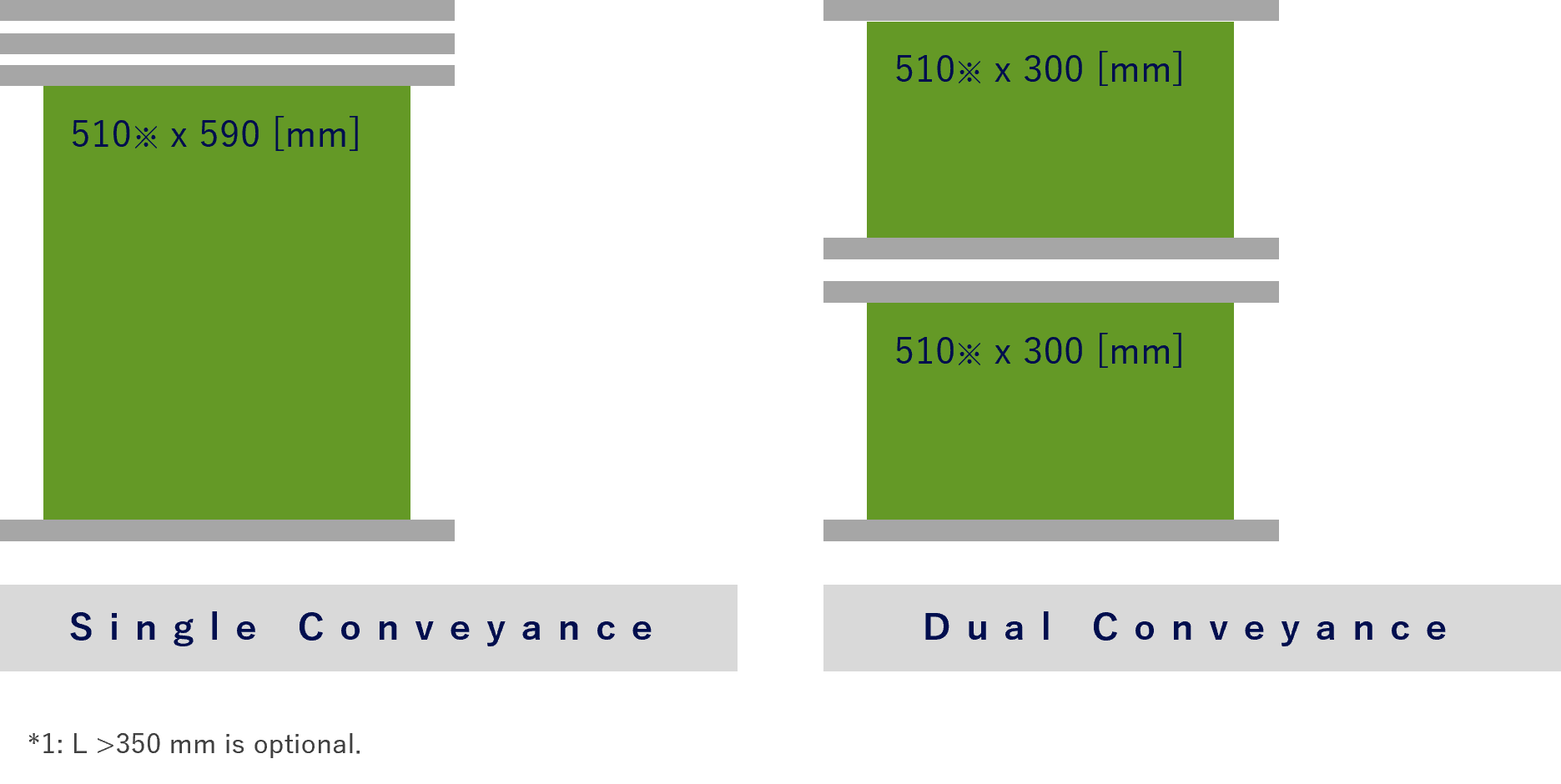

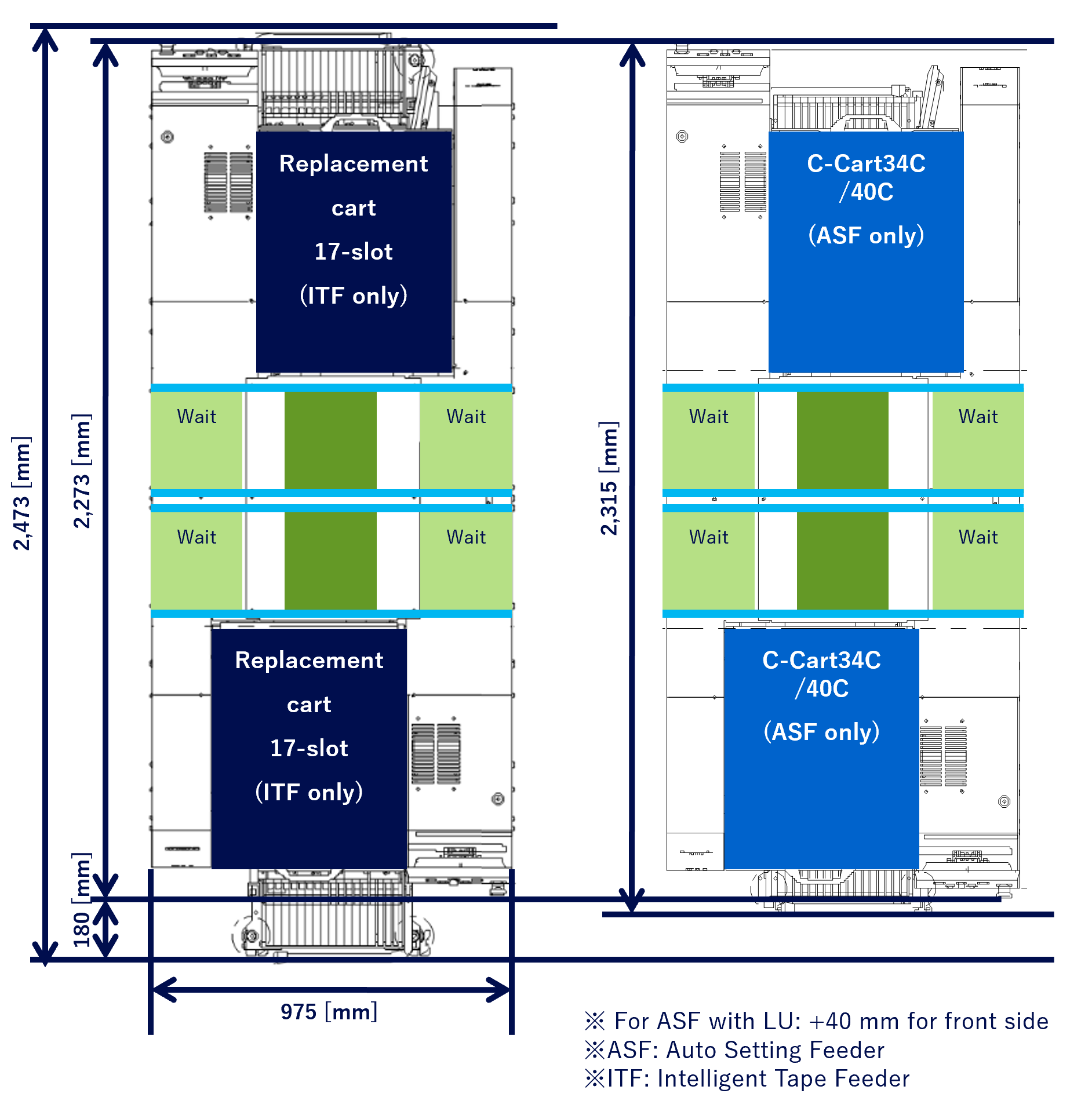

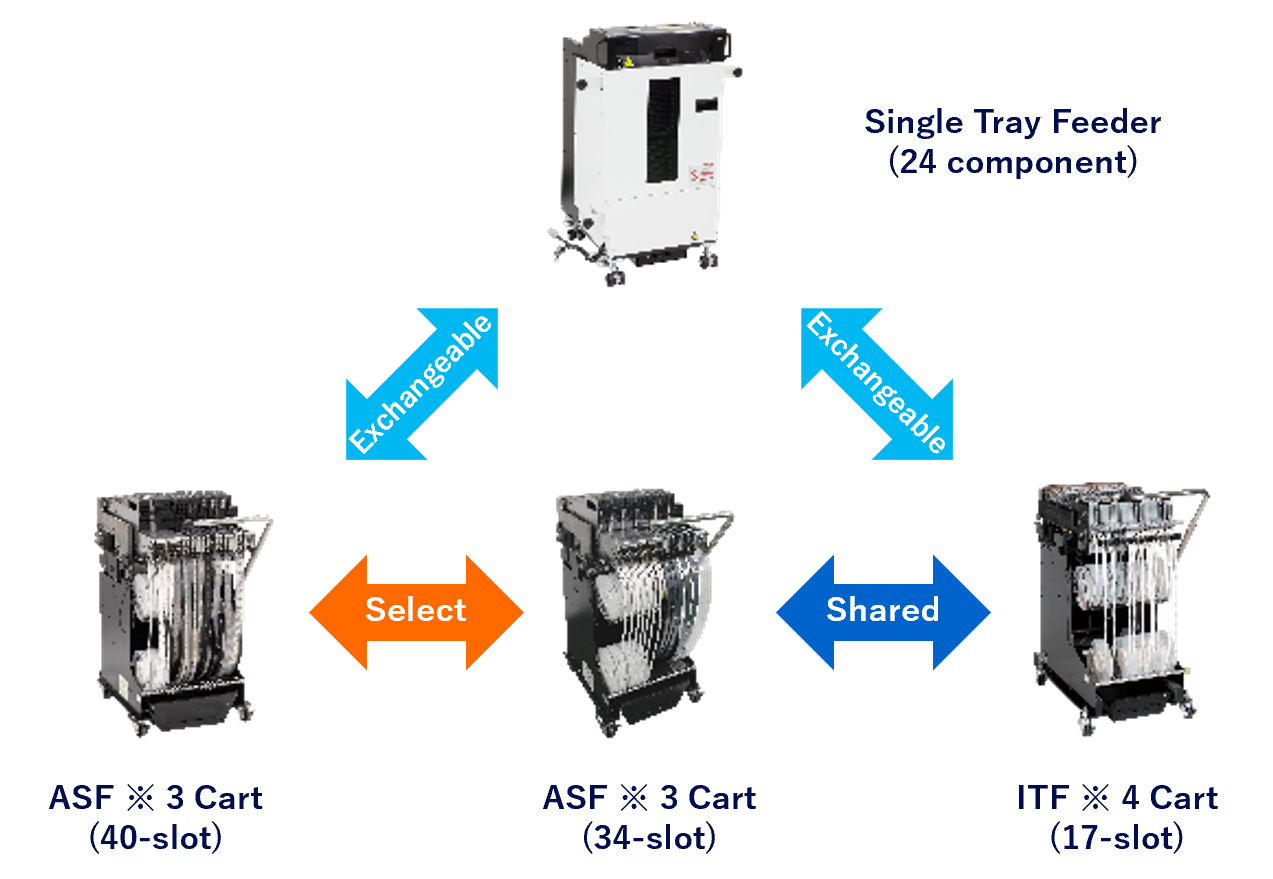

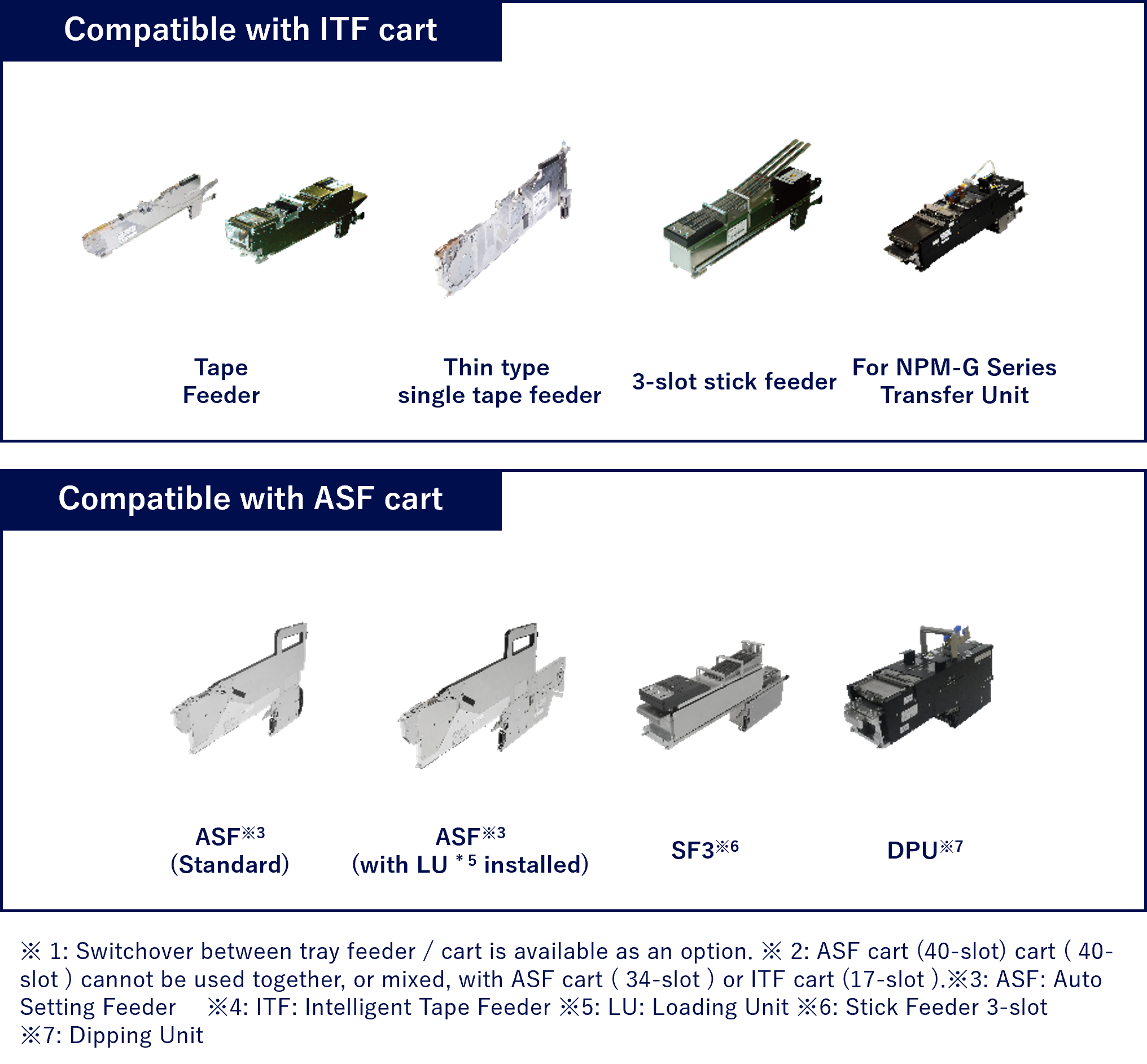

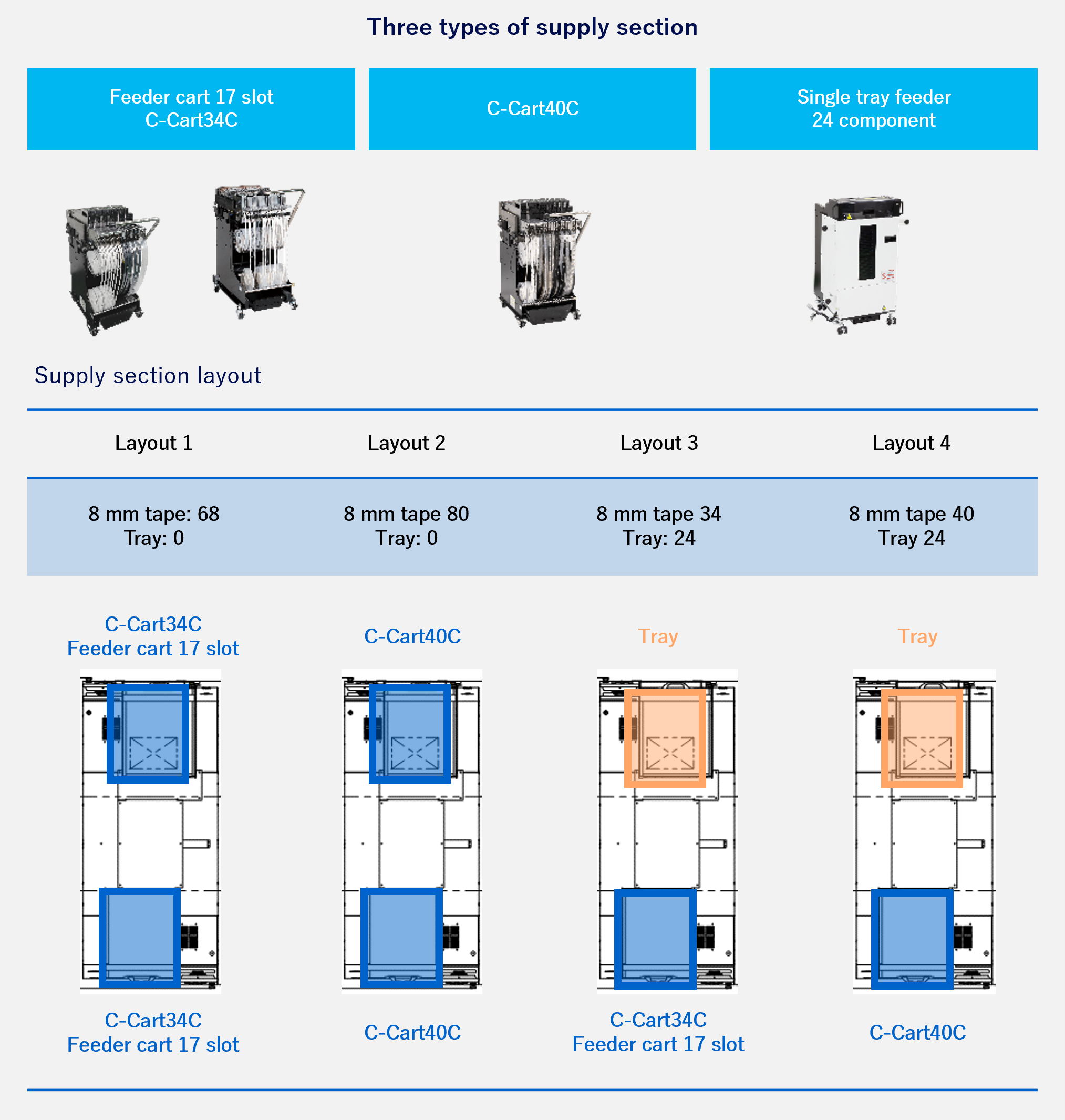

Three types of supply section units

By combining three types of supply section units, you can select a variety of supply section layouts.

※The single tray feeder can be used only in the supply section(rear side).

Component Thickness Measuring Function Multi Camera MC-S: Type 2/Type 3

The thickness of components is measured and the result is reflected in the mounting height to further improve mounting stability. Standing and oblique suction of minute components can be checked simultaneously. The nozzle tip check function periodically checks the nozzle height to improve mounting quality.

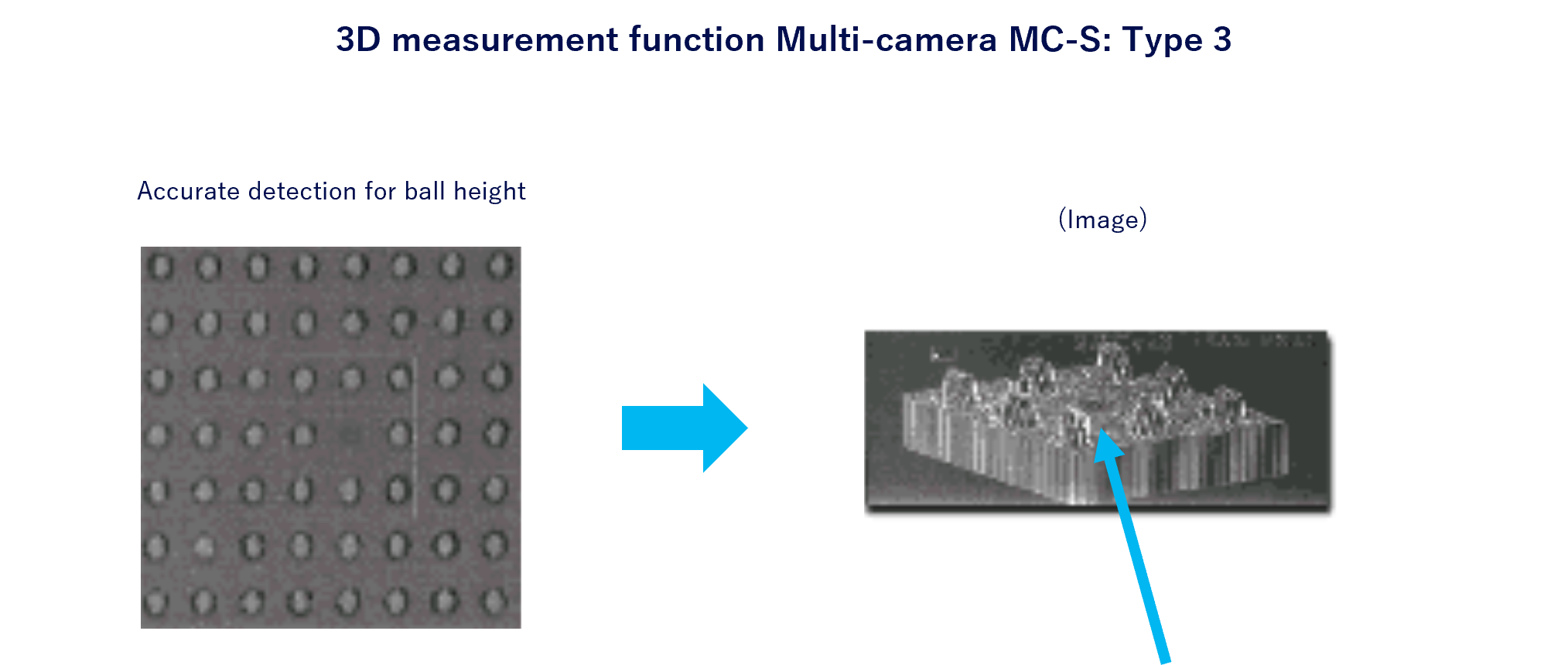

3D Measurement Function Multi Camera MC-S: Type 3

It is possible to detect coplanarity of all leads such as QFP/SOP and presence/absence of all balls such as BGA/CSP.

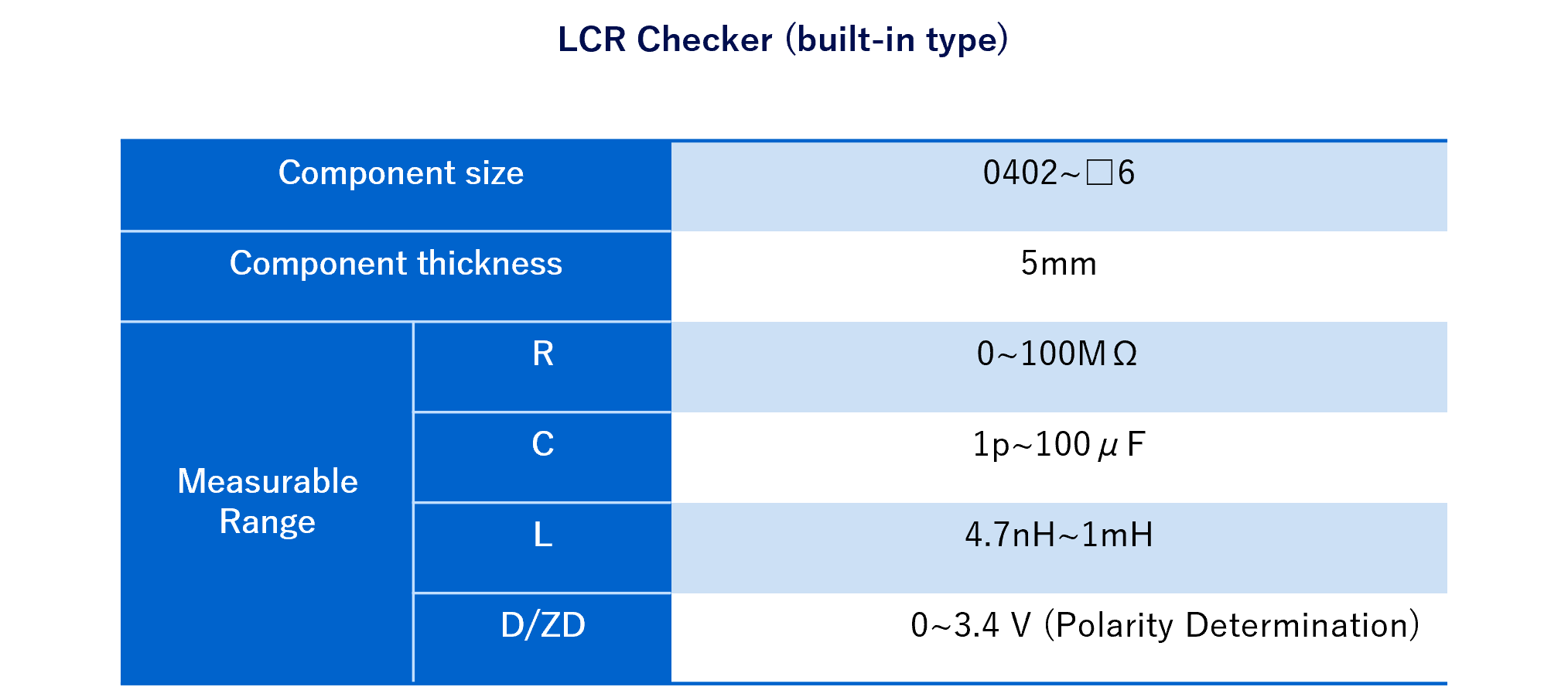

LCR checker (built-in type)

Prevents defective mounting due to mis-setting of parts by measuring the electrical characteristics of components . Stable measurement is possible due to stable maintenance of components attitude and position by the adhesive material. In addition, high-accuracy measurement is possible regardless of the nozzle used by measuring by pressing down the components with the metal lever.

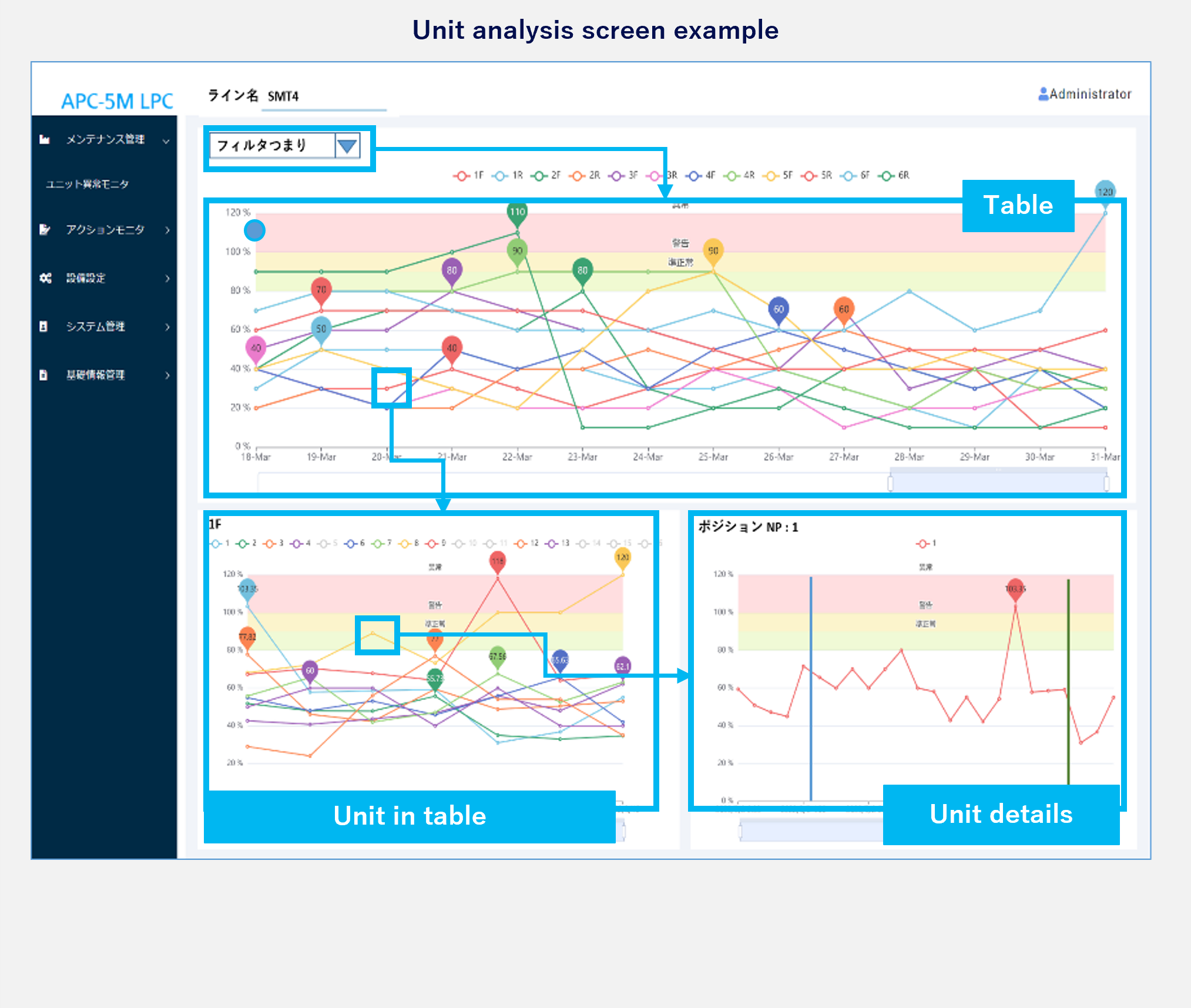

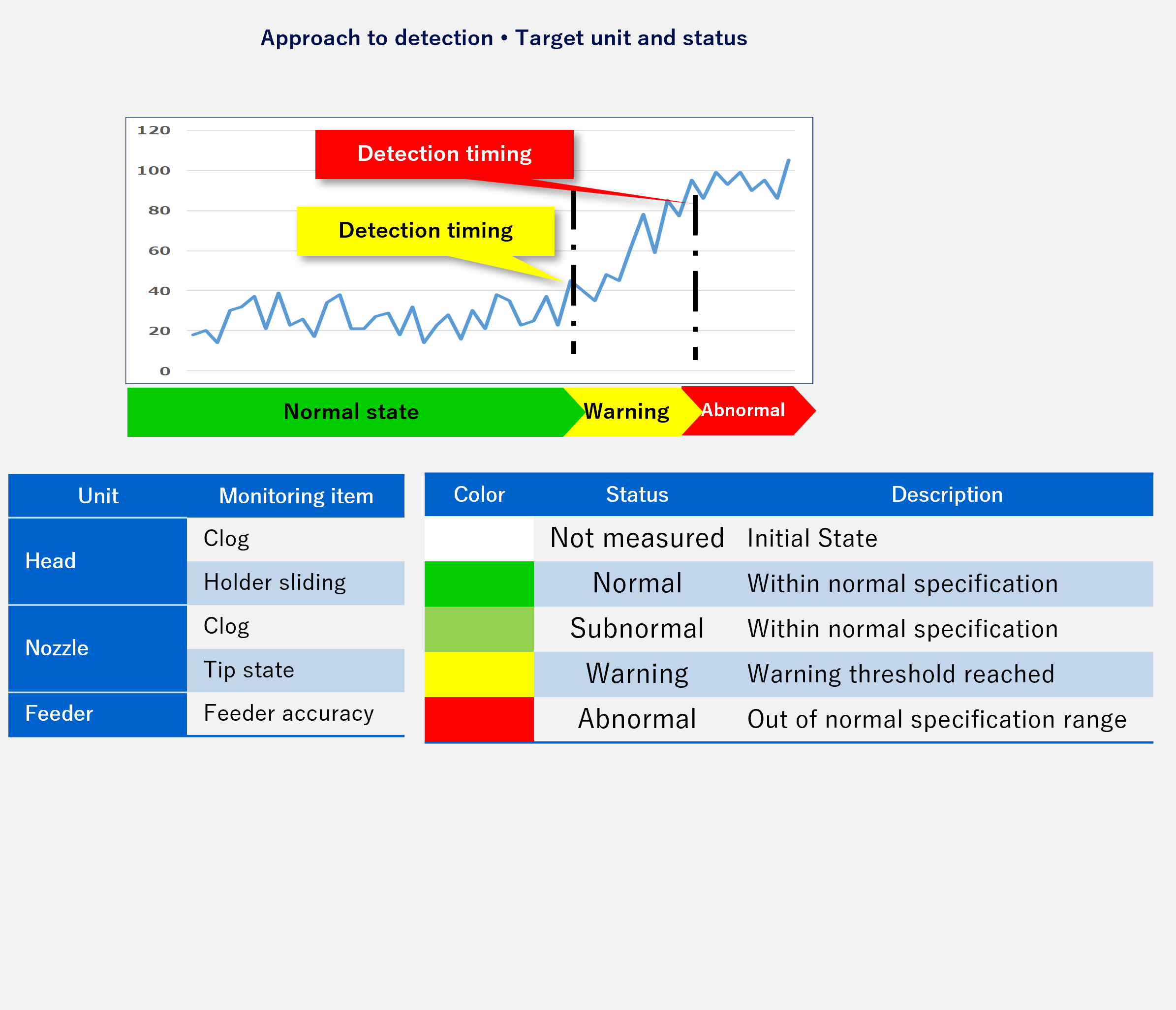

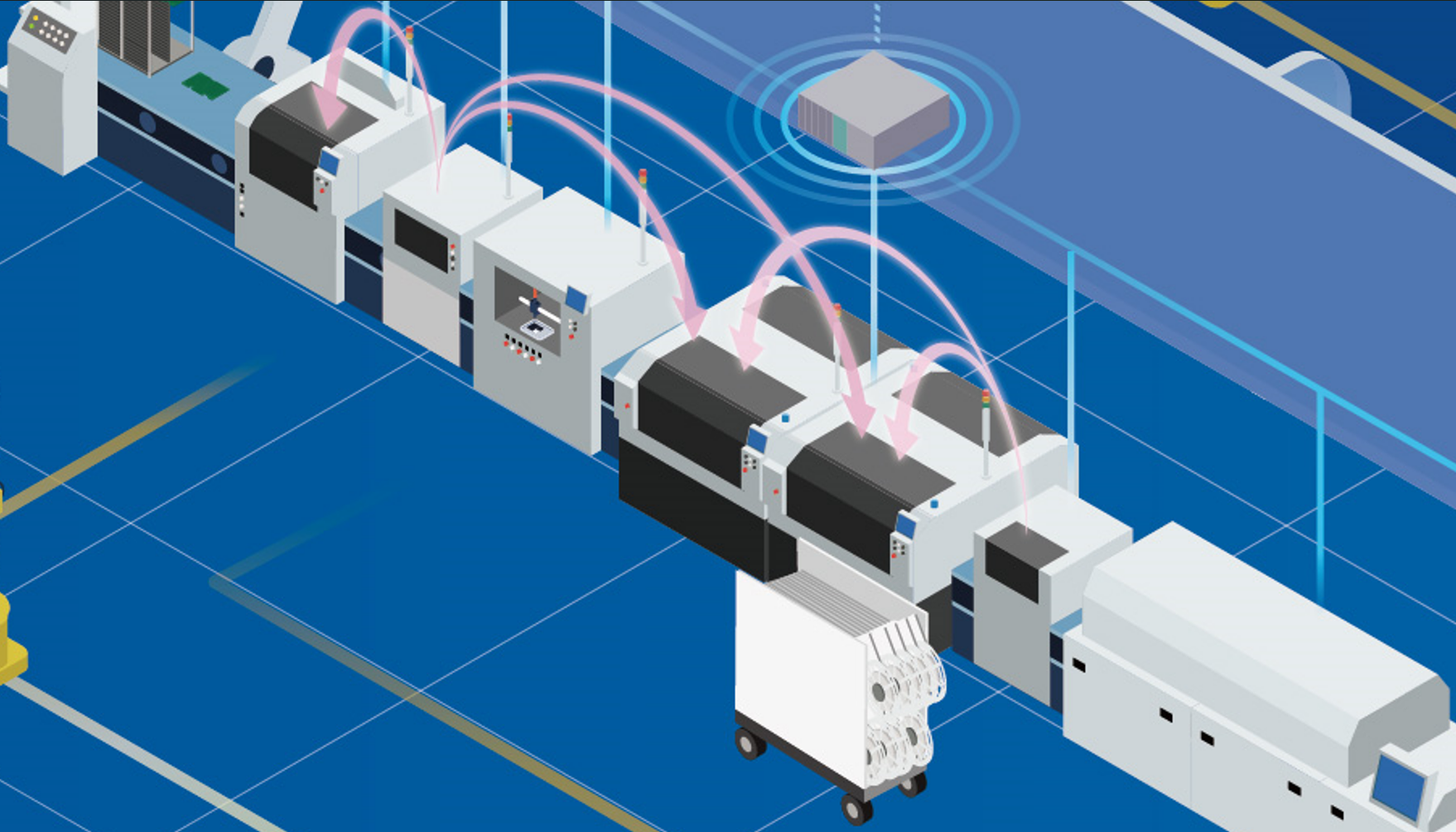

APC-5M (option)

To ontrol 5M variation autonomously, unit condition can be monitored, analyzed easily to ensure proper maintenance.

5M Unit conditions are monitored in real time to control variations autonomously, enabling predictive maintenance before conditions deteriorate and preventing errors due to lack of maintenance.

Not only showing the status of each equipment, but also the entire line can be displayed on the LPC (Line Process Controller) screen for line status monitoring, and the status of target units in the line can be broken down for time-series analysis. The status after maintenance can also be checked to determine if maintenance is appropriate.

※5M : huMan, Machine, Material, Method, Measurement

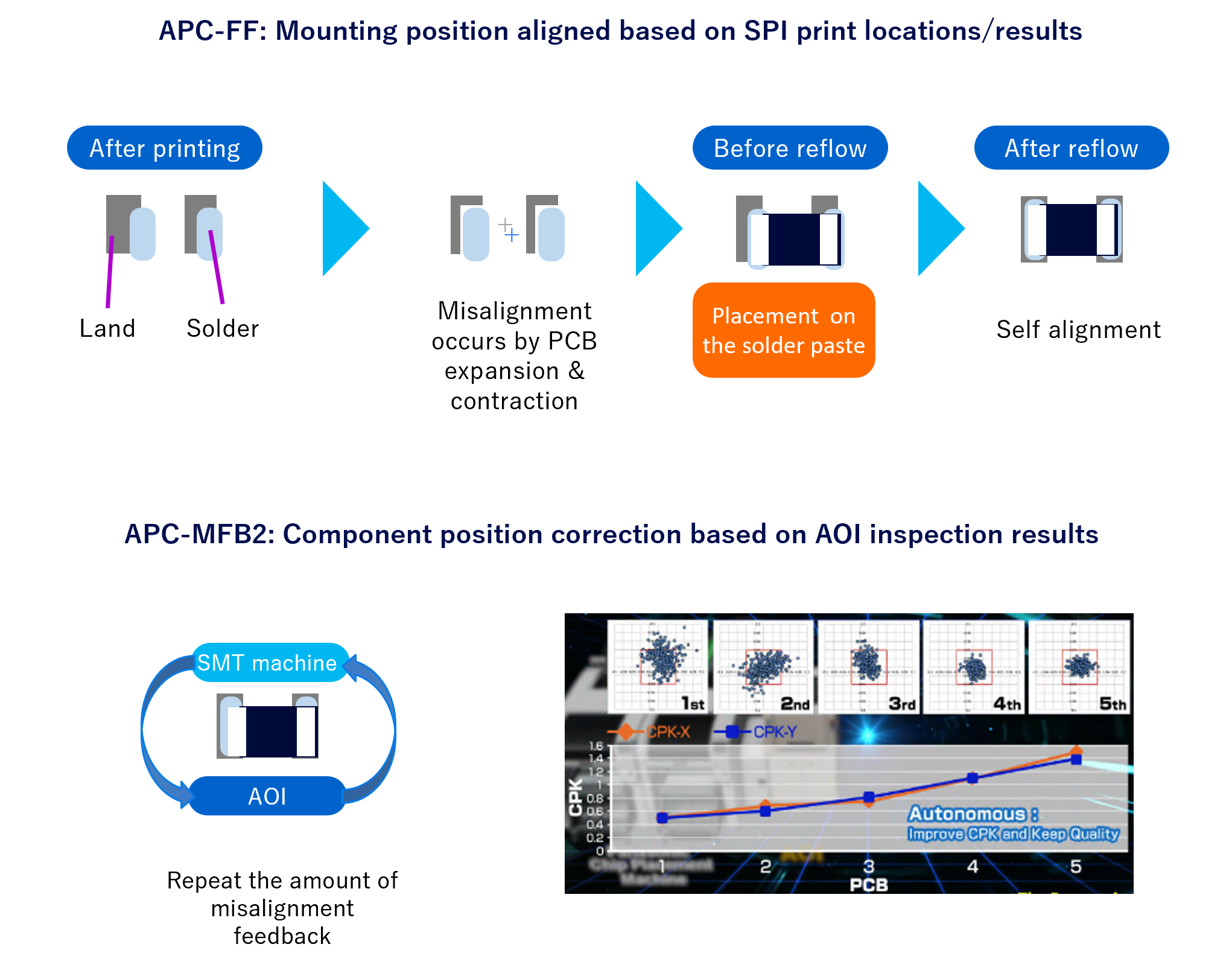

APC System (APC-FF/APC-MFB2)

Maintains mounting quality by controlling variation in solder printing and component placement in conjunction with the inspection machine.

APC-FF is our unique in-line process control system that feeds forward the mounting position correction amount to the mounting machine based on the solder position data measured by solder inspection to maintain mounting quality.

The APC-MFB2 maintains mounting quality by feeding back component position data measured by the inspection machine (AOI) to the mounting machine after component placement.

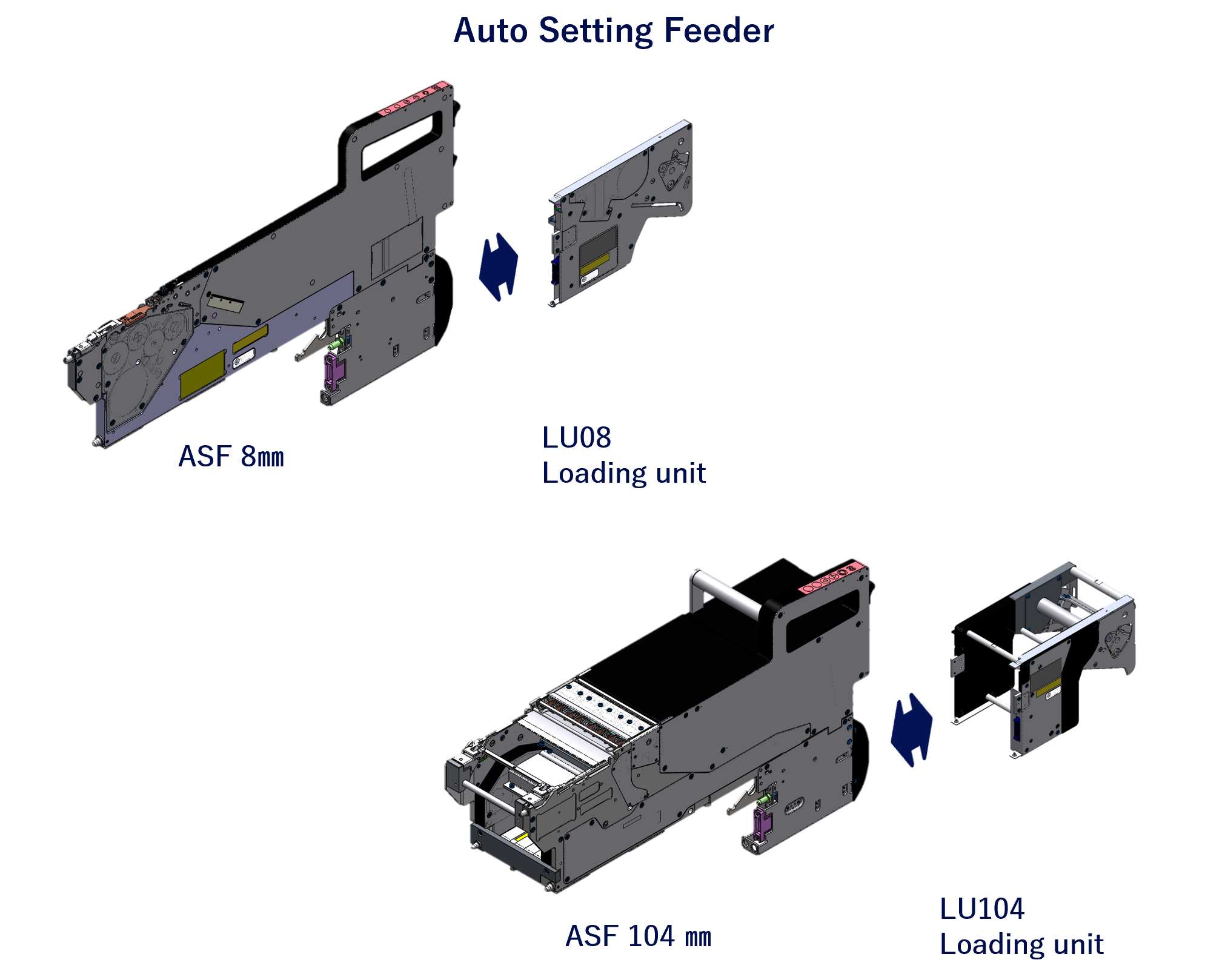

Auto Setting Feeder

Automated supply of 8 to 104 mm wide reels of paper and embossed tape. The loading unit can be used to automate not only new tape supply, but also the next tape supply.

Automatic setting reduces set-up time and skill, while automatic loading eliminates the work for splicing, realize skill-less work.

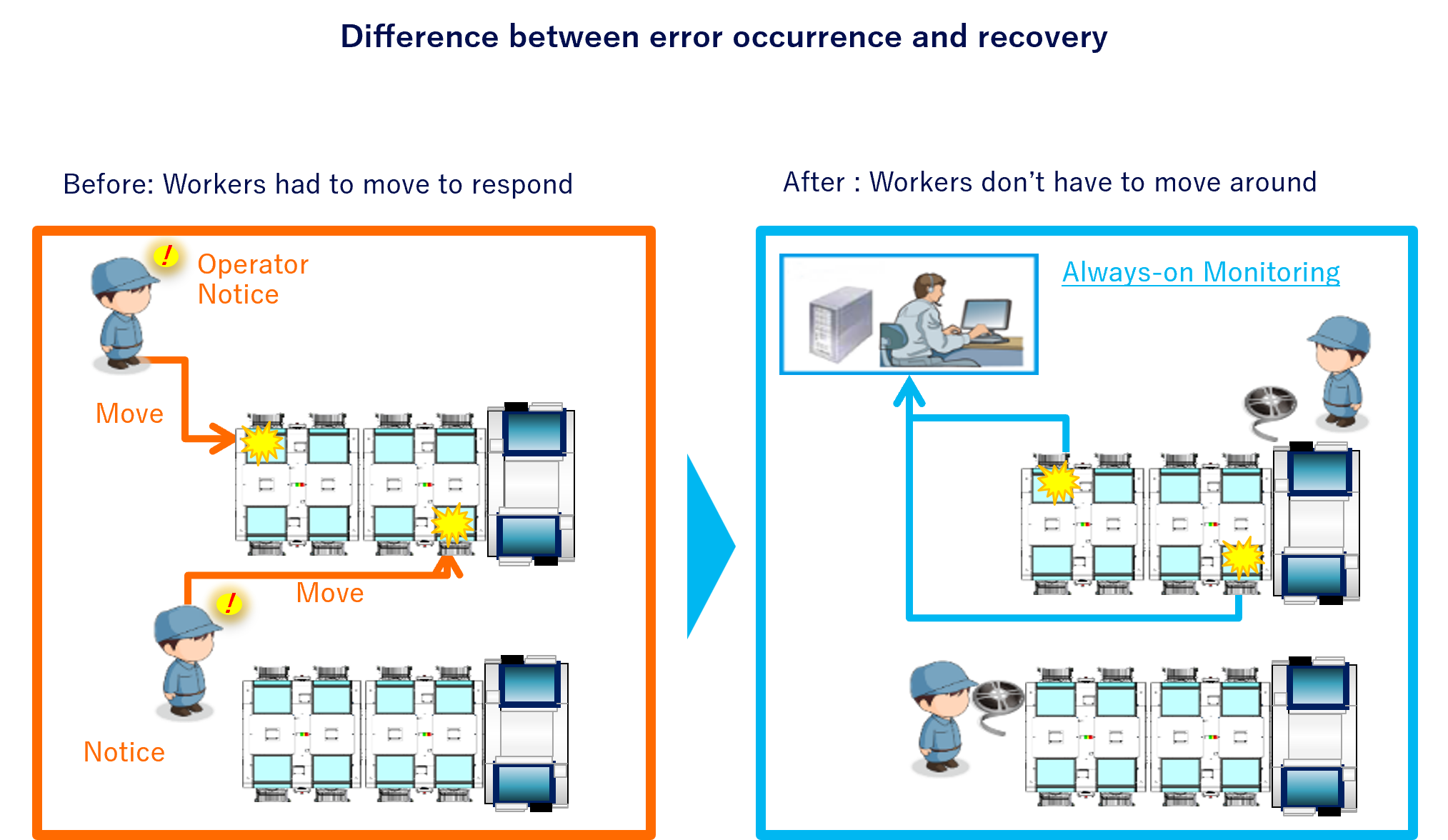

Remote Operation

Error recovery operations can be done remotely and efficiently, preventing on-site operators from being late in noticing error signals and allowing on-site operators to concentrate on supplying components, thereby improving productivity and reducing manpower.

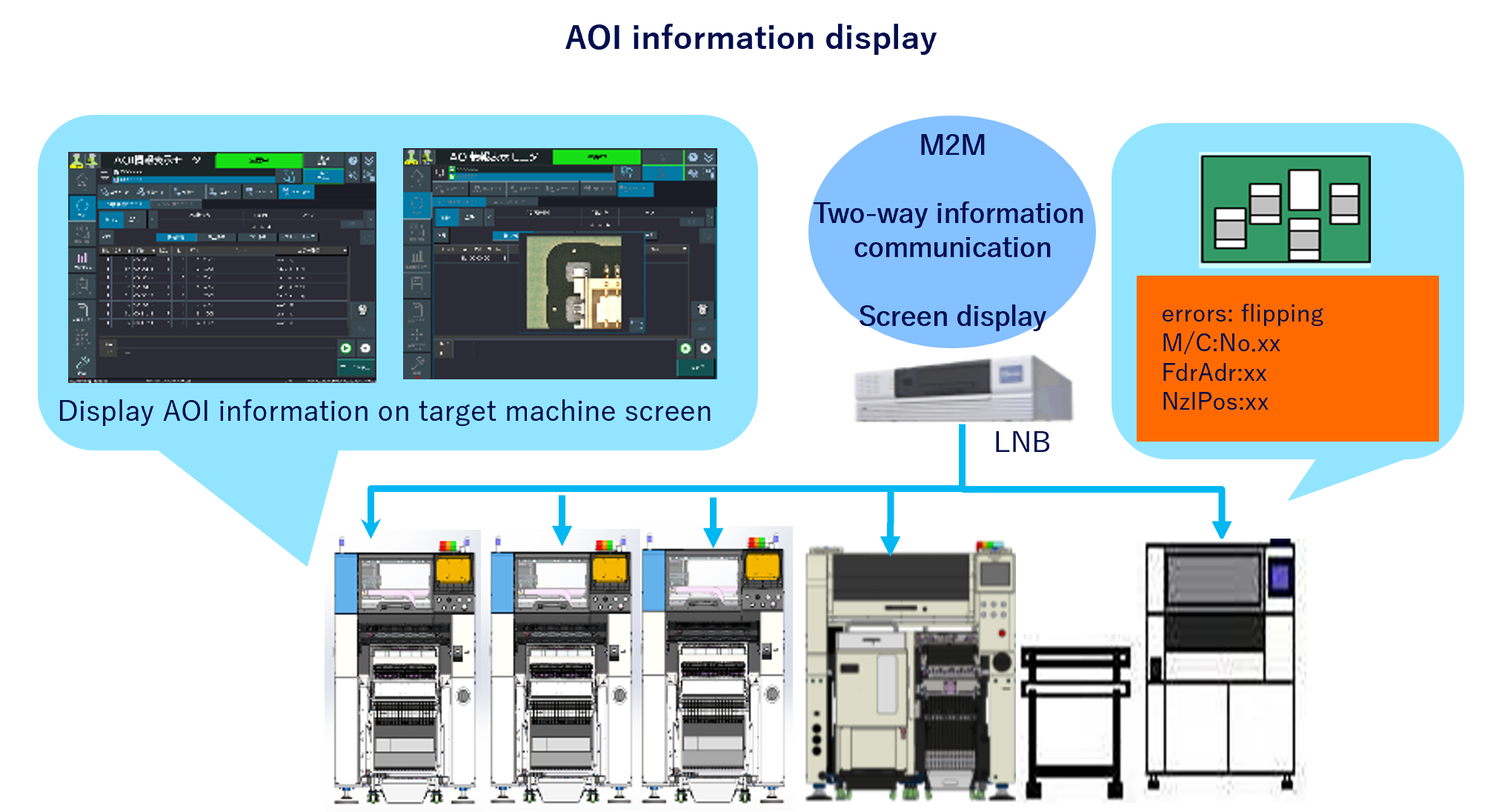

AOI information display

When a quality error occurs in AOI, quality error response can be performed skillless to improve operation rate. When a quality error occurs in AOI, information about the target device can be displayed in AOI, and AOI information including images can be displayed in the target device to respond skillless.

*The above information includes options. Also, please contact us for details, as it may differ depending on usage conditions.

New Parts Feeder

Auto Setting Feeder

Greatly reduces working time by automating parts supply work in the SMT process. ASF supports 8~104 mm width tape parts (Paper, Emboss).

Mounting MES Software

PanaCIM-EE Gen2

Support is provided for improvement in QCD in each task related to mounting, through centralized management of the entire mounting floor

Integrated Line Management System

iLNB

Optimization of the entire production line by “connecting" Panasonic machines, non-Panasonic machines, and higher-level systems

Automation for mounting-related processes

We provide automation equipment that replaces manual work for mounting-related processes, propose automated factories, and introduce automation introduction examples.

Line simulation

Tact simulation can be performed according to the mounted components and supply form.

Mounting feasibility study (nozzle selection)

We propose the optimum nozzle for the mounted components

Maintenance solution

To ensure that our mounting machines can be reliably used by our customers for many years after delivery, we not only maintain the machines, but also continue to support our customers throughout the life span of the machines, reducing production loss, stabilizing operation and improving work efficiency.

Modular Placement Machine

NPM-GH

Compatible with high productivity and placement accuracy.