GZ4 Series(YD-350GZ4 / YD-500GZ4 / YD-500GZ4TAL)

GZ4 Series

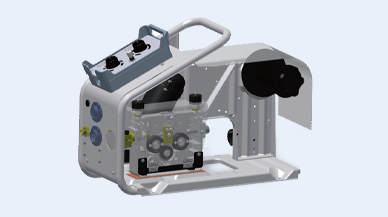

* In addition to this product (welding power source), a wire feeder, remote control unit, torch, and gas regulator are required for welding.

Key functions

-

Continuous evolution of low spatter control

-

High-precision pulsed MAG welding

-

Intuitive operation

-

Easy-to-set welding conditions

-

Output of various data to support quality control and frontline management

Equipped with voltage feedback control. This series significantly reduces spatter generated during MTS-CO2 welding and SP-MAG welding.

Equipped with HD-Pulse functions.

The HD-Pulse functions suppress undercut during high-speed welding while maintaining the quality of low spatter welding.

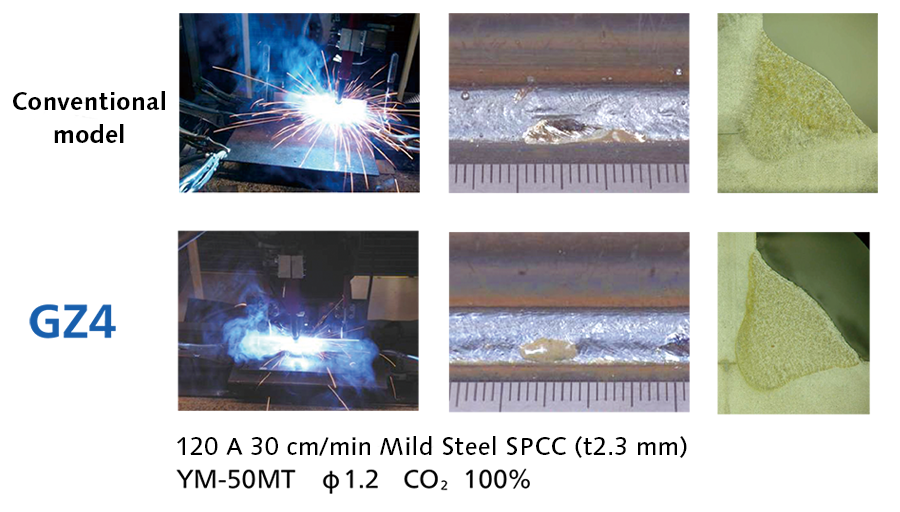

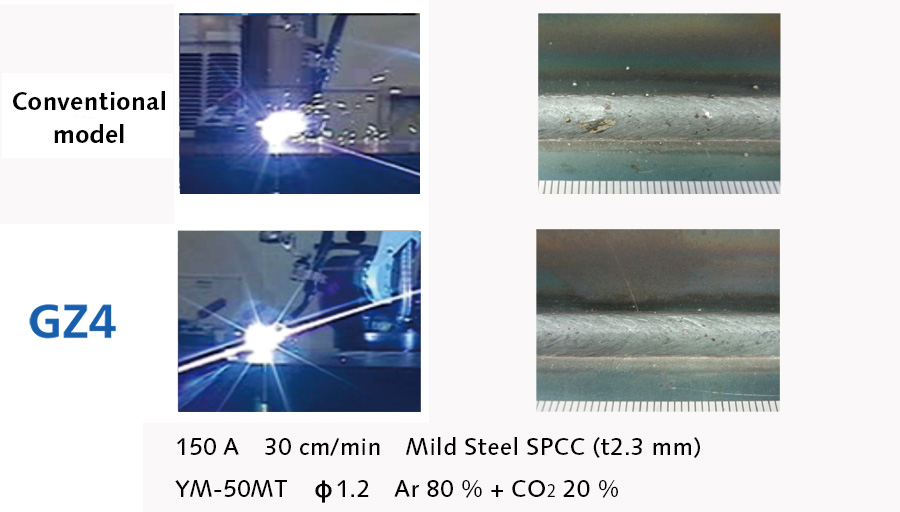

Low-spatter welding achieved by the MTS-CO2 welding method

This method suppresses the vibration of the molten pool when the reignition of the arc takes place after the short circuit is opened. In addition, it suppresses micro short-circuits that occur during the arc period, thereby reducing the amount of spatter by up to 70 %.

MTS : Metal Transfer Stabilization Control

Low-spatter and high-quality achieved by the SP-MAG welding method

The current is superimposed immediately after short circuit opening to increase the melting rate of the wire tip, thereby making the next short-circuiting smoother and shortening the cycle. This reduces the amount of spatter by up to 85 %.

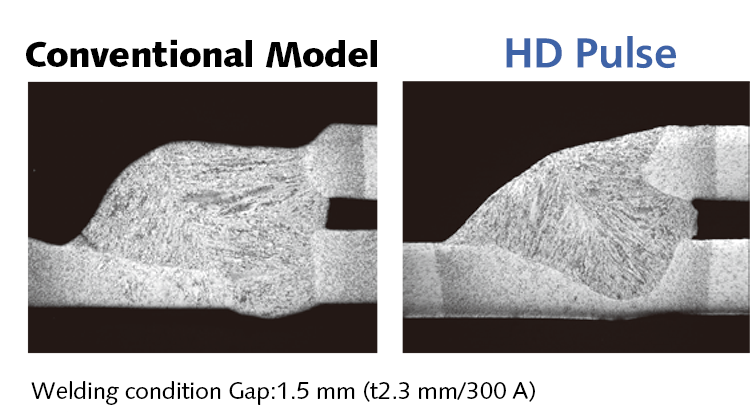

The HD-Pulse welding method achieves reduced heat input and low spatter welding

HD-Pulse welding can achieve a shorter arc length and narrower molten pool compared to conventional pulse MAG welding, thereby achieving higher-speed welding. Furthermore, undercut is suppressed and gap tolerance is improved. It is ideal for high-current high-speed welding of medium thickness plates.

Easy-to-understand display for intuitive operation

Users can adjust all welding-related settings at their fingertips.

●YX-25AD1

For CO2 / MAG / MIG welding

●YX-503A

For aluminum MIG welding

Please purchase separately as necessary.

| Model number | YD-350GZ4 | YD-500GZ4 | |

|---|---|---|---|

| Rated input voltage*1 | V | 200 AC*1 (allowable fluctuation range:180 to 242) | |

| Number of phases, rated frequency | ー | 3-phase, 50 / 60 Hz | |

| Rated input | kVA | 17.7 | 28.8 |

| Rated input | kW | 16.0 | 27.5 |

| Maximum open circuit voltage | V | 78 DC | 82 DC |

| Rated duty cycle (10-minute cycle) | % | 60 | 100 |

| Output current adjustment range | A | 30 to 350 DC | Without pulse: 30 to 500 DC With pulse: 30 to 400 DC |

| Output voltage adjustment range | V | 12 to 36 DC | 12 to 45 DC |

| Control method | ー | IGBT inverter type | |

| Memory functions | ー | 50-channel storage and reproduction | |

| Applicable welding process | ー | CO2 / MAG / MIG | CO2 / MAG / MIG / Pulsed MAG / Pulsed MIG |

| Waveform control function | ー | Digital setting | |

| Applicable shielding gas | ー | CO2(100 %), MAG (Ar : 80 %, CO2 : 20 %), Stainless steel MIG (Ar : 98 %, O2 : 2 %) | |

| Applicable wire diameter | mm | 0.8 / 0.9 / 1.0 / 1.2 | 1.2 / 1.4 / 1.6 |

| Applicable wire materials | ー | Mild steel / Mild steel FCW / Stainless steel / Stainless steel FCW | |

| Pre-flow time | s (seconds) | 0.0 to 10.0 (adjustable in 0.1 increments) | |

| Post-flow time | s (seconds) | 0.0 to 10.0 (adjustable in 0.1 increments) | |

| Arc spot time | s (seconds) | 0.3 to 10.0 (adjustable in 0.1 increments) | |

| Input power supply terminal | ー | Terminal block (M5 bolt fixing) | |

| Output terminal | ー | Steel plate terminal (with M8 bolt) | |

| External dimensions (width x depth x height)*2 | mm | 380 × 550 × 640 | 378 × 543 × 896 |

| Mass | kg | 52 | 77 |

*1: Supports nominal voltages of 200/220 V.

*2: The depth dimension does not include the input power supply terminal cover on the rear panel.

* Voltage detection wire (5 m) included.

● View the required power supply capacity and cable thickness data

開催予定のセミナーや展示会情報をまとめて掲載しています。

また、過去のセミナーや展示会情報も掲載しています。

溶接のスペシャリストが溶接に関するお悩みに対し、実ワークで施工提案いたします。

パナソニックは全世界のお客様を支援する体制を整えております。日本から海外の工場へ生産展開するお客様も安心して当社設備をご使用いただけます。

パナソニック松溶会に加盟している方向けの特設ページです。

会員サイトP-Webへの申請書をダウンロードすることができます。

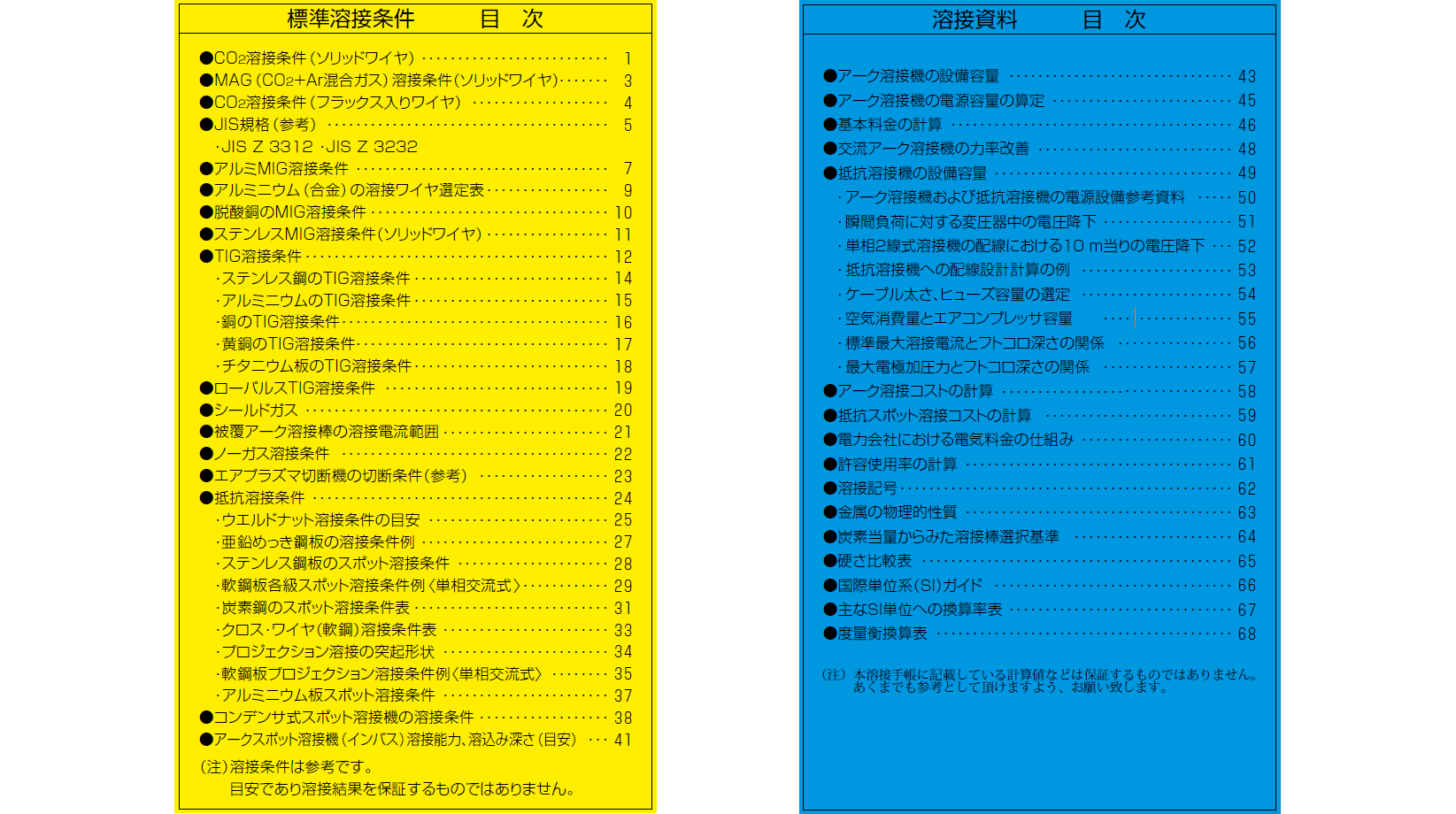

溶接機に必要な設備や溶接条件など、お客様のお困りごとを解決するお役立ち情報満載の「溶接手帳(溶接関連資料)」はこちらからダウンロードすることができます。

溶接関係のSDSを、PDFファイルでご用意しています。

当ホームページでは、労働安全衛生法と化管法に準拠したSDSを掲載しております。

外形寸法の確認や導入時のレイアウト検討などにご使用いただけます。各種ロボットの2D・3D CADデータはこちらからダウンロードすることができます。

Panasonic has established a system to support customers all over the world. Customers expanding production from Japan to overseas factories can also use our equipment with peace of mind.

Website dedicated page for members of Panasonic Shoyokai. You can download the application form to join the membership website P-Web.