YC-300BC2

* In addition to this product (welding power source), a torch and gas regulator are required for welding.Key functions

-

Reduces noise through an arc start without using high frequencies. Also reduces electrode wear

-

Improved arc start performance that is ideal for welding for plant construction, etc.

-

Versatile waveform control that can be selected according to the application

-

Case structure with improved transportability and storage efficiency enables stacking

-

3-phase / single-phase, 200 / 220 V, 50 / 60 Hz (common)

High frequencies are not used when starting the arc, thereby reducing the impact of noise on other electronic devices. Furthermore, this model is equipped with a noise filter as standard.

This model achieves a stable output with high-speed control 1.6 times faster than conventional inverter machines. It is also equipped with energy saving functions.

The body is 7 kg lighter than conventional models. This product has adopted a case structure, allowing it to be vertically stacked in two tiers for transportation or three tiers for storage, thereby enabling effective use of space.

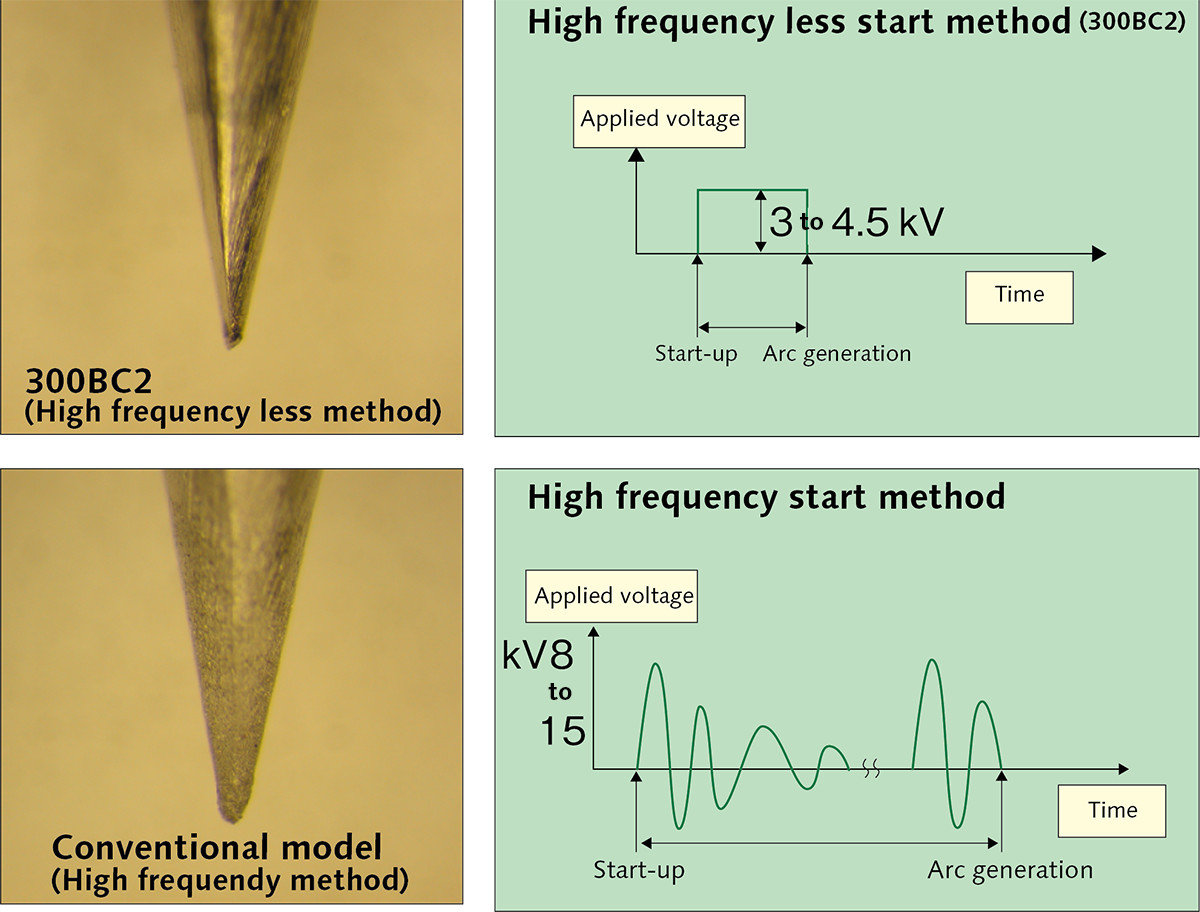

Noise reduction through an arc start without using high frequencies

Since no high frequencies are used when starting the arc, high frequency noise that affects other electronic devices is suppressed. Since the electrode surface is not roughened, the service life of the electrode is extended and stable operation can be performed even during frequent arc starts.

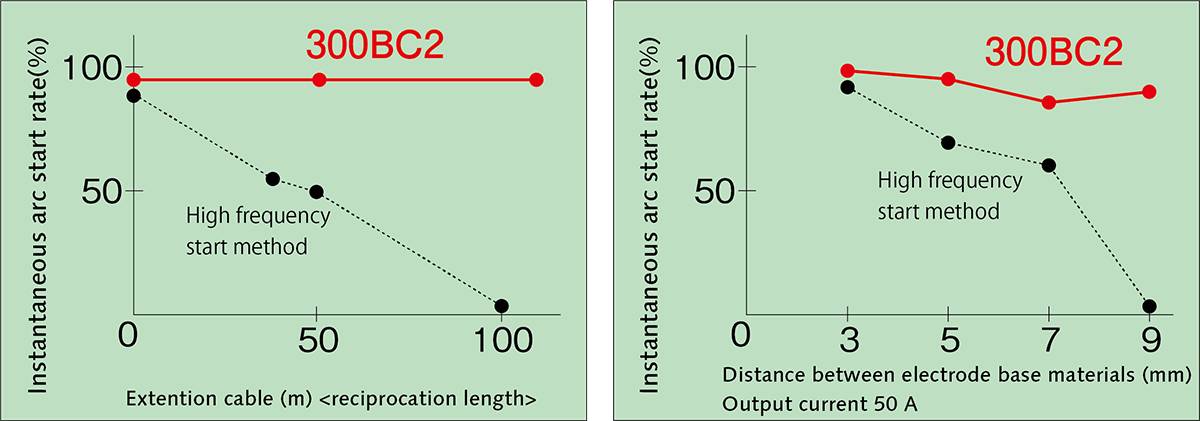

Improved arc start performance ideal for tack welding

The adoption of arc starts without using high frequencies has improved the arc start performance. Instantaneous starts are possible even when performing repetitive operations, such as for tack welding or when using an extension cable, making it ideal for welding in plant construction.

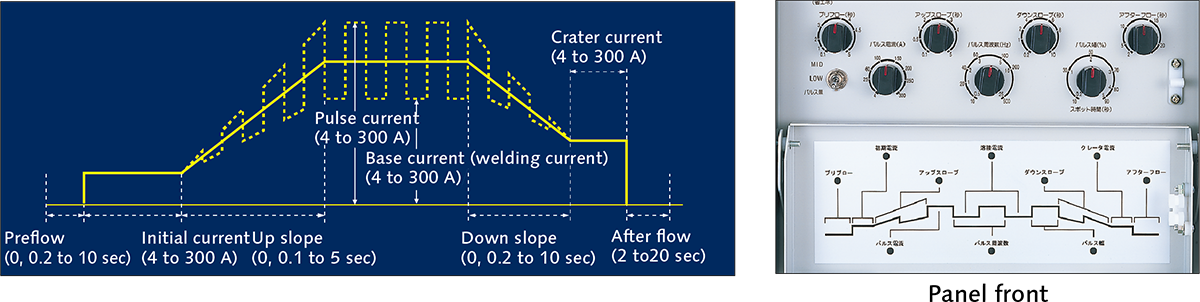

Versatile waveform control that can be selected according to the application

Equipped with various welding waveforms for middle pulse control (effective for thin plate welding) and low pulse control (optimal for medium to thick plate welding) as well as initial current control and other control for uniform welding. Settings can be performed on the front panel.

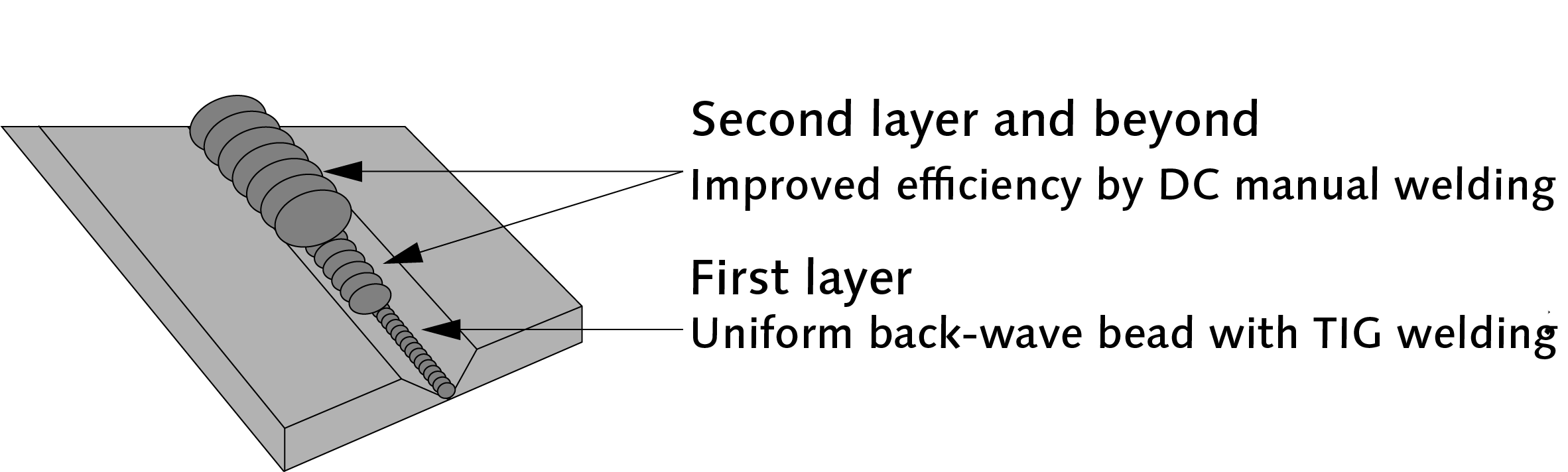

Effective even for DC manual welding

This product achieves high-quality welding of mild steel, stainless steel, high-tensile steel, Cr-Mo steel, etc., and can increase the efficiency of additional welding of the second and subsequent layers after TIG welding.

Effective check and protection functions

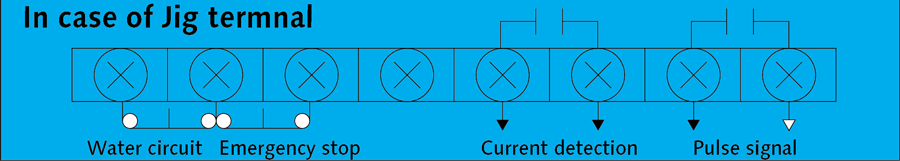

This product is equipped with an error indicator, power switch with a no-fuse breaker, electric shock prevention function, and connection terminals for various jigs.

Compact and lightweight case structure

This product has achieved a 7 kg lighter body than conventional machines. A case structure has been adopted for the ease of transportation and storage. The units can be stacked vertically up to two tiers for transportation and up to three tiers for storage.

Torches for TIG welding

● Various types with rated currents from 80 to 300 A

(Standard cables with lengths of 4 m and 8 m are available)

●YX-251A

For argon gas welding

●YC-301URTRK1

* With a 5 m long extension cable

| Model number | ー | YC-300BC2 | |||

|---|---|---|---|---|---|

| Rated input voltage and frequency | ー | 200 / 220 V ± 10% (common), 50 / 60 Hz (common) | |||

| Number of phases | ー | Single-phase | 3-phase | ||

| Rated input | kVA(kW) | 10.4 (6.5) | 14.0 (10.2) | ||

| Applicable welding process (DC) | ー | TIG (pulse TIG acceptable), arc spot, manual welding | |||

| Rated output current | DC TIG | A | 180 DC | 300 DC | |

| Manual welding | A | 180 DC | 250 DC | ||

| Rated output voltage | DC TIG | V | 17.6 DC | 20 DC | |

| Manual welding | V | 28 DC | 30 DC | ||

| Rated duty cycle (10-minute cycle) | % | 40 | |||

| Maximum open circuit voltage | V | 80 DC | |||

| Output current adjustment range | Initial current, crater current, pulse current | A | 4 to 180 | 4 to 300 | |

| Welding current | TIG, spot | A | 4 to 180 | 4 to 300 | |

| Manual welding | A | 4 to 180 | 4 to 250 | ||

| Up-slope time | s (seconds) | 0 or 0.1 to 5 | |||

| Down-slope time | s (seconds) | 0 or 0.2 to 10 | |||

| Pre-flow time | s (seconds) | 0 or 0.2 to 10 | |||

| Post-flow time | s (seconds) | 2 to 20 | |||

| Arc spot time | s (seconds) | 0.2 to 5 | |||

| Pulse frequency | Middle pulse | Hz | 10 to 500 | ||

| Low pulse | Hz | 0.5 to 25 | |||

| Pulse width | % | 10 to 90 | |||

| Control method | ー | IGBT inverter type | |||

| TIG welding starting method | ー | DC high-voltage start method | |||

| Crater control | ー | On, Off, Repeated (Arc stop when Repeated is selected: By pulling up the torch) | |||

| Electrical shock prevention (during manual welding) | ー | Factory default: ON (23 V) | |||

| Cooling method | ー | Forced air cooling (exhalation) (with a power saving function during TIG and spot welding) | |||

| Insulation type | ー | Type H | |||

| External dimensions (width x depth x height)*1 | mm | 288 × 520 × 552 | |||

| Mass | kg | 41 | |||

*1: The depth dimension does not include the input power supply terminal cover on the rear panel.

● View the required power supply capacity and cable thickness data

Panasonic has established a system to support customers all over the world. Customers expanding production from Japan to overseas factories can also use our equipment with peace of mind.

Website dedicated page for members of Panasonic Shoyokai. You can download the application form to join the membership website P-Web.