YE-200BL3

200BL3 Catalog

* This product is sold as a set. A welding power source, torch, and gas regulator are included.

Key functions

-

Lightweight and compact body that is easy to use on site

-

Stable welding quality

-

Simple and easy-to-use operation

Full digital control enables a good arc start and precise welding current setting. This series prevents variations in welding conditions and enables high-quality welding.

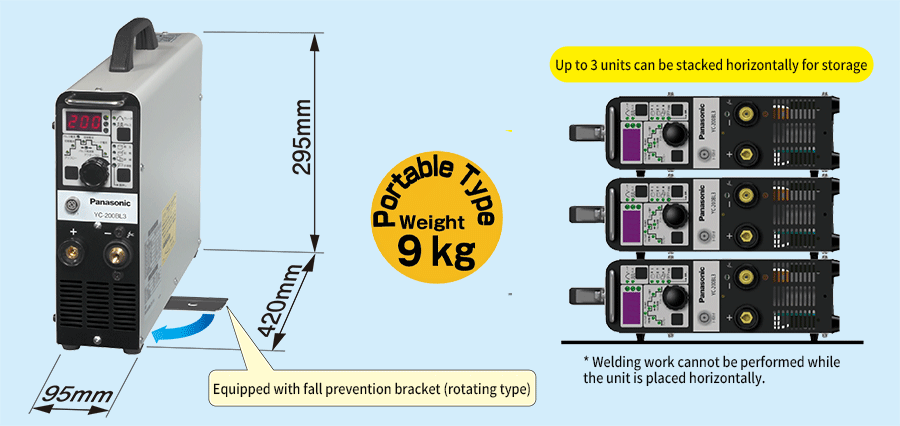

Despite its all-sheet-metal structure and robust body, it weighs only 9 kg. Comes with a metal fitting to prevent it from overturning, making users feel free to bring it to locations for on-site welding.

Equipped with welding condition storage and reproduction functions (9 channels) as standard. The functions are convenient for frequent on-site welding, enabling users to manage welding conditions for each joint shape or plate thickness, or standardize the setting conditions to ensure stable quality.

Compact body designed for on-site welding

The main unit width is kept to 95 mm, making it easy to carry around with one hand. Although this product possesses a robust body with an entirely sheet metal structure, it has achieved a compact and lightweight body weighing only 9 kg. The input voltage range of 170 to 253 V allows a stable operation regardless of the on-site power supply conditions.

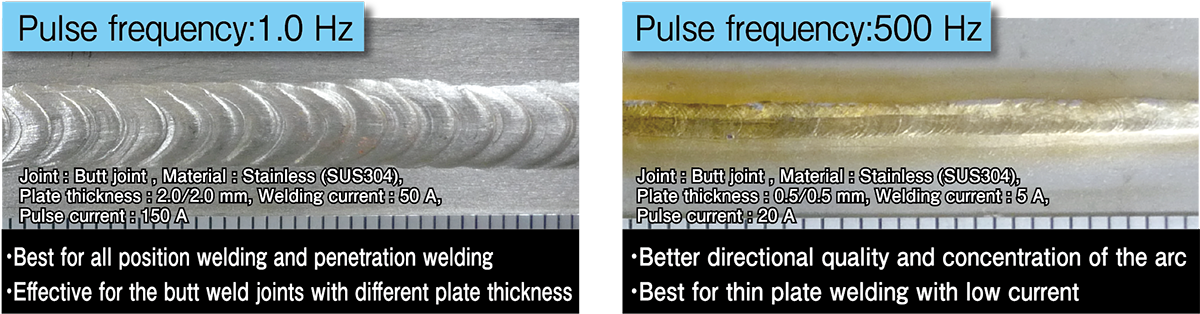

Equipped with DC pulse functions as standard

Enables the setting of 0.5 to 500 Hz. Achieves high-quality welding tailored to the workpieces.

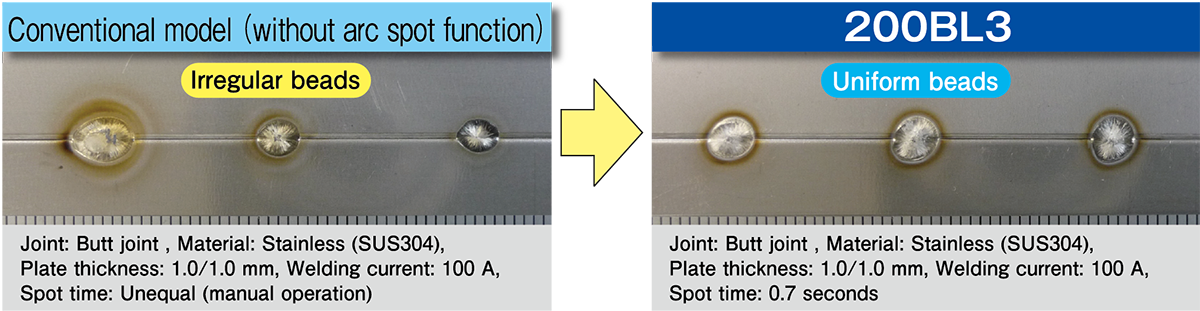

Equipped with arc spot functions

Enables the digital setting of 0.1 to 5.0 seconds (in 0.1-second increments). Stabilizes the welding quality with a uniform bead appearance and good penetration.

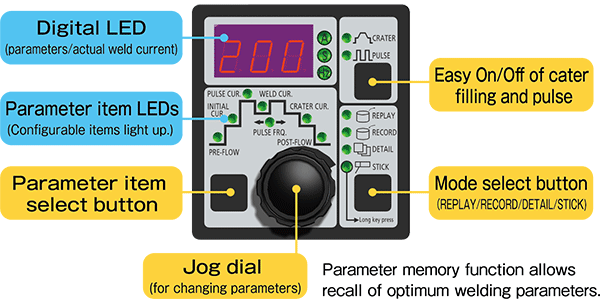

Easy to operate with an LCD and simple button layout

This product can be operated with a large jog dial and three buttons. The welding condition memory (9 channels) enables storage and reproduction of welding conditions according to the workpiece.

Examples:

- On-site welding: As a data bank to manage welding conditions for each joint shape and plate thickness

- Light work: As a notepad to keep track of welding conditions

- Production site: For standardizing welding conditions to ensure stable quality

- Skill training: As a tool for passing on skills for managing difficult settings for TIG welding

| Model number | YE-200BL3 | |||

|---|---|---|---|---|

| Welding power source | YC-200BL3 | |||

| Rated input voltage | ー |

Single-phase, 200 V ± 15%, 50 / 60 Hz |

||

| Allowable fluctuation range | V | 170 to 253 | ||

| Rated input | ー | 7.3 kVA, 4.8 kW | ||

| Maximum open circuit voltage | V | 65 DC | ||

| Rated output current | DC TIG | A | 200 DC | |

| DC manual welding | 150 DC | |||

| Rated output voltage | DC TIG | V | 18 DC | |

| DC manual welding | 26 DC | |||

| Rated duty cycle (10-minute cycle) | % | 20 | ||

| Output current adjustment range | DC TIG | A | 5 to 200 | |

| DC manual welding | 5 to 150 | |||

| Up-slope time | S | 0.0 to 10.0 (in 0.1 s increments) | ||

| Down-slope time | S | 0.0 to 10.0 (in 0.1 s increments) | ||

| Pre-flow time | S | 0.0 to 25.0 (in 0.1 s increments) | ||

| Post-flow time | S | 0.0 to 25.0 (in 0.1 s increments) | ||

| Arc spot time | S | 0.1 to 5.0 (in 0.1 s increments) | ||

| Pulse frequency | Hz | 0.5 to 500 | ||

| Pulse width | % | 50 (fixed) | ||

| Applicable welding process | ー | DC TIG, DC manual welding | ||

| Control method | ー | IGBT inverter type | ||

| Sequence functions | ー | Crater control: On, Off | ||

| TIG welding starting method | ー | High-frequency start method | ||

| Cooling method | ー | Forced air cooling | ||

| Applicable shielding gas | ー | Ar: 100%* | ||

| Memory functions | ー | 9-channel storage and reproduction | ||

| External dimensions (width x depth x height) | mm | 95 x 420 x 295 (projections not included) | ||

| Main unit mass (power cord not included) | kg | 9 | ||

| TIG torch | YT-15TS2TAD | |||

| Output current / duty cycle | ー | 150 A / 35% (200 A / 20%) | ||

| Torch cable | m | 8 | ||

| Argon gas regulator | YX-16AG1 | |||

* Please use high purity argon gas for welding conforming to JIS-K1105 (purity 99.9% or higher).

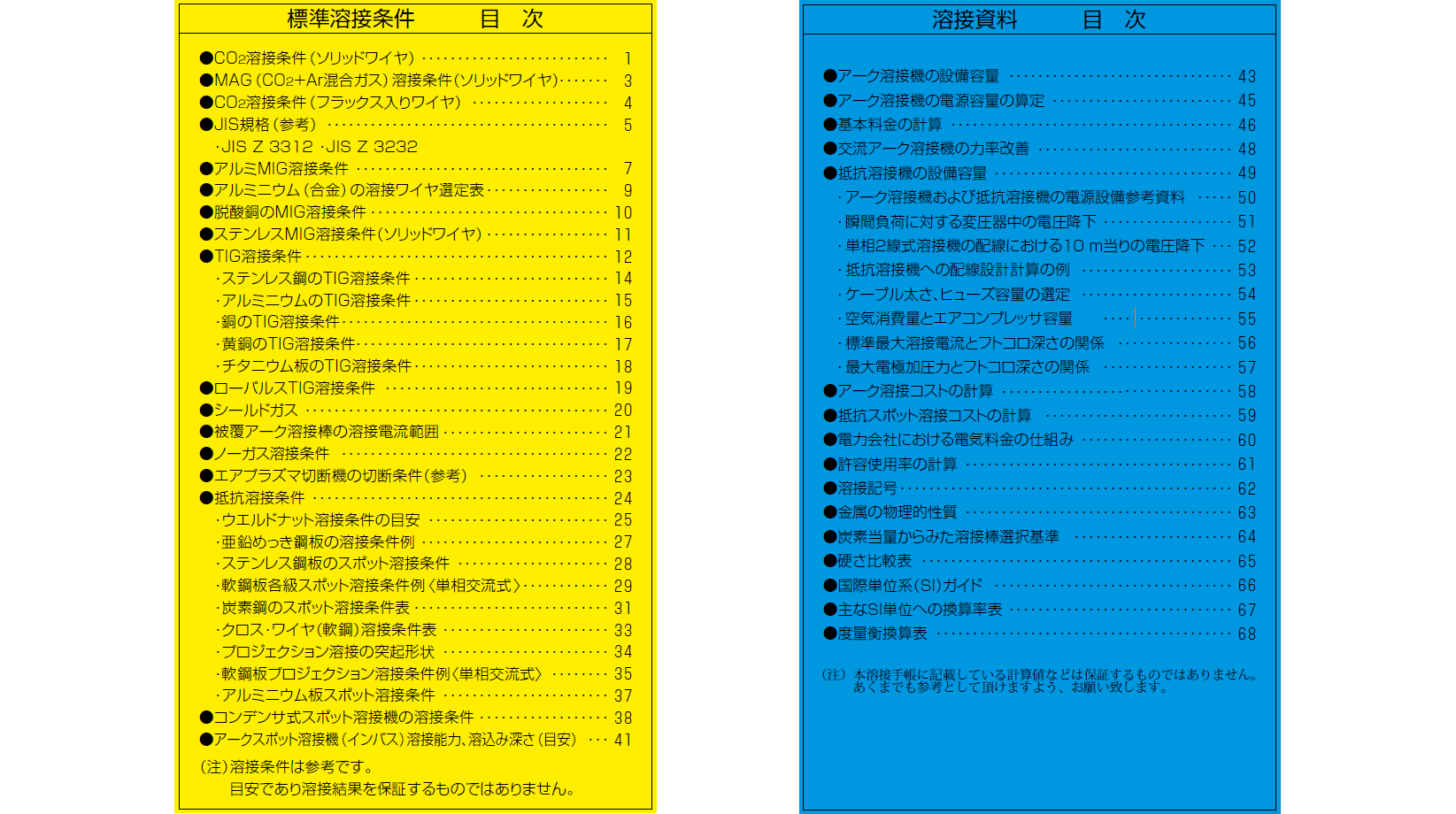

● View the required power supply capacity and cable thickness data

開催予定のセミナーや展示会情報をまとめて掲載しています。

また、過去のセミナーや展示会情報も掲載しています。

Panasonic has established a system to support customers all over the world. Customers expanding production from Japan to overseas factories can also use our equipment with peace of mind.

Website dedicated page for members of Panasonic Shoyokai. You can download the application form to join the membership website P-Web.

溶接のスペシャリストが溶接に関するお悩みに対し、実ワークで施工提案いたします。

パナソニックは全世界のお客様を支援する体制を整えております。日本から海外の工場へ生産展開するお客様も安心して当社設備をご使用いただけます。

パナソニック松溶会に加盟している方向けの特設ページです。

会員サイトP-Webへの申請書をダウンロードすることができます。

溶接機に必要な設備や溶接条件など、お客様のお困りごとを解決するお役立ち情報満載の「溶接手帳(溶接関連資料)」はこちらからダウンロードすることができます。

溶接関係のSDSを、PDFファイルでご用意しています。

当ホームページでは、労働安全衛生法と化管法に準拠したSDSを掲載しております。

外形寸法の確認や導入時のレイアウト検討などにご使用いただけます。各種ロボットの2D・3D CADデータはこちらからダウンロードすることができます。