YC-200TRC

* In addition to this product (welding power source), a torch and gas regulator are required for welding.Key functions

-

This three-in-one machine for TIG welding, manual welding, and air plasma cutting increases operation rates

-

Versatile waveform control tailored to applications

-

Allows quick switching between cutting and welding

-

Compact and lightweight machine ideal for on-site welding

In addition to TIG welding, this product supports DC manual welding. It is equipped with versatile waveform control, and possesses sufficient functionality even as a machine specialized for welding.

This product is less-expensive than purchasing a welding machine and cutting machine separately. It requires a storage space for only one unit.

Customers can use the cables and torches they are accustomed to using.

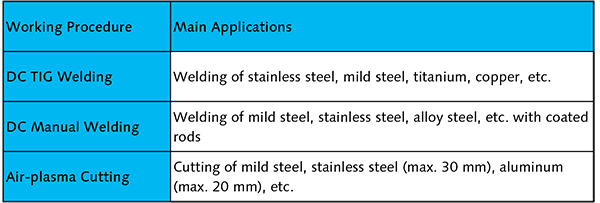

Three-in-one machine applicable in various situations

TRC can be used as a TIG welding machine, a DC manual welder, and an air plasma cutting machine. Users can switch functions between cutting and welding while the cables are connected. Equipment expenses can be reduced compared to cases where machines are purchased separately. The storage space can also be saved.

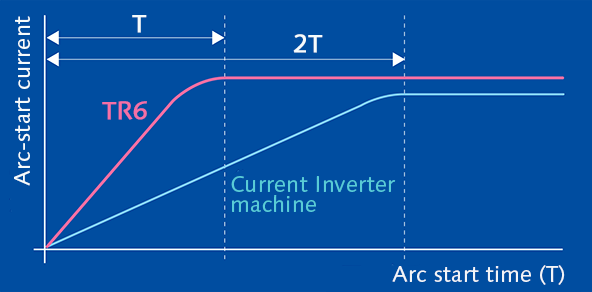

High-performance and stable arc

Arc convergence and stability have been improved by the control that is 1.6 times faster than conventional inverter machines. A stable arc performance can be achieved from 4 A to the rated current. Furthermore, by adopting a new circuit, the startup speed has been approximately doubled, enabling more efficient welding.

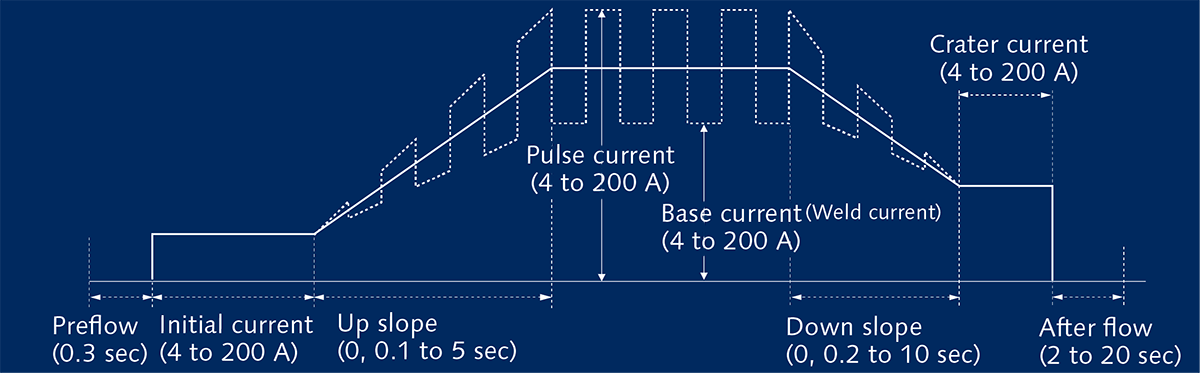

Versatile waveform control that can be selected according to the application

Equipped with various welding waveforms for middle pulse control (effective for thin plate welding) and low pulse control (optimal for medium to thick plate welding) as well as initial current control and other control for uniform welding. Settings can be performed on the front panel.

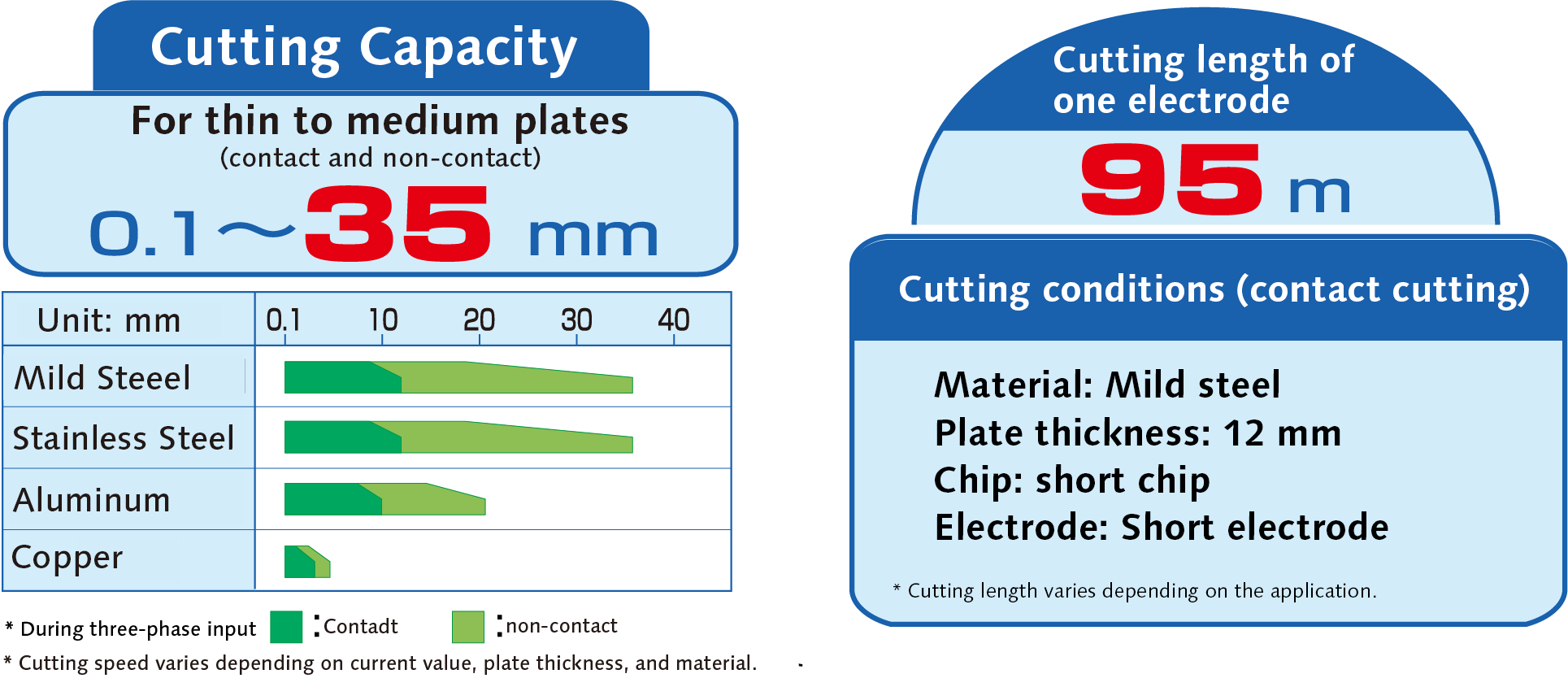

Air plasma cutting can be applied to plates with thicknesses ranging from 0.1 to 35 mm.

Capable of cutting thin to medium plates (contact and non-contact) with thicknesses ranging from 0.1 to 35mm. The unit is compact and lightweight, making it ideal for on-site welding.

● Various types with rated currents from 80 to 300 A (Standard cables with lengths of 4 m and 8 m are available)

●YX-251A

For argon gas welding

| Model number | YC-200TRCT00 | |||

|---|---|---|---|---|

| Rated input voltage | V | 200 / 220 AC (allowable fluctuation ranges: 180 to 220 for the rated voltage of 200 V; 198 to 242 for the rated voltage of 220 V) |

||

| Number of phases, rated frequency | ー | Single-phase / 3-phase, 50 / 60 Hz | ||

| Rated input | ー | Single-phase | 3-phase | |

| 8.1 kVA(5.1 kW) | 12.1 kVA(10.3 kW) | |||

| Maximum open circuit voltage | V | 80 DC (290 when cutting) | ||

| Rated duty cycle (10-minute cycle) | % | 40 (60 when cutting with 3-phase input) | ||

| Output current adjustment range | DC TIG | A | 4 to 150 | 4 to 200 |

| DC manual welding | 4 to 150 | 4 to 200 | ||

| Cutting | 10 to 40 | 10 to 60 | ||

| Control method | ー | IGBT inverter type | ||

| Applicable welding process | ー | DC TIG, DC manual welding | ||

| Applicable shielding gas (welding) | ー | Ar: 100% | ||

| Up-slope time | s (seconds) | 0*1 or 0.1 to 5 | ||

| Down-slope time | s (seconds) | 0*1 or 0.2 to 10 | ||

| Pre-flow time | s (seconds) | 0.3 | ||

| Post-flow time | s (seconds) | 2 to 20 | ||

| Pulse frequency | Hz | 0 or 0.5 to 25 | ||

| Air for cutting | ー | External supply type | ||

| Input power supply terminal | ー | Terminal block (M5 bolt fixing) | ||

| Output terminal | ー | Copper plate terminal (with M8 bolt) | ||

| External dimensions (width x depth x height) |

mm | 288 x 579 x 581*2 | ||

| Mass | kg | 49 | ||

*1: The setting of 0 seconds needs to be performed on the PCB.

*2: When the air unit is not installed.

* When using this product with single-phase input power, connect the input terminals to the "U" and "V" phases.

* With a 3 m long gas hose

● View the required power supply capacity and cable thickness data

Panasonic has established a system to support customers all over the world. Customers expanding production from Japan to overseas factories can also use our equipment with peace of mind.

Website dedicated page for members of Panasonic Shoyokai. You can download the application form to join the membership website P-Web.