Videos of case studies of actual problems that have been solved.

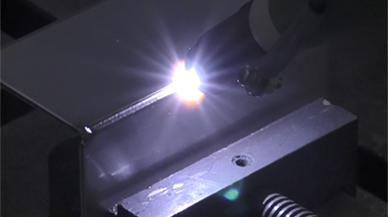

Automation of TIG welding

Thin plate TIG welding requiring proficient techniques. Once taught, TAWERS can reproduce the skills of an experienced TIG welder repeatedly.

Reduction of spatter removal man-hours

Super Active TAWERS solves the problems of spatter removal. Welding with almost no generation of spatter can be realized.

Reduction of tact time

High-speed welding with TAWERS. With the S-AWP manufacturing method, welding can be performed at more than twice the speed of conventional welding methods. (Compared with conventional)

Burn through in thin plate welding

Control of weld heat input when welding thin plates is difficult and burn through is the biggest challenge. Heat input control software solves.

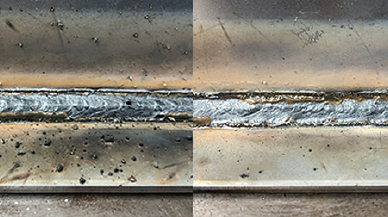

Welding of zinc-coated steel

Defect-free welding is realized with less spatter and blowholes.

Welding Power Source Integrated Robot “TAWERS”.

The robot itself has direct full control of the welding waveform and can handle a variety of welding styles with the addition of applications.

We will also introduce various concrete examples of TAWERS.

Panasonic has established a system to support customers all over the world. Customers expanding production from Japan to overseas factories can also use our equipment with peace of mind.

Website dedicated page for members of Panasonic Shoyokai. You can download the application form to join the membership website P-Web.